A CNC programmer needs to determine the machining process by analyzing the part drawing, and write the CNC machining program accordingly. For a beginner to grow into a CNC programmer, he needs professional CNC knowledge, proficient use of G-code language, and proficient in various CAD/CAM programming software.

What Is CNC Programming

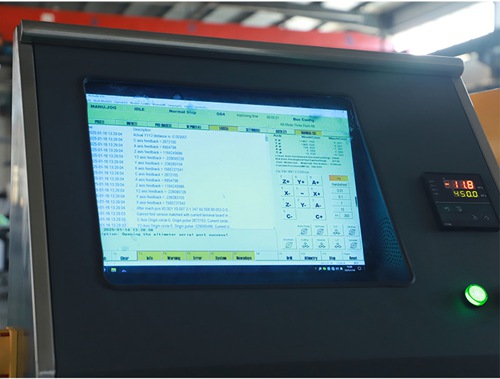

CNC program refers to the coded CAM software instructions to control the operation of a CNC Machine. It is a control program directly used for machining input from outside the CNC system, called CNC machining program.

In order to meet the needs of design, manufacture, maintenance and popularization, in terms of input codes, coordinate systems, machining instructions, auxiliary functions and program formats, two general standards have been formed internationally, namely the International Organization for Standardization (ISO) standard and the Electronic Industries Institute (EIA) standard.

CNC machining program is composed of various function words according to the specified format. Correctly understanding the meaning of each function word, properly using various function words, and writing programs according to the prescribed instructions are the keys to compiling programs.

CNC programmers must master the knowledge related to CNC machining, including the working principle, XYZ axis coordinate system, program structure and common CNC instructions.

What Is CNC Program

CNC programming refers to a process of automatically creating a CNC machining program with the assist of a computer, CAD drawing & designing software, and CAM modeling & manufacturing software to control a CNC machine to work.

CNC programming is one of the main contents in the preparation stage of CNC machining, which usually includes analyzing the part pattern, determining the machining process, calculating the tool path, obtaining the tool position data, creating the CNC machining program, making the control medium, proofreading the program and the part machining test.

How Many Types Of CNC Programming?

There are two most common types of CNC programming in the market, including manual programming and automatic programming.

Manual programming means that all stages of programming are done manually. Using general calculation tools, through various mathematical methods, the tool path calculation is performed manually, and the instructions are compiled. This method is relatively simple, easy to master for beginners, and has great adaptability. It is suitable for medium-complexity programs and parts programming with a small amount of calculation. It must be mastered by machine tool operators.

Manual Programming Steps

The manual programming steps include manually completing the CNC process of part processing, analyzing the part drawings, making process decisions, determining the processing route, selecting process parameters, calculating the coordinate data of the tool position, writing the CNC machining program list, verifying the program, and manual programming.

Pros

It is mainly used for point processing (such as drilling, reaming) or the processing of parts with simple geometric shapes (such as plane, square groove), the calculation amount is small, the number of program segments is limited, and the programming is intuitive and easy to implement.

Cons

For parts with free-form surfaces and complex cavities, the calculation of tool path data is quite cumbersome, the workload is large, it is extremely error-prone, and it is difficult to proofread, and some even cannot be completed at all.

What Is Automatic Programming?

Automatic programming refers to the use of a computer to write the source program of the part with the aid of a computer for parts with complex geometric shapes, and to generate a CNC machining program after processing.

Pros

With the development of numerical control technology, advanced numerical control system not only provides general preparatory functions and auxiliary functions for user programming, but also provides means for programming to expand numerical control functions. The parameter programming of the numerical control system is flexible in application and free in form. It has expressions, logical operations and similar program flows in high-level computer languages, which makes the machining program concise and easy to understand, and realizes functions that are difficult to achieve in ordinary programming.

Cons

CNC programming has its own language like computer programming, but the difference is that now the computer has developed to occupy the global market with Microsoft’s Windows as its absolute advantage. But the CNC machine has not developed to the level of mutual use, that is to say, their difference in hardware makes their CNC systems not compatible with each other for a while. Therefore, when machining a blank, it is first necessary to determine what type of system the machine uses.

How To Do CNC Programming?

CNC programming uses G-code language to describe the shape, process, parameters and auxiliary information of the part according to the rules, and then the computer automatically performs numerical calculation, tool center motion trajectory calculation, and post-processing to generate a part processing program list, and simulate the machining process. For parts with complex shapes, non-circular curve profiles, three-dimensional surfaces and other parts, the automatic programming method is efficient and reliable.

During the programming process, the CNC programmer can check whether the program is correct in time and modify it if necessary. Because the computer replaces the programmer to complete the tedious numerical calculation work and saves the workload of writing the program list, it can improve the programming efficiency by dozens or even hundreds of times, and solve the programming problems of many complex parts that cannot be solved by manual programming.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.