In the realm of modern manufacturing and crafting, the CNC router machine has emerged as a game-changer. These machines, particularly the small CNC router machines, offer unparalleled precision, versatility, and efficiency for a wide range of applications. Whether you’re a hobbyist, a small business owner, or an industrial manufacturer, a small CNC router machine can significantly enhance your production capabilities.

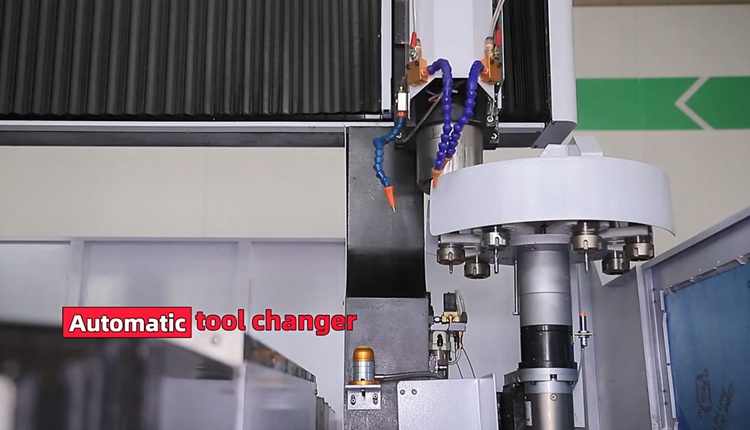

Small CNC router machine with automatic tool changer

A small CNC (Computer Numerical Control) router machine is a compact, computer-controlled device designed to cut, carve, and engrave various materials with high precision. Unlike traditional manual routers, CNC routers use computer software to control the movement and operation of the cutting tool, allowing for intricate and consistent designs.

Hobby CNC with tool changer

Hobby CNC router with tool changer offer exceptional precision, speed, and versatility, making them an ideal choice for various applications. Whether you are involved in woodworking, sign making, prototyping, jewelry making, or education, a small CNC router machine can enhance the quality and efficiency of your projects. By understanding the features, benefits, and applications of these machines, you can make an informed decision and choose the right small CNC router machine for your needs.

Applications of Small CNC Router with Automatic Tool Changer

In the woodworking industry, the small cnc router is a valuable tool for creating intricate designs and ensuring consistent quality. Applications include:

Applications Projects:

- Sign-making: These routers are also popular in the sign-making industry for creating custom signs with intricate designs and lettering.

- Plastic fabrication: With the right tools and bits, a 4×4 CNC wood router can be used to cut and shape plastic materials for various applications.

- Prototyping: CNC wood routers are often used in the prototyping process to create precise and accurate models or prototypes of wood products.

- Artistic projects: Artists and craftsmen use 4×4 CNC wood routers to create intricate wood carvings, sculptures, and other artistic pieces

- Woodworking: Cabinetry, furniture, signage, architectural elements.

- Plastics and Composites: Prototyping, mold making, custom parts.

- Foam and Soft Materials: Cutting shapes for packaging, exhibits, models.

- Light Metalworking: Aluminum parts, nameplates, decorative elements.

How to Choose Samll CNC router

- Machine Frame and Construction: Look for a CNC wood router with a sturdy and rigid frame construction to minimize vibrations and ensure accurate cutting. A robust frame helps maintain stability and precision during the cutting process.

- Spindle Power: Consider the power of the spindle, which is the motor that rotates the cutting tool. Higher spindle power allows for faster cutting speeds and the ability to work with harder wood materials.

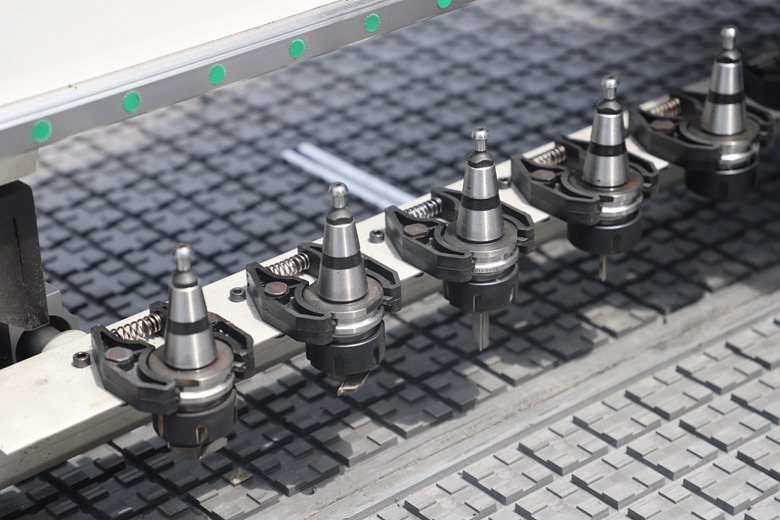

- Cutting Tools: small cnc router machine with automatic tool changer use various cutting tools, such as router bits, to perform different operations like cutting, carving, and engraving. Ensure that the machine’s spindle collet size matches the cutting tools you plan to use, and check for tool compatibility with the router’s tool holder or automatic tool changer (if applicable).

- Control System and Software: The CNC wood router should have a reliable control system that provides user-friendly operation and accurate control over the cutting process. Look for compatibility with popular CAD/CAM software, as this allows you to import designs and generate toolpaths for the machine.

- Bed Surface and Hold-Down Mechanism: The router bed should have a flat and durable surface to support the workpiece. A vacuum table or clamping system is often used to secure the wood material during cutting to prevent movement or vibrations.

- Dust Collection: Woodworking generates a significant amount of dust, so having a dust collection system integrated into the small cnc router machine with automatic tool changer is beneficial. This helps maintain a clean working environment, extend the life of cutting tools, and ensure operator safety.

Benefits of Small CNC Router Machines

High Precision and Consistency

Small CNC router machines offer exceptional precision and consistency, allowing for the creation of detailed and intricate designs. The computer-controlled movements ensure minimal error and high accuracy, resulting in high-quality products.

Efficiency and Speed

CNC routing is a fast and efficient process, capable of producing high-quality products in a fraction of the time required by traditional methods. This increased speed translates to reduced project times and lower labor costs.

Versatility

Small CNC router machines are versatile and can work on a variety of materials, including wood, plastic, metal, and foam. This versatility makes them suitable for a wide range of applications, from woodworking to metalworking.

Automation and Reduced Labor

The automation of CNC routers reduces the need for manual labor, increasing efficiency and reducing the risk of human error. This automation also allows for the production of complex and intricate designs that would be difficult to achieve manually.

Compact and Space-Saving

The compact size of small CNC router machines makes them ideal for small workshops and limited spaces. They offer the same precision and capabilities as larger machines but in a more space-efficient package.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.