In the realm of woodworking, achieving a smooth and flawless finish is crucial. The woodworking sander machine has become an indispensable tool for both professional woodworkers and hobbyists. These machines are designed to sand and smooth wood surfaces, preparing them for finishing or further processing.

Woodworking Sander Machine

A woodworking sander machine is a power tool designed to smooth and finish wood surfaces by abrasion with sandpaper. These machines come in various types and sizes, each suited for specific sanding tasks. They are equipped with features such as adjustable speed controls, dust collection systems, and ergonomic designs to enhance efficiency and user comfort.

It has the features of simple operation, high degree of automation, high production efficiency, mature and stable technology, and complete supporting facilities. It can be perfectly connected with automatic CNC machines to form various automatic production lines.

CNC sanding machine is suitable for grinding and polishing all kinds of solid wood doors, European-style wooden doors, cabinet doors, plastic doors, shutters, furniture parts, carved flower panels, hollow grids, white blanks, primers and abrasive cloth strips of different thicknesses. , The polishing effect can reach 80%, which greatly saves labour and improves efficiency.

CNC Wood Sanding Machine Advantages

1. The machine structure design is reasonable, simple and beautiful, which adopts top brand laser cutting process, the workpiece first pickling rust, dry powder heating uniform coating.

2. The speed of feeding and thickness of the sanding machine can be sufficiently adjustable.

3. Reasonable design: independent operation of the cabinet, convenient usage and maintenance.

4. The CNC machine has thickness adjustment function, which can achieve rapid positioning of the thickness of plate, both accurate production, but also greatly improve production efficiency.

5. The sanding machine with high quality and stability is easy to control.

6. The CNC machine will take the place of traditional handicraft sanding and it can implement polishing on both top and bottom sides, which has greatly improved the production efficiency.

7. The products that are polished by the CNC machine have a good flatness on the surface, preparing well for the next coating.

Applications of Woodworking Sander Machines

Sand Machine for Wood Furniture

In furniture making, woodworking sander machines are essential for achieving smooth and polished surfaces. Applications include:

- Surface Preparation: Sanding wood surfaces before staining or painting.

- Edge Sanding: Smoothing edges and corners of furniture pieces.

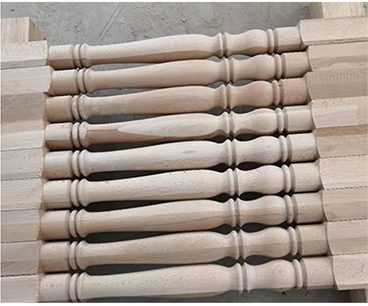

- Detail Work: Sanding intricate details and carvings.

Sand Machine for Cabinetry

The cabinetry industry relies heavily on woodworking sander machines for producing high-quality cabinets. Applications include:

- Panel Sanding: Smoothing large panels for cabinet doors and sides.

- Joint Sanding: Ensuring seamless joints and connections.

- Finish Sanding: Preparing surfaces for finishing and sealing.

Sand Machine for Flooring

In the flooring industry, woodworking sander machines are used to prepare and finish wood floors. Applications include:

- Floor Sanding: Removing old finishes and smoothing the surface.

- Edge Sanding: Sanding edges and corners of the floor.

- Refinishing: Preparing floors for new finishes and coatings.

DIY Projects and Home Improvement

For DIY enthusiasts and home improvement projects, woodworking sander machines offer versatility and ease of use. Applications include:

- Home Renovation: Sanding doors, windows, and trim.

- Craft Projects: Smoothing wood surfaces for various crafts.

- Restoration: Refinishing old furniture and wooden items.

key features and types of wood sanding machines:

- Belt Sander: Belt sanders consist of an electric motor that drives a continuous loop of sandpaper wrapped around two drums. They are effective for rapid material removal and leveling surfaces. Belt sanders are available in different sizes, including handheld portable models and larger stationary models.

- Orbital Sander: Orbital sanders, also called pad sanders or finishing sanders, use a square or rectangular sanding pad that moves in small orbital motions. They are ideal for fine sanding and achieving a smooth finish. Orbital sanders are available in both handheld and benchtop models.

- Random Orbital Sander: Random orbital sanders combine the orbital sanding motion with a random pattern, resulting in a more aggressive sanding action. This type of sander is effective for both stock removal and finishing work. Random orbital sanders are available in different sizes, including handheld and benchtop models.

- Disc Sander: Disc sanders have a rotating sanding disc mounted on a flat surface. They are suitable for flat surfaces and can be used for stock removal as well as fine sanding. Disc sanders come in various sizes, ranging from small handheld models to larger stationary models.

- Drum Sander: Drum sanders are commonly used for sanding large wooden panels, such as tabletops or door panels. They feature a rotating drum covered with sandpaper that moves across the workpiece. Drum sanders are typically larger and more suitable for professional woodworking shops.

- Oscillating Spindle Sander: Oscillating spindle sanders have a spindle with a sanding sleeve or drum that moves up and down in an oscillating motion. They are ideal for sanding curved or contoured surfaces such as chair legs or moldings. Oscillating spindle sanders are typically benchtop models.

- Combination Sanders: Some wood sanding machines offer multiple functions in one unit. For example, there are belt/disc sanders that combine a belt sander and a disc sander on the same machine, providing versatility and convenience.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.