The wood CNC router machine has transformed the woodworking industry, offering unparalleled precision, efficiency, and versatility. This advanced technology allows for intricate cuts and detailed designs on wood, making it an essential tool for both professional woodworkers and hobbyists. In this comprehensive guide, we will explore the features, benefits, and applications of wood CNC router machines, providing valuable insights for those looking to enhance their woodworking projects.

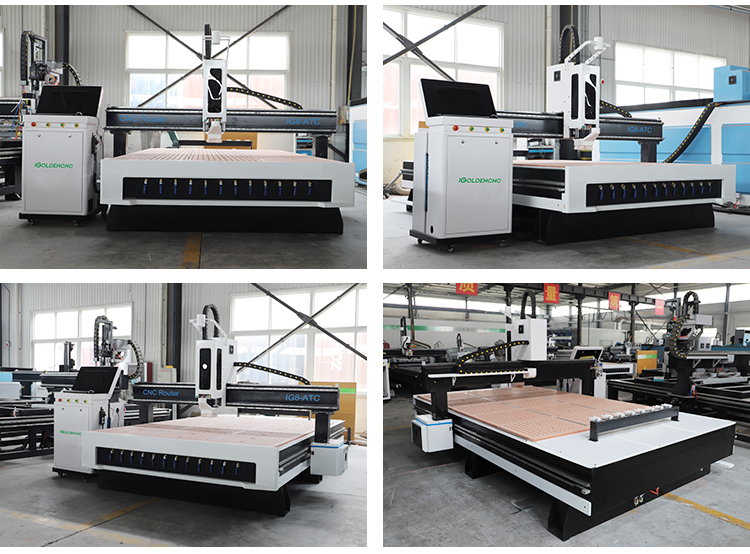

Wood CNC Router Machine

A wood CNC router machine is a computer-controlled device that uses a rotating cutting tool to carve, cut, and shape wood with high precision. The CNC (Computer Numerical Control) system automates the cutting process, allowing for complex and detailed designs that are difficult to achieve with manual methods.

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories.

The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines. The most used CNC wood router tables include 2ft by 3ft, 2ft by 4ft, 4ft by 4ft, 4ft by 6ft, 4ft by 8ft, 5ft by 10ft, and 6ft by 12ft.

A wood router is applied in most popular woodworking plans and projects such as cabinet making, door making, sign making, arts & crafts, furniture making, and home decorations. Whether you are a craft carpenter or a professional woodworker, you can easily find your next CNC router at IGOLDENCNC to automate your woodworking projects. Its user-friendliness, ease of use and multi-function make it easy for you to benefit and profit. Here is our collection of most popular CNC machines for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available. In addition, a variety of customization options and add-ons are also available to personalize your machine tools. Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

3 axis Wood CNC Router Machine

3 axis Wood CNC Router Machine

4 axis Wood CNC Router

5 axis Wood CNC Machine

Advantages of Wood CNC Router Machines

Precision and Accuracy

One of the most significant advantages of Wood CNC router machines is their precision and accuracy. Traditional woodworking methods rely heavily on manual labor, which can lead to inconsistencies and errors. CNC routers, however, are controlled by computer software, allowing for precise and repeatable cuts. This ensures that each piece is identical, which is crucial for mass production and intricate designs.

Efficiency and Speed

CNC routers significantly increase efficiency and speed in woodworking. These machines can operate continuously without fatigue, unlike human workers. They can process multiple parts simultaneously, reducing production time. Additionally, CNC routers can quickly switch between different cutting tools and operations, further enhancing productivity.

Versatility

Wood CNC router machines are highly versatile and can perform a wide range of operations, including cutting, engraving, drilling, and milling. They can handle various materials, such as hardwood, softwood, plywood, MDF, and even some plastics and composites. This versatility makes CNC routers suitable for diverse applications in different industries.

Cost-Effectiveness

Although the initial investment in a Wood CNC router machine can be substantial, the long-term cost savings are significant. CNC routers reduce material waste by optimizing cuts and minimizing errors. They also lower labor costs by automating repetitive tasks. Over time, these savings can offset the initial investment and lead to higher profitability.

Safety

CNC routers enhance safety in the workplace. Traditional woodworking tools can be dangerous, requiring close manual handling of sharp blades and cutting tools. CNC routers, on the other hand, operate within enclosed spaces and are controlled remotely via computer software. This reduces the risk of accidents and injuries, creating a safer working environment.

Customization and Flexibility

CNC routers offer unparalleled customization and flexibility. Users can easily modify designs and create custom pieces tailored to specific requirements. The ability to quickly change cutting parameters and tool paths allows for the production of unique and personalized items, catering to individual customer needs.

What Are CNC Wood Routers Used For?

These automatic machine tools are mostly used for woodworkers and carpenters to do woodworking in industrial manufacturing, small business, small shop, home business, home shop, school education. Besides, craftsman and hobbyists will also find a computer-controlled wood CNC machine useful.

Here are some of the fields where a CNC wood router will have access:

• Furniture Making: home furniture, art furniture, antique furniture, office furniture, cabinet making, door making, cabinet doors, interior doors, home doors, cupboard doors, table legs, sofa legs, wood spindles, corners, screens, headboards, composite gates, MDF projects, wood crafts, wood arts.

• Advertising.

• Die Making.

• Hollowing.

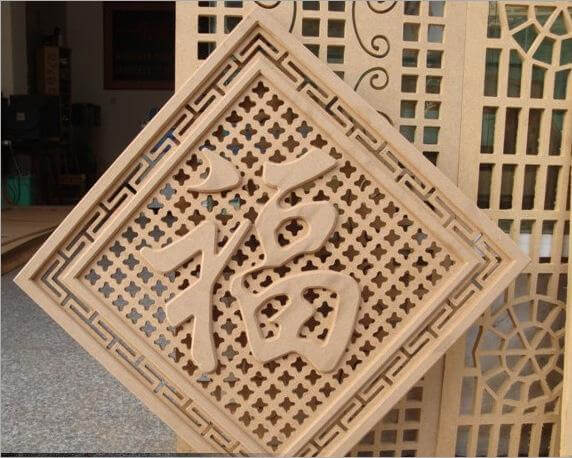

• Relief Carvings.

• Wood Cylinders.

• 3D Woodworking Projects.

• Sign Making.

• Custom Woodworking Plans.

How To Choose The Best Router Bits For Wood?

In woodworking, many details can affect the quality, accuracy and appearance of the final woodworking project, especially the selection of router bits for woodworking.

Choosing the right tool according to different processing materials and different machining processes is an important factor to ensure fast and efficient production.

What type of router bit is best for woodworking? What can each tool do in woodworking?

• Flat bottom or column router bits, mostly rely on the side edge for cutting, and the bottom edge is mainly used for flat polishing. The end face of the head of the column router bit is large, and the working efficiency is high. It is mainly used for contour cutting, milling plane, area and surface rough carving.

• Another relatively common type is straight, which is often used to carve large characters. The edge of the material cut by it is straight, which is generally used for PVC and acrylic cutting to make characters.

• Milling cutter is the most common tool in automatic woodworking. Milling cutters are divided into many types according to their shapes.

For example, double-edged spiral milling cutters used when cutting acrylic and MDF, single-edged spiral ball-end milling cutters for large deep relief processing of cork, MDF, solid wood, and acrylic. It is a prismatic milling cutter used when making high-density boards, solid wood doors, and furniture.

Of course, many tool manufacturers will also make special tools according to the special requirements of many customers, such as large chip-removing spiral milling cutters that are more suitable for cutting density boards and chip removal. The round bottom cutter is more suitable for precision small relief carving.

• The cutting edge of a ball end tool is arc-shaped, forming a hemisphere during the carving process of the wood cutting machine, the process is evenly stressed and the cutting is stable. Ball tools are not suitable for milling planes.

• Bullnose bit is a mixture of fluted column bit and ball end bit. In addition, it has the features of a ball end bit to carve curved surfaces, and on the other hand, it has the features of a fluted column bit and can be used for plane milling.

• Tapered flat bottom bits, abbreviated as tapered bits. They have the widest range of applications in the carpentry. The bottom edge of the cone bit, commonly known as the tip, is similar to a column bit, and can be used for the finishing of small planes. The side edge of the cone bit is inclined at a certain angle to form an inclined side surface during the working process.

The structural features of the cone bit can enable it to achieve the unique three-dimensional angle clearing effect of the carving industry. Cone bits are mainly used for single-line carving, area rough carving, area fine carving, 3D clear angle, projection carving, image gray scale carving.

• Tapered end mill, referred to as tapered ball nose bit. It’s a mixture of cone milling cutter and ball milling cutter. Furthermore, it has the features of a cone cutter with a small tip, and on the other hand, it has the features of a ball bit, which can mill relatively fine curved surfaces.

• Tapered bullnose bit is a mixture of cone bit and bullnose bit. Moreover, it has the features of a cone shaped bit to cut relatively fine curved surfaces, and on the other hand, it has a bullnose shaper cutter. Because of its features, the tapered bullnose router bit is often used for relief carving.

• The V-Groove router bits are designed to cut deep or shallow V-shaped grooves.

• Drill bits are mainly used for drilling. When the hole is relatively shallow, clearing bottom router bits can be used to drill holes.

Applications of Wood CNC Router Machines

Furniture Manufacturing

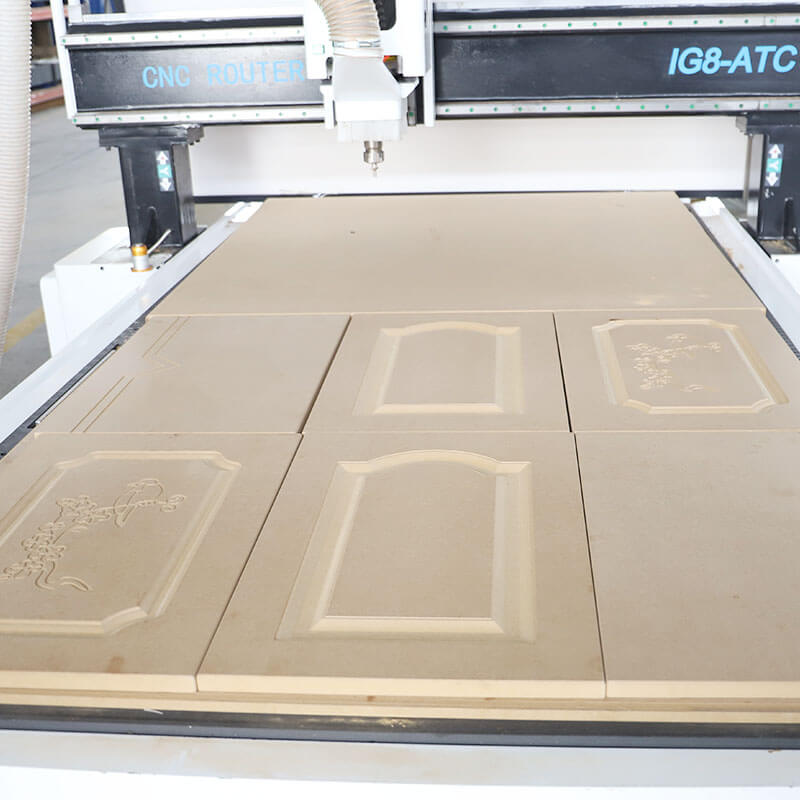

CNC routers are widely used in the furniture manufacturing industry. They can produce intricate and detailed designs, such as ornate carvings, inlays, and joinery, with high precision. CNC routers are ideal for creating custom furniture pieces, including cabinets, tables, chairs, and bed frames. The ability to automate repetitive tasks also enhances productivity in mass production.

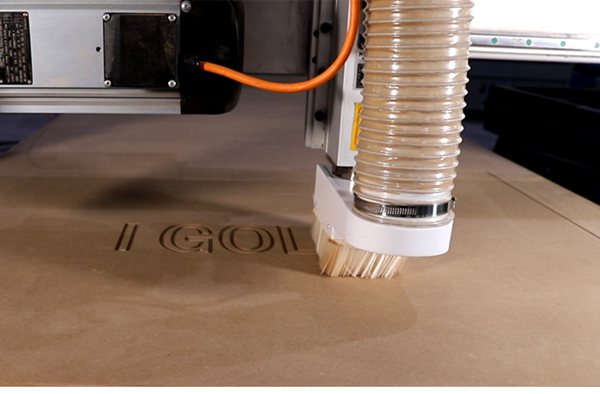

Sign Making

The sign-making industry benefits greatly from the precision and versatility of CNC routers. These machines can cut and engrave various materials, including wood, acrylic, and plastic, to create custom signs, letters, and logos. CNC routers enable sign makers to produce high-quality and visually appealing signs with intricate details and smooth finishes.

Cabinetry

CNC routers are essential tools in cabinetry, allowing for precise cutting and shaping of cabinet components. They can produce intricate door panels, drawer fronts, and decorative moldings with ease. CNC routers also optimize material usage, reducing waste and ensuring consistency in mass production. Custom cabinetry projects benefit from the flexibility and accuracy of CNC routers.

Woodworking and Carpentry

Woodworking and carpentry professionals use CNC routers to create a wide range of products, including decorative panels, moldings, trim, and architectural elements. The precision and versatility of CNC routers allow for the production of intricate designs and complex shapes that would be challenging to achieve with traditional tools.

Prototyping and Model Making

In the prototyping and model-making industries, CNC routers play a crucial role in creating accurate and detailed prototypes. These machines can quickly produce physical models from digital designs, allowing for testing and evaluation before mass production. CNC routers are also used in creating scale models for architectural and engineering projects.

Musical Instrument Manufacturing

The manufacturing of musical instruments, such as guitars, violins, and pianos, requires high precision and attention to detail. CNC routers are used to cut and shape components, such as necks, bodies, and fingerboards, with accuracy and consistency. The ability to produce intricate inlays and decorative elements enhances the aesthetic appeal of musical instruments.

Art and Sculpture

Artists and sculptors use CNC routers to create intricate and detailed pieces of art. These machines can carve and engrave wood to produce sculptures, reliefs, and decorative panels. The precision and versatility of CNC routers allow artists to bring their creative visions to life with high accuracy and consistency.

Educational Institutions

Educational institutions, such as vocational schools and universities, use CNC routers for teaching purposes. These machines provide students with hands-on experience in CNC technology and woodworking. CNC routers are valuable tools for training future professionals in various industries, including manufacturing, design, and engineering.

Types of Wood CNC Router Machines

Hobby CNC Wood Routers

Desktop CNC routers are compact and portable machines designed for hobbyists and small workshops. They are ideal for light-duty tasks and small-scale projects, such as engraving, cutting, and drilling. Desktop CNC routers are affordable and easy to use, making them suitable for beginners and educational purposes.

Benchtop CNC Routers

Benchtop CNC routers are larger and more powerful than desktop models, offering greater versatility and precision. They are suitable for small to medium-sized projects and can handle a wider range of materials. Benchtop CNC routers are popular among hobbyists, small businesses, and educational institutions.

Industrial CNC Routers

Industrial CNC routers are designed for heavy-duty applications and large-scale production. They are equipped with powerful spindles, robust frames, and advanced control systems to handle demanding tasks. Industrial CNC routers are used in various industries, including furniture manufacturing, cabinetry, and metalworking. They offer high precision, speed, and efficiency, making them ideal for mass production.

3-Axis CNC Routers

3-axis CNC routers are the most common type, operating on three axes: X (left-right), Y (forward-backward), and Z (up-down). They are suitable for most woodworking tasks, including cutting, engraving, and drilling. 3-axis CNC routers are widely used in various industries for their simplicity and versatility.

4-Axis and 5-Axis CNC Routers

4-axis and 5-axis CNC routers offer additional axes of movement, allowing for more complex and intricate operations. 4-axis routers can rotate the workpiece along the A-axis, while 5-axis routers add a B-axis for even greater flexibility. These machines are used for advanced applications, such as sculpting, prototyping, and creating detailed carvings on multiple surfaces and angles.

How Does A Wood CNC Machine Work?

A wood CNC machine uses computer signals as instructions to control the movement, timing, logic and other functions through the computer, so as to drive the spindle and bits to complete woodworking automation.

Unlike handheld, palm, plunge, plunge base, and fixed base routers, the functional software of a CNC wood router is CAD/CAM. CAD software allows users to create the designs they wish to work on a woodworking CNC machine. After completing this design, the CAM software will convert the design into a tool path code that the wood CNC machine can understand. Then, the computer converts this code into a signal that controls the movement of the drive system of the machine. The drive system includes a spindle, which is the part that saves the actual machine position. The spindle rotates 8,000 to 50,000 times per minute to cut the material. In short, the user creates a design and uses the software to make instructions for the machine.

3 axis table kit cuts along three axes at the same time: X-axis, Y-axis and Z-axis. X axis makes the router bit move from front to back, Y axis makes it move from left to right, and Z axis makes it move up and down. They are used to cut 2D flat woodworking projects.

Compared with 3 axis, 5 axis machine tools can cut along two additional axes. These automatic computer-controlled machine tools can cut five sides of a piece of material at the same time, thereby expanding the capabilities and flexibility of operators. Unlike their 3-axis counterparts, these computer-controlled 5 axis machine tools are usually used to cut large 3D woodworking projects. In addition, 5 axis table kits have a higher gantry and a longer X-axis, which allows them to cut larger woodworking projects. However, if the gantry is higher and the X-axis is longer, the accuracy and stability will be worse. For proper quality control, the height of the gantry and the length of the X-axis should be limited as much as possible. Although computer-controlled woodworking routers look like simple power tools, they are highly complex technologies and require a certain amount of expertise to operate. 5 axis CNC wood milling machines tend to be more expensive than traditional 3 axis CNC wood routers, but ultimately provide high quality, greater flexibility, allowing users to use their designs more creatively.

Choosing the Right Wood CNC Router Machine

Consider Your Needs

When choosing a Wood CNC router machine, it is essential to consider your specific needs and requirements. Determine the size and type of projects you plan to undertake, the materials you will be working with, and the level of precision and complexity required. This will help you select a machine with the appropriate specifications and features.

Evaluate the Work Area

The work area, or cutting area, is a crucial factor to consider. Ensure that the CNC router has a sufficient work area to accommodate your projects. If you plan to work on large pieces, such as furniture components or signage, choose a machine with a larger work area. For smaller projects, a compact or desktop model may suffice.

Assess the Spindle Power

The spindle power determines the machine’s ability to cut through different materials and the quality of the cuts. Higher spindle power is necessary for cutting thicker and harder materials. Evaluate the spindle’s power rating and speed range to ensure it meets your requirements.

Examine the Control System

The control system is the interface between the user and the CNC router. Look for a user-friendly control system with intuitive software and easy-to-navigate interfaces. Advanced features, such as touchscreen displays, wireless connectivity, and compatibility with popular CAD/CAM software, can enhance convenience and productivity.

Check for Additional Features

Consider additional features that can improve the machine’s performance and versatility. Automatic tool changers, dust collection systems, multi-axis capabilities, and robust construction are valuable features to look for. Assess the overall build quality and durability of the machine to ensure it can withstand continuous operation.

Read Reviews and Seek Recommendations

Reading reviews and seeking recommendations from other users can provide valuable insights into the performance and reliability of different CNC router models. Consider joining online forums and communities dedicated to CNC woodworking to gather information and learn from the experiences of others.

Budget Considerations

While it’s important to consider the initial cost of the CNC router, also factor in the long-term savings and return on investment. CNC routers can significantly reduce labor costs, material waste, and production time, leading to higher profitability. Evaluate the overall value and benefits of the machine to make an informed decision.

Conclusion

Wood CNC router machines have transformed the woodworking industry by providing precision, efficiency, and versatility. These machines offer numerous advantages, including high accuracy, increased productivity, and cost-effectiveness. With their advanced features and capabilities, CNC routers are suitable for a wide range of applications, from furniture manufacturing and cabinetry to art and sculpture.

Understanding the components, types, and features of CNC routers is essential for selecting the right machine for your needs. By considering factors such as work area, spindle power, control system, and additional features, you can make an informed decision and invest in a CNC router that meets your specific requirements.

Whether you are a hobbyist, small business owner, or professional woodworker, a Wood CNC router machine can enhance your capabilities and open up new possibilities for creativity and precision in woodworking. Embrace the power of CNC technology and take your woodworking projects to the next level with a reliable and efficient Wood CNC router machine.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.