If you’re a beginner in woodworking and want to take your craft to the next level, These machines offer precision, automation, and versatility, allowing you to create intricate designs and precise cuts with ease. However, with so many options available, choosing the right wood CNC machine for beginners can be overwhelming.

Wood CNC Machines for Beginners

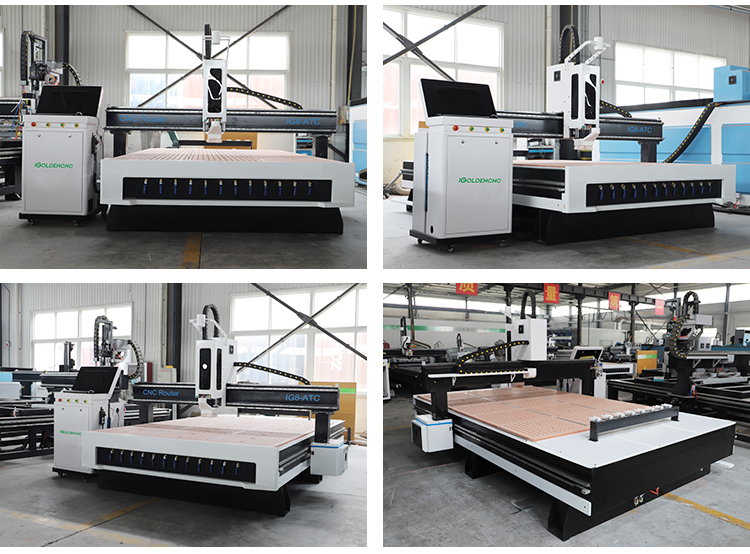

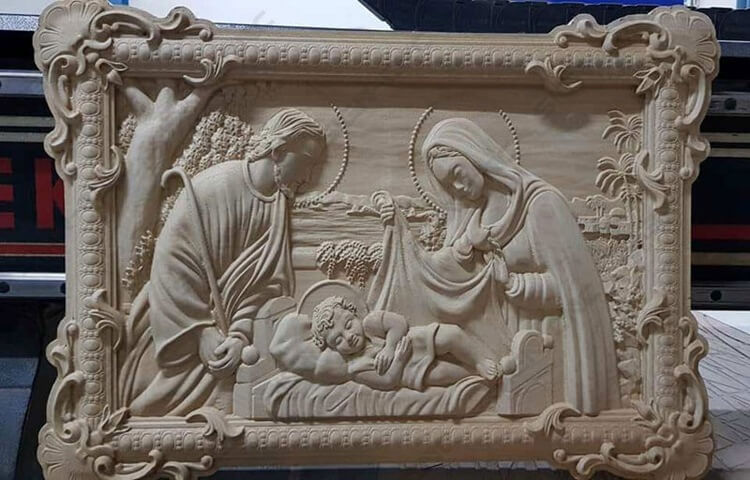

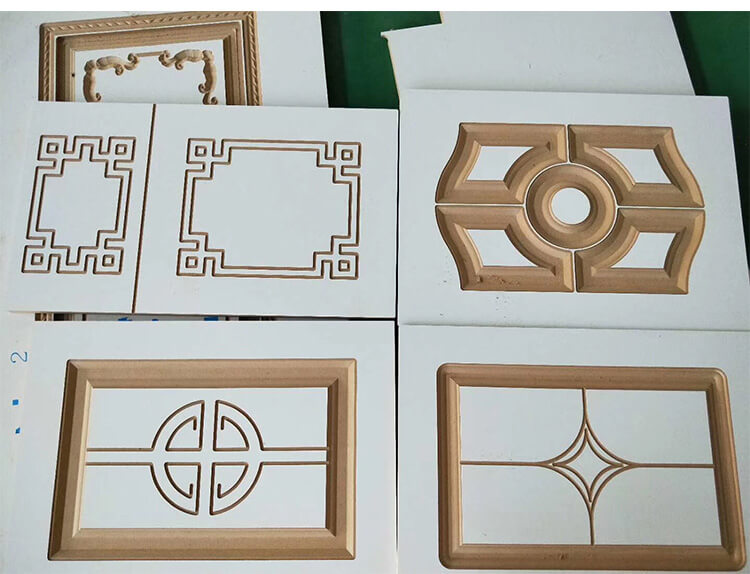

The CNC wood router is designed for carving and engraving wood, acrylic, PVC, double-colored, MDF, glass, and rubber boards. It is perfect for plane processing along the X, Y, and X axes. Both its worktable sizes and machine configurations can be customized according to users’ demands. It is widely used in cutting, carving, and engraving wood furniture, doors, cabinets, acrylic letters, signs, etc.

Wood CNC machines for beginners are specifically designed to be user-friendly and accessible to those who are new to the craft. These machines often come with simplified software interfaces, intuitive controls, and beginner-friendly features. Wood CNC machines utilize computer-controlled movements to cut, carve, and shape wood materials, offering precision and accuracy that would be difficult to achieve manually.

Types of CNC Wood Router

- By Axis: 3 axis CNC wood cutting machine, 4 axis CNC wood router, 5 axis wood CNC machine

- By Application: CNC wood engraving machine for the home shop, industrial CNC wood router, tabletop CNC wood router, hobby wood CNC router, etc.

- By CNC wood router table: CNC wood router 4×8, 2×4 wood router, 4×4 CNC wood router, etc.

Factors to Consider When Choosing a Wood CNC Machine for Beginners

1. Size and Workspace

As a beginner, it’s important to consider the size of the wood CNC machine and the available workspace in your workshop. Small to medium-sized machines are often recommended for beginners as they are easier to handle and require less space. Ensure that the machine you choose fits comfortably in your workshop without compromising on functionality.

2. Ease of Use

Look for a wood CNC machine that has a user-friendly interface and intuitive controls. The software should be easy to navigate, allowing you to create and modify designs effortlessly. Beginner-friendly features such as automatic tool calibration and material height adjustment can also simplify the learning process.

3. Cutting Area and Spindle Power

Consider the cutting area and spindle power of the wood CNC machine. The cutting area determines the maximum size of the workpiece you can handle, so choose a machine that suits your project requirements. The spindle power determines the cutting capabilities of the machine. For beginners, a machine with a lower spindle power can be sufficient, but keep in mind that higher spindle power allows for more versatility in cutting different types of wood.

4. Software Compatibility

Ensure that the wood CNC machine you choose is compatible with the software you plan to use. Most machines come with their own software, but it’s important to check if it supports popular design software such as AutoCAD or Fusion 360. Compatibility with your preferred software will make the design process seamless and efficient.

5. Budget

Consider your budget when choosing a wood CNC machine for beginners. While it’s tempting to go for the most advanced and feature-rich machine, it’s important to find a balance between your budget and the capabilities you require. There are plenty of affordable options available that still offer excellent performance for beginners.

How to choose the best CNC wood router kit?

- A ridge cutter is suitable for the processing of high-density wood composite board (plywood, particleboard, hard fiberboard, blockboard, etc.) or solid wood (softwood, hardwood, and modified wood).

- A double-edged straight groove milling cutter is suitable to process the multi-layer board and plywood.

- A diamond machining tool is recommended to process the Acrylic mirror sheet.

- A multi-strip milling cutter is perfect for the processing of rough machining particleboard.

- A single-edged spiral ball-end milling cutter is suitable for processing the cork, density board, native wood, PVC board, and acrylic large-scale deep relief.

- A single-blade special aluminum milling cutter is suitable for cutting Aluminum plates.

- A round bottom cutter is recommended to process the meticulous small relief works.

- A single-edged, double-edged up and down cutting cutter is perfect for the burr-free cutting process.

- A double-tool large chip evacuation spiral milling cutter is suitable to cut the MDF board.

- A single-edged spiral milling cutter is perfect for Acrylic cutting.

CNC Wood Router Applications

- Cabinets and Furniture.

- Sign Making and Carving

- Musical Instruments

- Plastic and Foam

- Marble and Stone Engraving

- Prototyping and 3D modeling

- Metal Fabrication and Steel Applications

- Exhibits and Scene / Prop Shops

- Architectural Millwork

- Aluminum and Brass Machining

How does a CNC wood router machine work?

Simply put, the 3 axis CNC wood carving machine works like a printer in terms of working principle.

The CNC router software (CAD) designs the engraving patterns and cutting paths to turn your ideas into electronic files. And the design and working path information is automatically transferred to the controller by the computer. Then the other type of CNC router software (CAM) turns the electronic files into G-codes. Such G-codes can drive the servo or stepper motor to work and control the CNC wood engraving machine spindle to move along the X, Y, and Z axes. So it can complete cutting, engraving, or carving work of multiple materials fixed on the working table.

Of course, sometimes, you have other machining requirements such as carving three-dimensional workpieces, curved surface machining of complex workpieces. To meet these demands, we also have CNC routers for woodworking with the rotating spindle, rotary device, automatic tool charge, or multiple spindles. You can choose one CNC wood cutting machine among them that can best suit your requirements.

IGOLDENCNC wood cnc machine in UK, US, Australia, Canada, India

IGOLDENCNC is a Chinese manufacturer of wood cnc machine that has gained popularity in the European and American markets. They offer a range of hobby and industrial CNC machines, including routers, engravers, and plasma cutters. IGOLDENCNC wood CNC machines are designed for small-scale projects and hobbyists. They are compact and affordable, making them suitable for home workshops, small businesses, and educational institutions.

You can find IGOLDENCNC twood cnc machine in the UK, US, Australia, Canada, from various retailers and online stores. It is advisable to do some research before making a purchase to ensure that the machine you choose meets your specific needs and budget.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.