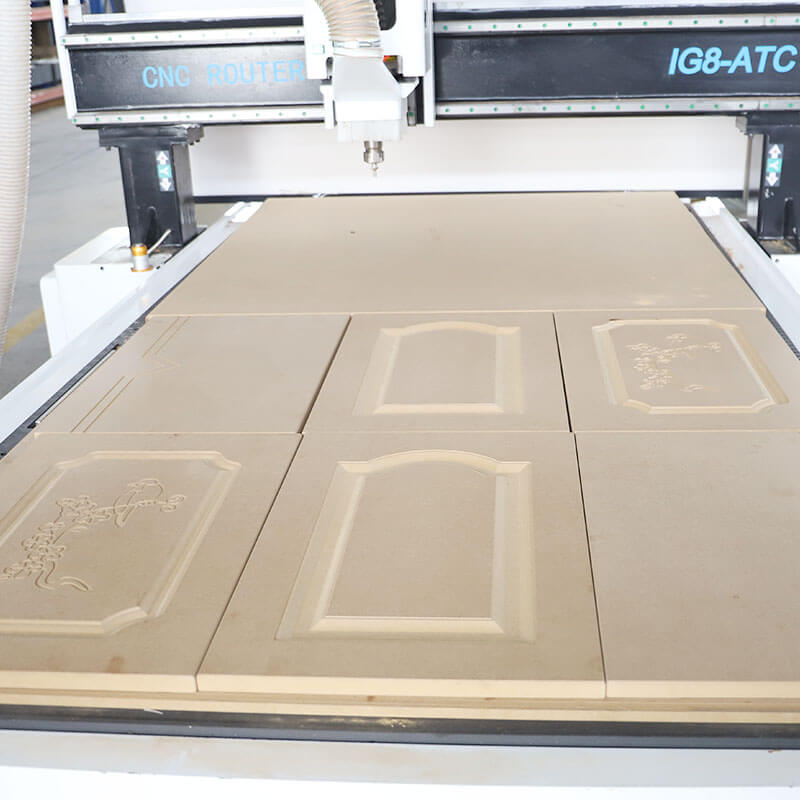

This machine is a ATC CNC router machines,And this automatic wood carving machine is all steel construction, which can provide the rigid foundation required for ultra-smooth routing results.The ATC CNC Router machine comes standard with the 9KW(12HP) automatic tool changer with 8-position tool rack,So this machine has fast processing speed and high processing quality.This woodworking carving machine can process wood,Mdf,plywood,acrylic,soft metal and so on.

Automatic Wood Carving Machine

This woodworking carving machine has Hybrid Vacuum and T-slot table, so we can quickly fix the workpiece. This ATC CNC router machines are powered by hybrid servo drive motors and controlled by an easy-to-use and learn handheld controller (DSP-Controller).

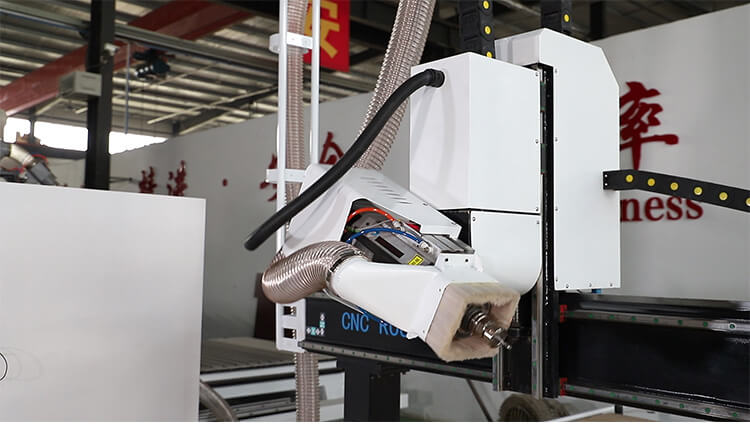

Automatic Tool Changer Function Of This Woodworking Carving Machine

This machine is a professional ATC CNC router machines, it has a 9kw high-frequency automatic tool change spindle and an 8-position tool rack behind the machine. We can put different tools on the rack and perform various types of processing on the workpiece . This not only increases the processing speed of the machine but also improves the processing quality.

High-Quality Machine Parts

The woodworking carving machine has many high-quality machine parts, such as the Fuling Inverter, Hiwin Square Rail and Shimpo gear reducer. The Fuling Inverter is intended for control of drives where high accuracy of speed regulation and a wide range of control are required. They provide achievement of the maximum moment on the shaft of the spindle and the possibility of direct control of this moment.

The Japan Shimpo gear reducer are with high precision, and it can increase torque, therefore make the motor more powerful. And The machine adopts Taiwan Hiwin square rail, which is more than twice durable. And the use of high quality helical rack pinion, makes it high precision .

Hybrid Vacuum And T-Slot Table

The work table of the woodworking carving machine is the Hybrid Vacuum and T-slot table. This table is made of very hard PVC, this material is very stable, and has strict tolerances for precision cutting, it can be your plate And machine parts provide a very stable and robust processing platform. The surface of the vacuum table is multi-zoned, which allows the operator to easily switch from whole piece processing to smaller part processing (which requires a smaller segmented area). The area can be easily closed by the control valve on the front of the machine. The gasket can also be wired to adapt to various material sizes and styles. The APS series machines also include a heavy-duty aluminum T-slot profile at multiple locations on the table surface. This T-slot can accommodate Alpha’s square M6 T-nuts. So you can use two ways to fix the material.

Automatic wood carving machines offer several advantages over traditional hand carving methods. They provide greater precision, consistency, and speed, allowing for complex designs and mass production. They can also replicate designs accurately, making it easier to create multiple identical pieces. These machines are commonly used in various woodworking applications, including furniture production, decorative carving, sign making, and architectural woodworking.

They are suitable for carving both softwoods and hardwoods, offering versatility in material choices. It’s important to note that different automatic wood carving machines may have varying features, capabilities, and cutting technologies. Some machines may also offer additional functionalities such as 3D carving or multi-axis movement, enabling even more intricate and creative wood carvings.

9KW High Frequency Automatic Tool Changer Spindle

This is the 9kw HQD high frequency automatic tool changer spindle, this kind of spindle is of high quality and can work for a long time. It uses high-quality ER collets and ISO 30 tool holders. The Fully programmable speeds from 6000 to 24000 RPM, and it comes complete with pneumatically retractable vacuum hood. So this spindle has a long service life and low failure rate.

DSP Controller

This is the DSP hand controller,it is very easy to operate and learn,and it does not require additional connection to the computer, which makes the machine completely autonomous.This controller support multiple cylinders, and linear tool change.The Emergency stop button can easily stop the machine.And the Tool path Supported: .g/*.nc/*.u??/*.demo/*.iso/*.eng/*.cut/*.dxf/*.plt/*. txt.This controller has a large storage space and high compatibility. Compared with computers, it has higher reliability and stability.

Software Language: Chinese, English, Polish, Vietnamese

Hybrid Servo Motor System

This is the servo motor,it has Closed-loop control technology, which like the AC servo system does not lose step. The position encoder is installed so that the motor has closed-loop characteristics of the servo motor, which fundamentally solves the problem of lost motion of the conventional stepping motor. It can improve the performance of the motor, and the effective torque of the motor can be increased by more than 30%. And this motor system can effectively reduce the motor heating. The output current of the drive becomes larger and smaller as the load and speed increase.

This motor don’t need for gain adjustment, it is very convenient to use. The hybrid servo system not only has the convenience of using a stepper motor, but also has the reliability of a servo system. It can be used very conveniently, without tedious parameter adjustment.

Applications of 5×10 Wood CNC Router

1. Woodworking industry: Three dimensional wave plate processing,cupboard doors, wooden doors, window processing, video game cabinets and panels, computer table and furniture auxiliary processing.

2. Advertising industry: Advertising signs, logo production, acrylic cutting, plastic molding, a variety of materials advertising decorative products production.

3. Die Industry: You can engrave copper, aluminum, iron and other metal molds, and artificial marble, sand, plastic plates, PVC pipe, wood and other non-metallic mold.

4. Other industries: You can carve all kinds of large relief, shadow carving, widely used in craft gift industry.

What is an ATC CNC router?

ATC CNC router machine is an intelligent CNC automatic tool changer tool kit with automatic tool changing spindle. It is widely used in many industries, such as carpentry woodworking, stone carving, foam engraving cutting, mold manufacturing and metal fabrication. The tool magazine can carry 4-20 pieces of different tools. When working, CNC tools can be automatically replaced according to work requirements, without manual operation, and greatly improve work efficiency. There are two types of CNC ATC kits, including linear Automatic Tool Changer CNC and disk Automatic Tool Changer CNC.

Why choose ATC CNC Machine?

1).ATC CNC router generally adopts high-power CNC Router Tool Changer spindle, and the most commonly used ones are 9kw and 12KW spindle. The high-power spindle has fast startup and high torque, which can give full play to the advantages of high speed and high efficiency of high-power tool change spindle.

2).ATC CNC router generally adopts high torque servo motor made in Japan and is equipped with reducer with high reduction ratio. This makes CNC router with tool changer machining center have the advantages of low noise, high speed and high positioning accuracy.

3).Equipped with a unique tool changing device, the required tools can be changed at will, and the special tool setting table can accurately compensate the tool length error. The tool change time of the cnc automatic tool changer is only a few seconds. The standard tool magazine comes with 8 tools, which can customize the tool magazine with larger capacity.

Type of tool changer

The tool magazine and the automatic tool change device make up the The automatic tool change system of the CNC machining center. The cnc automatic tool changer system has two major advantages: one is that it only retains one spindle, which is conducive to simplify the structure of the spindle and improve the spindle’s rigidity; the other is that a large number of different types of tools and functions can be stored in the library, which facilitates the completion of various complex and multi-step machining processes. So, whether there is an automatic tool change system is an important sign to distinguish between manual tool change CNC machine tools and CNC machining centers.

There are 3 types of Automatic tool changer: direct tool change, manipulator tool change method and turret head, and in the next, we will introduce the three types of CNC Router Tool Changer for you one by one.

(1).Direct Tool Change type

The direct tool change means the tool change is completed by the tool magazine and the spindle box. Like the name says, this is a direct tool change type.

According to whether the tool magazine moves when tool changes, the direct tool change has two types: the tool magazine moving type and the tool magazine fixed type. In the tool magazine moving mode, the tool magazine can be moved. Before the tool changing, the tool magazine moved to the tool change working zone, and exits the zone after the tool is changed. This kind of tool change type is more movement in the tool magazine, tool changes speed is faster, and the the layout is more particular, but it is also has disadvantage, such as the poor flexibility and adaptability.

In the tool magazine fixed type, the tool selection is mainly performed by the movement of the gantry. The tool magazine can be static, or it can only rotate in position. The former one can only perform sequential tool selection, which is suitable for CNC automatic tool changer with a small number of tools, such as 8 tools, while the latter can realize tool selection by indexing. This tool selection method reduces the movement of the tool magazine, can greatly simplify the design structure of the tool magazine, and the control of the tool change process is simple and reliable.

(2).Automatic Tool Change type

Automatic tool change type is a widely used tool change method, which is composed of tool selection system, tool magazine,tool exchange mechanism and other parts. Compared with other tool change method, this kind of CNC tool change structure is more complicated. It transfers the tool between the tool magazine and the spindle, and pushes the tool to the spindle, then sends the replaced tool back to the tool magazine inside.Although this CNC tool change method is not as simple as the previous one, it prevents the tool magazine and spindle from moving due to tool change and is replaced by an CNC Router Tool Changer. In this way, the range of motion of mechanical parts is reduced, the tool change can be completed faster, and the design layout is more flexible, so it has been widely used in most CNC Router Tool Changer Machine.

(3).Turret head type

The turret head is another tool change method, which moves the required tool to the corresponding position by rotating the brick tower. Usually it is a sequential tool change, so it has the advantages many advantages, such as the compact structure and extremely fast tool change speed. It is usually used for machining the workpieces that need complete multiple processes such as crankshafts and some other slender workpieces.

The turret head automatic tool change is divided into two types: turret tool post tool change type and brick tower spindle head tool change. The tool change method of the turret tool post is to install the annular tool post on the turret spindle. Different tools are arranged in sequence on the tool holder. Through the rotation of the turret head, automatic tool change action is realized. The position of the tool depends on the rotation of the tool holder. Index to position. This is the simplest CNC Router Tool Changer with good structural rigidity and can withstand the cutting force of rough machining. This kind of CNC Router Tool Changer has higher requirements on the positioning accuracy of the rotation of the tool post. If there is an error in the positioning accuracy of the rotation, the tool cannot be sent to the exact position.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.