Small CNC router, desktop CNC router, home CNC router, Mini CNC router with other ordinary CNC router machines, this hobby CNC machine has a relatively small size. And it’s mainly including 600×900 mm and 1200×1200 mm. This type of small CNC machine has a compact structure and a small footprint. Therefore, it is easy to move and use. And this hobby CNC router adopts advanced industrial numerical control operation software and typesetting processing software to complete various processing requirements on the small workpiece of users. Therefore, the hobby CNC router is popular among woodworking enthusiasts and in the advertising industry.

Small Shop CNC router 1200*1200*250mm

A hobby CNC router is a mini machine tool kit for hobbyists in home shop and small business. It cuts the parts through the tool path generated by the CAD/CAM software working with the computer and the designed patterns. A hobby CNC machine usually runs with a DSP controller, as well as a user friendly computer numerical controlled system. It has better software compatibility with ArtCAM, CastMate, Type3, UG and other 2D/3D design software.

Small CNC Router Parameter

Choosing a CNC router for a small shop and beginners involves considering factors such as size, ease of use, affordability, and functionality. Assess the available space in your shop and consider the size of the CNC router that will fit comfortably. Compact or benchtop models are often suitable for small shops, as they have a smaller footprint and can be easily moved or stored when not in use.

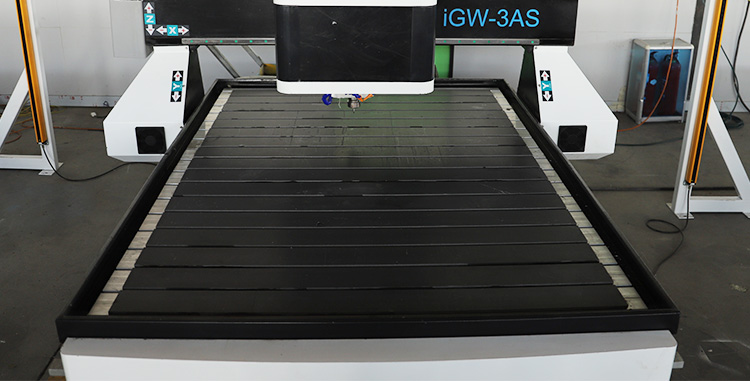

| Model | iGW-3AS |

| Working area | 1200*1200*250mm |

| Spindle | 9KW automatic tool changer spindle |

| Inverter | Fuling |

| Driver | Servo Drive and Servo Motor |

| Control System | DSP A11 |

| Table | Aluminum table + sink |

| Oil lubrication | Manual oiling |

| Oil mist system | Yes |

| Transmission | XY axis helical rack Z axis Taiwan ball screw |

| Rail | X, Y, Z axis Taiwan HIWIN 20 Square guide rail |

| Bed | Thick steel welded big square tube |

| Gangry | Strong frame |

| Cabinet | Independent cabinet |

| Voltage | 3 phase/380V |

| light curtain | Three sets of light screen, protection height of 1120mm, size 40 * 50 * 1188mm |

CNC Router for Beginners

Consider the size of the cutting area (X, Y, and Z axes) and ensure it can accommodate the maximum dimensions of the workpieces you plan to work with. Additionally, check the machine’s compatibility with the materials you intend to cut, such as wood, plastics, or soft metals.

Applications

Hobby CNC routers are commonly used in small business, small shop, home business, home shop, craftsman, hobbyist, advertising, woodworking, signs, logos, letters, numbers, arts, crafts, building models, emblem, badge, display panels, furniture, and decorations.

Woodworking

Wooden door and furniture, windows, tables, chairs, cabinets, panels, 3D wave plate, MDF, computer desk, musical instruments.

Advertising

Billboard, logo, sign, 3D characters cutting, acrylic cutting, LED/Neon channel, literal-hole cut, lightbox mold, stamp, mould.

Die Industry

Copper sculpture, aluminum engrave, metal molds, plastic sheeting, PVC.

Decorations

Acrylic, density board, artificial stone, organic glass, soft metals like aluminum and copper.

Here are some recommendations:

Size and Workspace: Assess the available space in your shop and consider the size of the CNC router that will fit comfortably. Compact or benchtop models are often suitable for small shops, as they have a smaller footprint and can be easily moved or stored when not in use.

Ease of Use and Software: Look for a CNC router that comes with user-friendly software or has compatibility with popular CAD/CAM programs. This will make it easier for beginners to design projects, generate tool paths, and operate the machine. Some CNC routers may include their own software, while others may require separate software purchases.

Construction and Durability: Choose a CNC router with a sturdy and durable construction that can withstand regular use. Look for components made from quality materials, such as steel or aluminum, and check customer reviews or ratings for reliability.

Cutting Area and Workpiece Compatibility: Consider the size of the cutting area (X, Y, and Z axes) and ensure it can accommodate the maximum dimensions of the workpieces you plan to work with.

Spindle Power and Speed: The spindle power and speed affect the cutting capabilities and efficiency of the CNC router. For small-scale projects, a lower to mid-range spindle power (around 1-3 HP) should be sufficient. Adjustable spindle speeds allow for versatility in working with different materials and cutting tools.

Workholding Options: Look for a CNC router that offers various workholding options, such as clamps, vacuum tables, or t-slot beds.

Support and Training: Consider the level of support and training provided by the manufacturer or supplier. As a beginner, you may benefit from comprehensive documentation, tutorials, and responsive customer support to help you get started and troubleshoot any issues.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.