Natural stones are the first choice when anyone wants a material that is luxurious and durable at the same time. Among stones, there are many different materials, such as granite, marble, limestone, slate, and more.

In the world of precision cutting, the stone water jet cutting machine has emerged as a revolutionary tool. This technology has transformed the way we approach cutting tasks, offering unparalleled accuracy and efficiency.

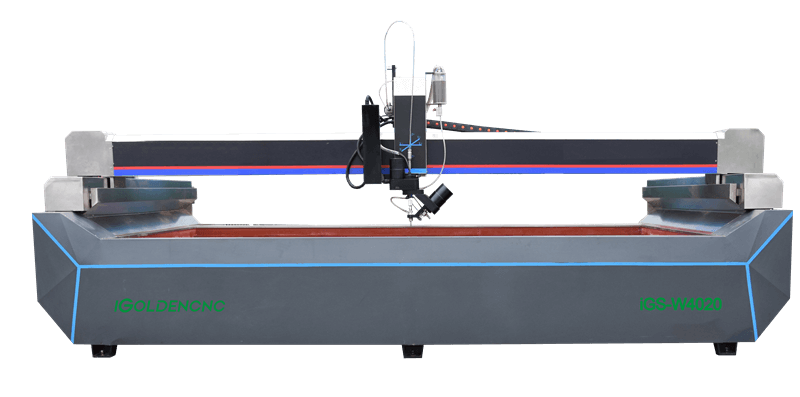

Stone Water Jet Cutting Machine

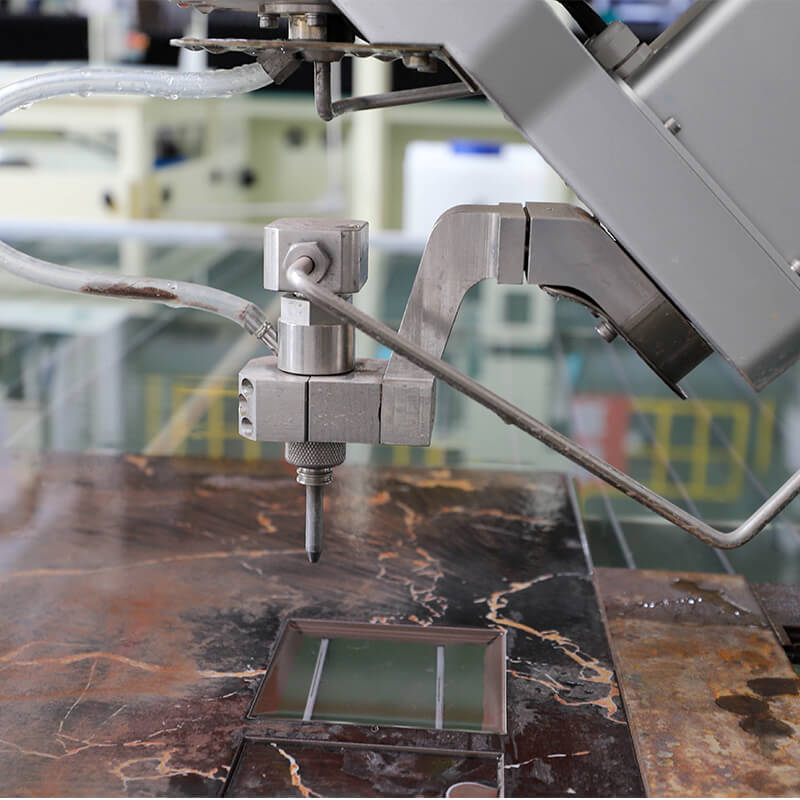

A stone water jet cutting machine is an advanced tool that uses a high-pressure stream of water, often mixed with abrasive particles, to cut through various materials, including stone. This method is renowned for its precision and ability to cut intricate shapes without compromising the integrity of the material.

Water-Jet Cutters have proven to be the most effective process for cutting and mitering a range of natural and engineered stones, eliminating safety issues caused by dust whilst being an efficient and cost-effective cutting process.

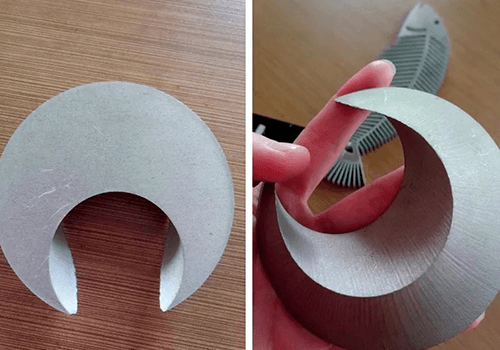

The 5 axis CNC water jet cutter machine adopts AC design, which can realize the x, y, z, a, c axis linkage, which greatly improves the cutting accuracy of the water jet cutting machine. This CNC water jet machine can be used on a three-axis platform Realize the plane and 3D cutting of the workpiece.Meanwhile this AC five-axis water jet glass cutting machine can easily solve the problems of arc plate cutting, cylindrical cutting, conical cutting, spiral blade cutting, etc. And after cutting, the cutting surface is neat and smooth, and will not damage the object being cut during the cutting process.

45 Degree Stone Cutting Machine

Benefits of Cutting Stone With a Water Jet Machine

Using a waterjet for stone cutting is better than traditional cutting tools. This is because of the several benefits that a waterjet cutter provides. Some of these benefits include:

Cold Cutting Process

Waterjet cutting is a cold cutting process, so it doesn’t cause heating of the cut area. Other cutting processes that use heat, such as laser cutting, create visible heat marks on the surface.

Heat stress also causes the material to lose its original strength and internal structure. The stone retains its original appearance in waterjet cutting – an immense benefit for stones like granite or marble.

Most stones have applications in aesthetic and decor projects. Therefore, the ability of a waterjet cutter to retain the original appearance of the stone being cut is a primary reason to use this method.

No Cracking

When cutting stones, cracking is a high risk that worries even professionals. Cracking during the cutting process can occur due to heat generation or due to the application of improper force.

In water jet cutting, there is neither heat nor any lateral force. The water beam is focused on little spots on the stone, eliminating the possibility of stone cracking and surface stress even at a high cutting speed.

Dust Free Cutting

One of the major issues while cutting stones is the dust generated in the process, especially with ceramic tile, granite, and marble. Dust can cause respiratory issues for workers close to where stone cutting is performed.

However, in water jet cutting, the stone particles removed from the workpiece get suspended in the water. Therefore, no dust particles are released into the air, leading to a cleaner and safer work environment.

Etching

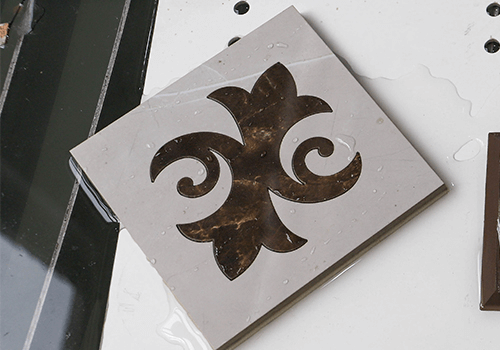

Waterjet cutting is not just capable of cutting stone but also etching the surface of the stone. In fact, waterjet CNC machines can produce automated etching of digital designs on any stone.

Etching works exceptionally well for materials like marble, glass, granite, limestone, and other materials. The depth of the etching produced by the water jet can be adjusted, leading to exceptional details and quality.

Eco-Friendly

All the water used in the water jet cutting process can be recycled back into the system. The dust captured in the water can also be collected and used as an abrasive when cutting other materials with a waterjet cutter.

This makes water jet cutting a very sustainable and eco-friendly process.

Versatile

Water jet cutting is a very versatile process. The machine has flexible tooling to cut different pieces of stone without making any changes to the machine setup.

The advantages of flexible tooling are that it reduces costs for labor and downtime required for changing tools.

Accurate

Water jet cutting has exceptional accuracy and produces minimal kerfs when cutting stone or any other material. Traditional cutting methods cannot achieve this kind of accuracy due to manual errors. The high accuracy is beneficial for applications like stone tiles, where a high degree of consistency is required.

FAQ

What materials can a stone water jet cutting machine cut?

A stone water jet cutting machine can cut a wide range of materials, including stone, metal, glass, rubber, and composites. Its versatility makes it suitable for various industries.

Is water jet cutting environmentally friendly?

Yes, water jet cutting is an environmentally friendly process. It does not produce harmful emissions or waste, and the water used can be recycled.

How precise is water jet cutting?

Water jet cutting is highly precise, capable of achieving tolerances as tight as 0.001 inches. This precision makes it ideal for intricate designs and detailed work.

What industries benefit from water jet cutting?

Industries such as construction, aerospace, automotive, and art and design benefit from water jet cutting due to its precision, versatility, and efficiency.

How does water jet cutting compare to laser cutting?

While both methods offer precision cutting, water jet cutting does not produce heat-affected zones, making it suitable for materials sensitive to heat. Additionally, water jet cutting can handle a wider range of materials, including reflective and non-metallic surfaces.

Conclusion

The stone water jet cutting machine is a powerful tool that has revolutionized the cutting industry. Its precision, versatility, and eco-friendly nature make it an invaluable asset across various sectors. By understanding the technology and applications of these machines, businesses can harness their full potential to achieve superior results.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.