Woodworking CNC machine tools and cabinet production solutions in modern cabinet manufacturing is becoming an industry development trend. Through the combination of digital process planning, automated processing, intelligent scheduling and management, and personalized customization, it can not only improve production efficiency, reduce costs, improve product quality, and meet customers’ personalized needs, but also promote the intelligence and intelligentization of the industry. Efficient and personalized development. Therefore, for cabinet manufacturing companies, the introduction of advanced woodworking CNC machine tools and cabinet production solutions will help enhance the company’s core competitiveness and achieve sustainable development.

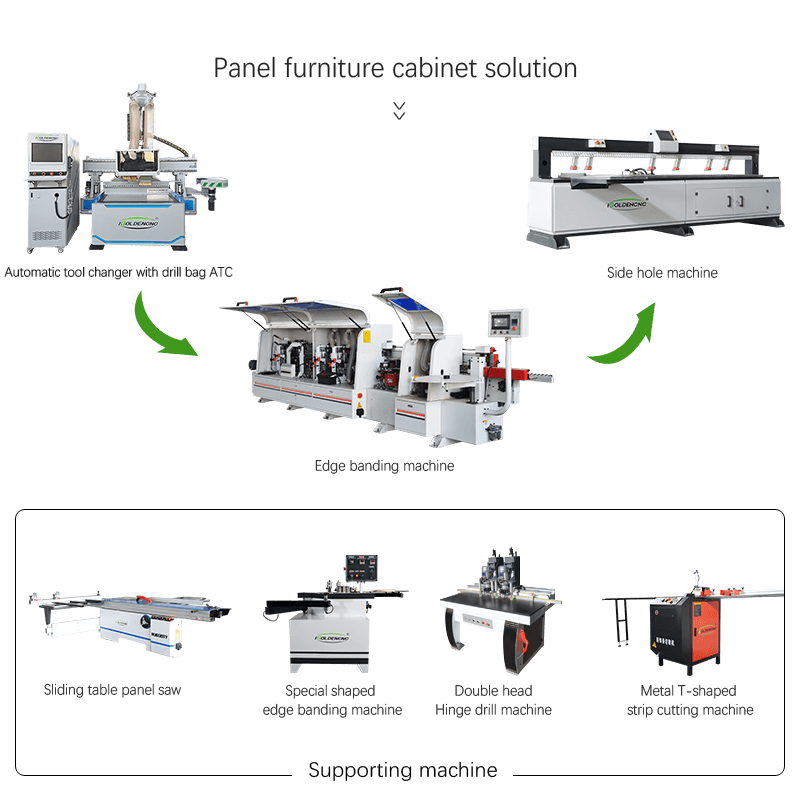

Panel furniture and cabinet production line

The panel furniture and cabinet production line is mainly composed of CNC cutting machine, laser side hole machine and automatic edge banding machine. It can be used for processing and manufacturing cabinets such as panel furniture, cabinets, wardrobes, panel furniture and children’s furniture.

CNC woodworking beam panel saw machine,The electronic cutting saw has a wide range of uses. Because of its high rotation speed, the electronic cutting saw preprograms the size of the board to be cut, realizes automatic feeding, improves the production efficiency, and improves the work efficiency by 3 – 4 times compared with the ordinary board cutting machine.

Processing Material: Plexiglass, light guide plate, circuit board, large core board, MDF board, wood-based board, artificial stone, aluminum-plastic board, MDF board, MDF, flower board, ABS board, PVC board, PS board, PET board, Grating plate, artificial leather, synthetic stone, solid wood and other materials are used. It can also be used to cut hardboards such as gypsum board and laminate flooring.

Automatic Edge Banding Machine

Compared with other common automatic edge banding machines, this side hole drilling edge banding machine can also synchronously drill holes. Besides that this edge banding machine also can realize the pre-milling, gluing, end cutting, rough and fine trimming, tracking chamfering, scraping, edge banding and polishing.

Automatic Six Side CNC Drilling Machine

This is a high-end CNC drilling machine for panel furniture, which has the advantages of high processing efficiency and high degree of automation. it can realize six-side position processing and front and back groove processing at a time.

Linear ATC CNC Machining

This linear ATC CNC cutting machine adopts double-station processing, which greatly improve the efficiency. Two working platform can realize automatic loading and unloading operation, no idle time, and it can increase capacity by 30%-40%.

Wood Brush Sanding and Polishing Machine for Cabinet Door

It is suitable for the rough and fine sanding, polishing and polishing of solid wood, density board, iron sheet and other materials such as linear and L-shaped wood lines and door panels, heterogeneous surfaces, flat surfaces and curved surfaces. It is ideal equipment for producing heterosexual polishing of doors, windows, cabinets and furniture.

The combination of woodworking CNC machine tools and cabinet production solutions

In modern cabinet manufacturing, the combination of woodworking CNC machines and cabinet production solutions allows for more efficient customized production. The specific performance is as follows:

- Digital process planning: By introducing advanced digital process planning software, woodworking CNC machine tools can accurately plan and optimize the processing path based on the design drawings of the cabinets, thereby improving processing efficiency and quality.

- Automated processing: Using the automated processing function of woodworking CNC machine tools, rapid and precise manufacturing of cabinet parts can be achieved, providing strong guarantee for subsequent assembly and customized production.

- Intelligent scheduling and management: Through the intelligent scheduling and management system in the cabinet production solution, the linkage and collaborative operation of woodworking CNC machine tools and other production equipment can be realized, the production process can be optimized, and the overall production efficiency can be improved.

- Personalized customization: With the high-precision processing capabilities of woodworking CNC machine tools and the customized production system of cabinet production solutions, full personalized customization from design to manufacturing can be achieved to meet the diverse needs of customers.

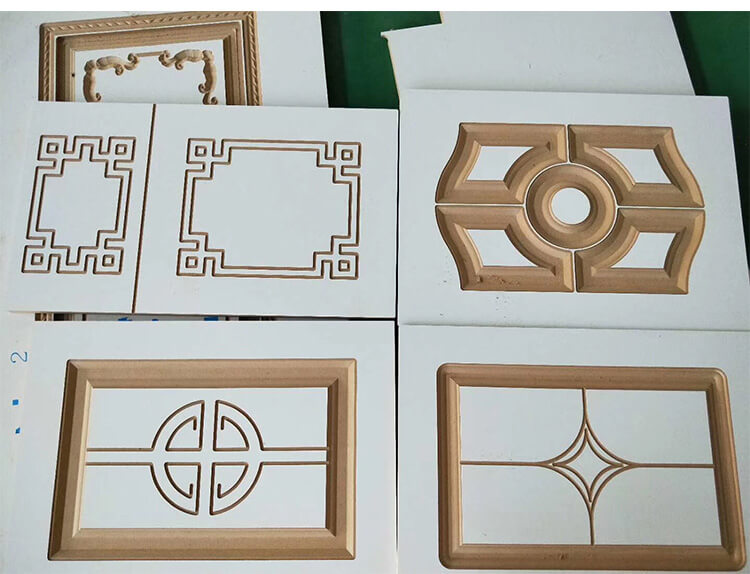

Application of woodworking CNC machine tools in wood processing

Woodworking CNC machine tool is a kind of CNC equipment specially used for wood processing, which has the characteristics of high precision, high efficiency and high automation. In the wood processing process, woodworking CNC machine tools can complete various complex cutting, drilling, engraving and other tasks, and can ensure extremely high processing accuracy and consistency.

In cabinet production, the application of woodworking CNC machine tools has the following advantages:

- Improve production efficiency: Woodworking CNC machine tools can continuously and efficiently complete wood cutting, drilling and other processing, greatly improving production efficiency.

- Reduce labor intensity: Woodworking CNC machine tools have a high degree of automation. Operators only need to input processing parameters to complete complex wood processing tasks, reducing workers’ labor intensity.

- Improve product quality: The high processing precision of woodworking CNC machine tools can ensure the quality and consistency of cabinet products.

Application of cabinet production solutions in customized production

The cabinet production solution is a management and technical solution specifically for cabinet production, aiming to improve production efficiency, reduce costs, improve product quality and meet customers’ individual needs. In cabinet production, the application of cabinet production solutions has the following advantages:

- Improve production efficiency: By using advanced production management software and automation equipment, cabinet manufacturing companies can optimize the production process and improve production efficiency.

- Reduce costs: The cost control system in the cabinet production solution can help companies achieve refined management and reduce waste and cost expenditures.

- Improve product quality: The quality control system in the cabinet production solution can help companies achieve strict quality control and improve product quality and consistency.

- Meet individual needs: By introducing advanced customized production systems and technologies, cabinet manufacturing companies can meet the diverse needs of customers and improve customer satisfaction.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.