The CNC granite stone cutting machine has revolutionized the stone fabrication industry by offering unparalleled precision, speed, and versatility. These machines use computer numerical control (CNC) technology to automate the cutting and shaping of granite and other types of stone, making it possible to create intricate designs and achieve high levels of accuracy.

Types of CNC Stone Granite Marble Cutting Machine

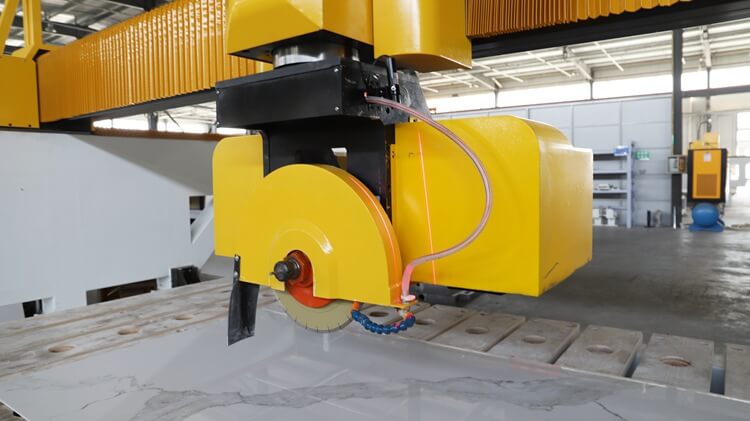

CNC Bridge Saws

CNC bridge saws are commonly used for cutting large slabs of granite and other types of stone. They feature a bridge-like structure that supports the cutting head, allowing for precise and controlled cuts.

A CNC bridge saw machine is a specialized cutting tool used in the stone fabrication industry. It features a bridge-like structure that supports the cutting head, which is guided by a computer program to perform precise and controlled cuts. The machine is equipped with a diamond blade that can cut through various types of stone, including granite, marble, and quartz. The automation provided by CNC technology ensures high precision and efficiency, making CNC bridge saw machines ideal for both small-scale and large-scale stone fabrication projects.

Intelligent five-axis bridge cutting machine is a comprehensive five-axis processing equipment. It has the function of taking photos, positioning and typesetting, automatic measurement of plate thickness and tool size, and the head can rotate 360 degrees. Cutting, edging, chamfering, digging and other multi-functional intelligent operating system, simple and easy to learn; High quality motor, high precision, fast speed; Transverse, longitudinal, arc, circular, arbitrary Angle, shape cutting. The machine head can move and rotate freely. Besides cutting modeling, it can also open material for large plate, 45 degree chamfering, open basin hole, stove hole, and slash line cutting.

Suitable for quartzite, rock plate, artificial stone, granite, marble all kinds of large and small stone decoration engineering stone processing machinery. Save plate save time save worry save effort!

- Advantages:

- High cutting precision

- Suitable for large slabs

- Automated cutting process

- Durable and robust design

- Applications:

- Countertops

- Flooring

- Wall cladding

- Architectural elements

5 Axis Bridge Cutting Saw Parameter

| Technical indicators | parameter |

| Model | iGS-B3320(Pro) |

| Stroke of X axis | 3300mm |

| Stroke of Y axis | 2000mm |

| Z-axis stroke 1 | 255mm(Blade Diameter 400mm) |

| A axis | 90° |

| C axis | 360° |

| Saw blade motor power | 7.5kw/11kw / 15kw/18.5kw |

| Blade Diameter | 350mm/400mm/450mm |

| Motor power | XYZ axis 1.8kw (Z-axis holding brake); A-axis 0.85kw; C axis 1.3kw |

| Input power | 3-phase AC 380V/220V 50-60Hz 10A |

Standard configuration function: Laser positioning, table flip, cutter, can cut square, round, horse belly side cutting, 45 degree cutting, Taichung basin cutting, Yin Angle drilling and milling, milling cutter opening.

Optional Functions:Suction cup displacement, photo layout, inverter, transformer, clean installation and measurement software.

5 Axis Bridge Cutting Machine Advantage

- 1. The A axis can automatically rotate 0-90°, while the C axis can rotate up to 360°.

- 2. It is equipped with a high-precision on-board camera, which brings higher-definition images and can provide high-precision stone processing. Moreover, it can take pictures to position stone plates, and can automatically plan the cutting path directly from the generated map, which greatly improves the processing efficiency.

- 3. The overturned worktable is adopted, which has large overturning weight redundancy, up to 80°.

- 4. Adopts a 11kw motor with high precision, it can complete circular cutting, square cutting, sector cutting, oval cutting, 45 miter cutting, drilling, external edge polishing, etc.

- 5. The robotic system has a lift capacity of 75 kgs for stone slab moving.

- 6. The 5-axis cutting head can miter and interpolate in any direction.

CNC Water Jet Cutters

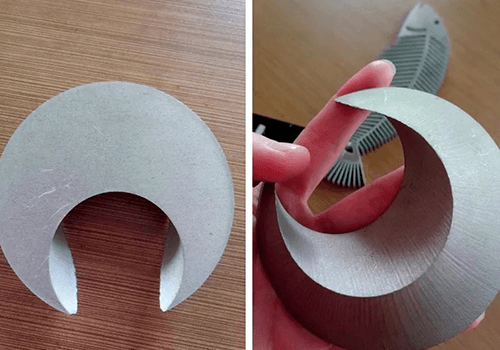

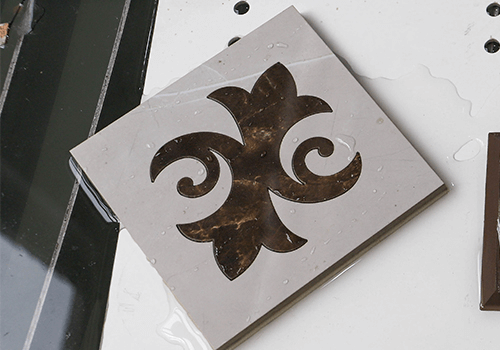

CNC water jet cutters use a high-pressure stream of water mixed with abrasive particles to cut through granite and other stones. This method is ideal for creating intricate and detailed cuts without generating heat.

High pressure water cutting system mainly includes pressurization system, cutting platform, sand storage system, control system and auxiliary system.

Water cutting cutting without thermal deformation, to avoid the physical and chemical changes of materials, widely adapted to the cutting and processing of various materials, has the reputation of “universal cutting machine”, the incision is smooth and flat without burr, generally no need to reprocessing, the equipment is controlled by numerical control system, high cutting precision, cutting joint less than 1.2mm, easy to cut, save materials, The process does not produce environmentally polluting waste;

Numerical control water knife for those other methods are difficult to cut materials such as aramid, titanium alloy and a variety of composite materials is very ideal processing means.

- Advantages:

- High cutting precision

- No heat generation

- Suitable for intricate designs

- Versatile cutting capabilities

- Applications:

- Decorative stonework

- Inlays

- Custom shapes

- Artistic designs

Water Jet Cutting Machine Parameter

| Model | iGWJ-4020 |

| Platform size | 4200*2200mm |

| Cutting stroke | 4000*2000*150mm |

| A axis rotation Angle | ±60° |

| C axis rotation Angle | Infinite rotation |

| Max. cutting speed | 20m/min |

| Max. running speed | 50m/min |

| Cutting accuracy | ±0.1mm |

| Rotating accuracy | ±0.1° |

| Control accuracy | ±0.05mm |

| Repeated positioning accuracy | ±0.05mm |

| Platform | Steel platform |

| CNC garnet feeder | Taiwan FLOW sype |

| Motor servo | Japan Yaskawa servo motor |

| Guide rail | Taiwan HIWIN |

| Screw | Taiwan HIWIN |

| Gear rack | Imported rack and pinion from Switzerland |

| Control system | WEIHONG |

| Electrical element | Schneider |

High pressure water cutting system mainly includes pressurization system, cutting platform, sand storage system, control system and auxiliary system.

Advanced Performance

- Gantry design lathe bed, solid and stable, with a higher strength;

- X/Y/Z axis adopts the new labyrinth protection to prevent double professional waterproof protection;

- X/Y axis adopt high quality LINDEN, Sweden and Taiwan silver guide rail, heavy support, guarantee the parts machining precision, stable and durable, Z axis fully enclosed design of lifting mechanism of backwash in the cutting process of sand and water erosion can’t lead screw and guide rail;

- Adopt Japanese valley centralized lubrication system, make the equipment maintenance automation;

- Internal components choose schneider international brand, quality, reliable operation;

- Use dimensional macro WEIHONG water cutting control system for special purpose, simple easy to operate;

- International famous brands and yaskawa servo motor, reliable quality, long service life.

Stone CNC Routers

Stone CNC routers are versatile machines that can cut, shape, and engrave granite and other stones. They use a rotating cutting tool to perform various operations, making them suitable for both cutting and engraving.

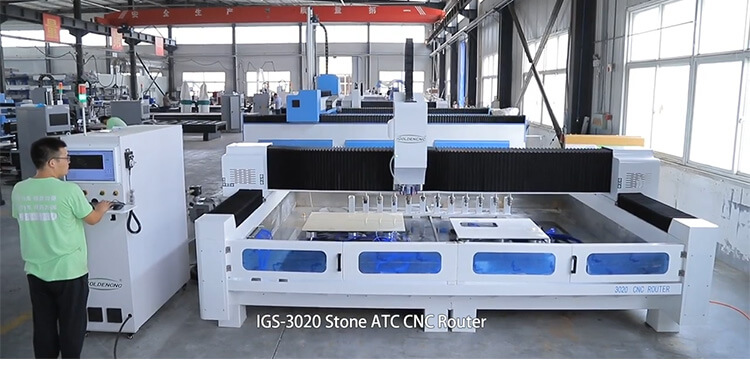

ATC Stone CNC Machining Center

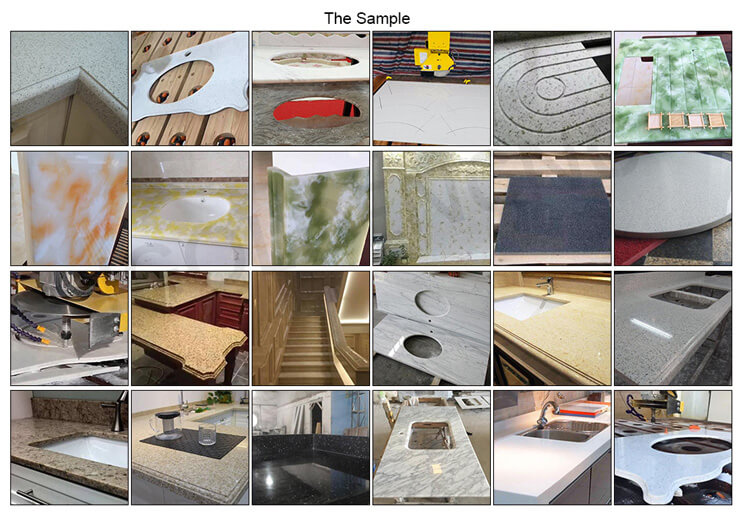

Stone processing center is a CNC automatic engraving high-tech equipment, mainly used for the processing of stone countertop, can achieve a feeding to complete all the processes of countertop processing. Stone countertop copying, special-shaped processing, grinding Roman edge, treatment of circular arc after retaining water, cutting basin holes, grinding basin along, polishing and other processes can also do stone relief carving.

Widely used in kitchen countertops, bathroom countertops, stone tabletop, coffee table countertop, TV counter surface processing, can also be used in billiard table, welcome table countertop, ordering table and other stone countertops.

Quartz Stone CNC Processing Center Applications

Technical Data

| X, Y Axis Working Area | 2000*3000mm |

| Z Axis Working Height | 500mm |

| Positioning Accuracy | 0.05mm |

| Re-positioning Accuracy | 0.02mm |

| Body Structure | Welding Body |

| X, Y Axis Structure | Gear Rack |

| Z Axis Structure | Screw |

| Max. Running Speed | 20000mm/min |

| Max. Working Speed | 10000mm/min |

| Spindle | 5.5kwWater-cooling |

| Spindle RPM | 24000 |

| Working Voltage | AC 380V±10%

/50-60Hz |

| Machine Weight | 3300kg |

If you need more detailed information, please inform us as soon as possible.

CNC Stone Cutting Advantage

- The whole high quality steel is welded and tempered to ensure the long-term use of the machine without deformation;

- The larger storage of automatic tool changing system makes the whole process from opening, cutting, milling molding and polishing all kinds of processes in one go, fully realize a high degree of automation;

- Intelligent environmental protection, the whole process of automatic environmental protection processing; Create a dust-free workshop to reject pneumoconiosis;

- Positioning adsorption block, double-sided sealed suction system combined with high-power adsorption pump + auxiliary positioning device effectively increase the adsorption capacity of the sucker, to ensure that the stone does not shift during processing.

- Electric oil injection system, machine maintenance more time and labor saving;

- The machine comes with circulating water tank, the whole machine realizes self-circulation, only need to change the water regularly to clean.

- With Japan Pantoscopicguide rail and rack, high positioning accuracy, smooth sliding, reliable quality, long life.

- Professional CNC control system, easy to learn and easy to operate.

- Applications:

- Engraved stone plaques

- Custom stone shapes

- Decorative elements

- Signage

Benefits of CNC Granite Stone Cutting Machines

High Precision and Quality

CNC granite stone cutting machines offer exceptional precision and quality, allowing for the creation of detailed and intricate cuts. The computer-controlled movements ensure minimal distortion and high accuracy, resulting in high-quality stone products.

Speed and Efficiency

CNC machines are known for their speed and efficiency, making them suitable for high-volume production. The automated cutting process reduces the overall production time, increasing productivity and reducing costs.

Versatility

CNC granite stone cutting machines are versatile and can be used on various types of stone, including granite, marble, and quartz. This versatility makes them suitable for a wide range of applications in the stone fabrication industry.

Durability and Robustness

CNC machines are equipped with durable and robust components that can withstand the rigors of stone cutting. This durability ensures a long lifespan and reliable performance, making them a valuable investment for stone fabricators.

Automation and Reduced Labor

The automation of CNC machines reduces the need for manual labor, increasing efficiency and reducing the risk of human error. This automation also allows for the production of complex and intricate designs that would be difficult to achieve manually.

CNC Stone Cutting FAQ

1. What types of stone can be cut using CNC stone cutting machines?

CNC granite stone cutting machines can be used to cut various types of stone, including granite, marble, quartz, and other natural and engineered stones.

2. How does CNC cutting compare to traditional stone cutting methods?

CNC cutting offers higher precision, speed, and efficiency compared to traditional stone cutting methods. The automation of CNC machines reduces the need for manual labor and increases the accuracy of cuts.

3. What industries benefit the most from CNC marble stone cutting machines?

Industries such as countertop fabrication, flooring and wall cladding, architecture, decorative stonework, and signage benefit greatly from the precision, speed, and versatility of CNC marble stone cutting machines.

4. Are there any limitations to CNC granite cutting machines?

While CNC granite cutting machines offer many advantages, they may not be suitable for all applications. Factors such as stone type, thickness, and cost should be considered when choosing a cutting method.

5. What maintenance is required for CNC granite cutting machines?

Regular maintenance, including cleaning and inspecting the cutting tools, checking the alignment, and monitoring the machine’s performance, is essential for ensuring the optimal performance of CNC granite cutting machines.

Conclusion

CNC granite stone cutting machines offer exceptional precision, speed, and versatility, making them an ideal choice for various stone fabrication applications. Whether you are involved in the production of countertops, flooring, architectural elements, decorative stonework, or engraved plaques, a CNC granite stone cutting machine can enhance the quality and efficiency of your projects. By understanding the different types of CNC machines and their benefits, you can make an informed decision and choose the right machine for your needs.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.