A 3D wood CNC router machine is a type of computer-controlled milling machine designed specifically for woodworking tasks in three dimensions. It utilizes a computer numerical control (CNC) system to precisely carve, cut, and shape wood materials, enabling the creation of intricate and detailed three-dimensional designs.

4 Axis Wood CNC Router Machine 1325

The primary feature of a 3D wood CNC router is its ability to carve and shape three-dimensional objects from wood.It can handle complex designs, intricate details, and sculptural elements in wood.

Key Features 3D Wood CNC Router Machine

- 3D Capability: Unlike traditional CNC routers that operate in two dimensions (X and Y axes), a 3D wood CNC router machine adds a Z-axis movement. This allows for the creation of complex three-dimensional shapes, contours, and reliefs in wood.

- Precision and Accuracy: The CNC system controls the movement of the machine with high precision, resulting in accurate and consistent cuts, carvings, and engravings. This level of precision is particularly beneficial for intricate designs and fine detailing.

- Versatility: A 3D wood CNC router machine can handle a wide range of woodworking tasks. It is suitable for cutting, carving, engraving, milling, and shaping various types of wood, including softwoods, hardwoods, MDF, plywood, and more. It can also work with other materials like plastics and composites.

- Design Flexibility: With 3D modeling software and a 3D wood CNC router machine, you have the freedom to create and produce complex, customized designs. It allows you to bring your creative ideas to life and produce intricate patterns, sculptural elements, and textured surfaces in wood.

- Time and Labor Savings: The automation provided by the CNC system significantly reduces the time and labor required for woodworking tasks. Once the design is programmed, the machine can work continuously and consistently without the need for manual intervention, resulting in increased productivity and efficiency.

- Reproducibility and Consistency: A 3D wood CNC router machine can accurately replicate designs, ensuring consistent results across multiple workpieces. This is particularly advantageous for production runs or when creating matching components for furniture, cabinetry, or other woodworking projects.

- User-Friendly Interface: Modern 3D wood CNC router machines often come with user-friendly interfaces and software that make it easier to program designs, set cutting parameters, and control the machine’s operation. This allows both experienced users and beginners to operate the machine effectively.

3D Wood CNC Router Machine Details

| Model | iGW-3AR-1325 |

| Structure | Seamless steel welded |

| Table | Vacuum table with t slot |

| XYZ working size | 1300*2500*200mm |

| XYZ transmission | XY axis is helical rack and gear,Z axis Ball Screw |

| XYZ guide rail | Taiwan Hiwin Line 20mm Square guide |

| Spindle | 6kw italy HSD air cooling spindle |

| Spindle collet | 2 pieces |

| Inverter | Well known china Fuling 7.5kw |

| Motor | Servo motor(Yaskawa 850w) |

| Driver | Servo driver(Yaskawa 850w) |

| Controller system | DSP A18 control system |

| Voltage | 220/380v, 3phase 50HZ |

| Packing weight | 1500KG |

Applications of the CNC Wood Router Machine

Wood CNC engraving machines are widely used in the furniture industry, furniture decoration industry, woodworking decoration industry, the musical instrument industry, wooden crafts industry, etc. This machine is suitable for large-area board carving, solid wood furniture carving, solid wood mural carving, MDF carving, and cutting, etc.

Furniture Industry: large-area panel carving, solid wood furniture carving, solid wood art font carving, solid wood carving, MDF paint-free door carving, kitchen window, and door carving.

Mold Industry: it can engrave various molds, wooden molds, aviation wooden molds, propellers, automobile foam molds, etc.

Advertising Industry: acrylic, two-color board, PVC, ABS board, aluminum-plastic board engraving and cutting, various signs, badges, seat signs, bronze medals, fonts, fonts, various signs, trademarks, and other materials. Handicraft Industry: gifts, decorations, wooden toys, metal reliefs, and copper and aluminum fonts.

Musical Instrument industry: carving patterns and patterns. Packaging Industry: cutting and processing of plastic, wood, etc.

Optional Device for Wood CNC Router

1,Wood Duo Aggregate The woodworking duo aggregates designed for the Wood Line electro spindles allow a wide range of machining operations to be carried out, including milling, boring and cutting.

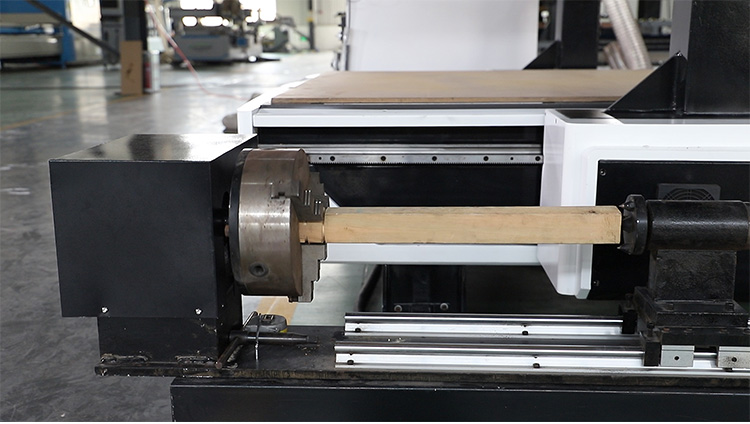

2, Rotary Axis (The 4th Axis of CNC Router / 4 Axis CNC Router) The application of the Rotary Axis CNC Router is cylindrical or 3D sculptures in stone, woodworking, advertising, metal, and other industries. We can build the Rotary Axis CNC Router. At the same time, the rotary shaft device can also be added on the standard CNC Router to realize the cylindrical engraving working. Thus, round material and flat material can be processed in one CNC Router. It will save a lot of time and improve high efficiency.

3, Safety Laser Curtain / laser barriers to Proect Operator We suggest installing laser barriers to create laser safe temporary work areas. It is designed to enable operators to work in complete safety. When you need maximum flexibility for enclosing a laser work area or need a temporary Class 1 laser safe work zone, choose movable laser barriers. Movable barriers are a great alternative to laser curtain systems.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.