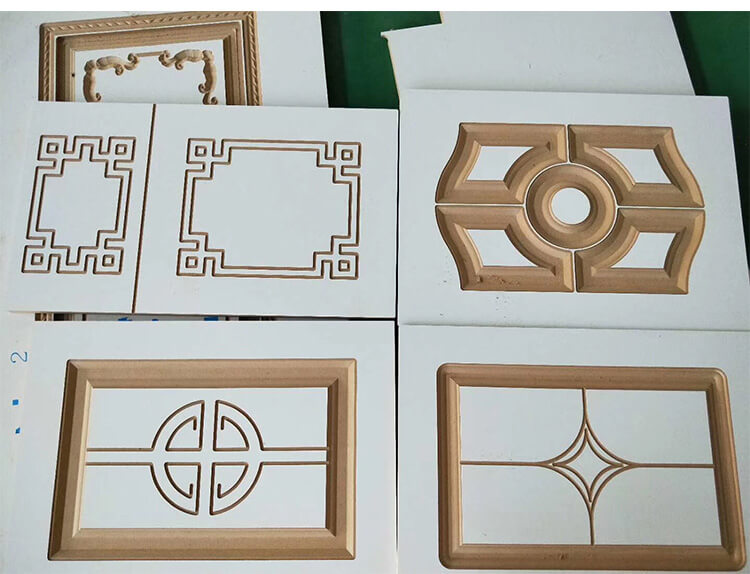

The best row type atc woodworking cnc router embossing production engraving software designs the engraving path, and then enters it into the computer for automatic engraving, so the details of the engraving are neat and unified. Whether it is a flower plate or a cloud bead, each place has the same size, and it does not look any different , The machine is suitable for mass production, making furniture manufacturing more refined and perfect.

Woodworking CNC Machines with ATC

Best row type atc woodworking cnc router are mainly composed of three parts: computer, control system, and engraving machine body. The CNC wood engraver uses the special engraving software configured in the computer for design and layout. And then the computer automatically transmits the design and layout information to the control system of the wood etching machine.

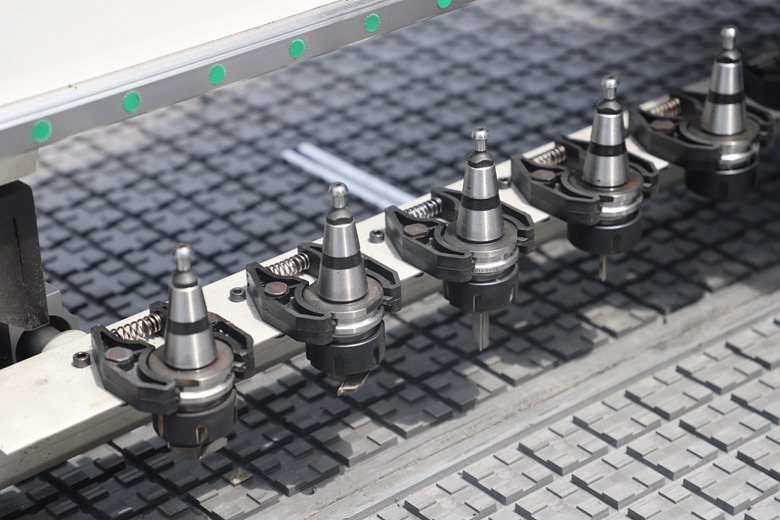

ATC CNC router with tool changer is suitable for the processing of various complex products or a variety of processing. It can be equipped with 6, 8, 10, 12 tools according to the different production process requirements of customers. This CNC machine is ideal for light to heavy-duty manufacturing, such as 3D foam, signage, wood, stone, and metalworking.

ATC CNC Router With Tool Changer Features

1. The bed body steel structure is welded with thick-walled square tubes, and is subjected to vibration aging treatment. It is durable and does not deform

2. Z-axis adopts Taiwan TBI ball screw, Taiwan high-precision Hiwin linear guide, high precision and more durable.

3. 8 Pcs Linear automatic tools changer, fast speed changer tools, high efficiency for woodworking.

4. Weihong system with break point specific memory, power outages continued carving, processing time forecast etc.

5. Vacuum table with double layer hard PVC,it has big suction and will not deform for a long time.

Atc CNC Router With Tool Changer Applications

1. Woodworking Industry: Stereo wave board processing, wooden door, cabinet making and other furniture production.

2. Advertising Industry: Label making, PVC plate, PCB board (drilling and engraving), double color boards, logo production, acrylic cutting, plastic suction for making advertising dedication, word cutting, sign making, crystal word, LED display screen, doorplate, nameplate, etc.

3. Mold Industry: Wood mold, foam mold and metal mold, etc.

4. Musical instrument industry: Instrument 3D surface carving, shape cutting

5. Woodcrafts.

6. Exhibition industry: Showcase.

7、Other Industry make building models, wood mold, air wooden mold, propeller, automotive foam mold. Shaping three-dimensional surfaces such as violin, erhu musical instruments and so on.

Woodworking CNC Machines with ATC

1. best row type atc woodworking cnc router is mainly used for wood processing, crystal, copper, aluminum, etc. Make it more beautiful.

best row type atc woodworking cnc router s have a wide variety and many brands, resulting in uneven prices.

It belongs to wood processing machinery.

It is divided into three control modes: first, all operations are controlled by the computer. When the engraving machine is working, the computer is in working state and cannot carry out other typesetting work, which may cause waste products due to misoperation of the computer;

Second, it adopts the control of single chip microcomputer, which can typeset while the engraving machine works, but can not turn off the computer, which can reduce the waste products caused by computer misoperation;

Third, the USB port is used to transmit data. The system has a memory capacity of more than 32m. After saving the file, you can completely leave the computer, turn off the computer or carry out other typesetting, which can greatly improve the work efficiency.

The best row type atc woodworking cnc router embossing production engraving software designs the engraving path, and then enters it into the computer for automatic engraving, so the details of the engraving are neat and unified. Whether it is a flower plate or a cloud bead, each place has the same size, and it does not look any different , The machine is suitable for mass production, making furniture manufacturing more refined and perfect.

Compared with hand-carving, the processing efficiency and precision of woodworking engraving are unmatched by hand-carving. Some people will choose woodworking engraving machine to engrave and then use manual modification, which can make the engraving efficiency and precision higher.

Compared with hand-carving, woodworking engraving machine embossing has the same depth, the transition point is smoother, the depth of hand-carving is different, and the carving depth is also limited.

It is undeniable that the embossing production of woodworking engraving machine will make the mahogany furniture market trend and prompt the mahogany furniture industry to adapt to survival quickly.

Conclusion

A woodworking CNC machine with ATC is an invaluable asset for any woodworking operation. Its ability to automate tool changes, combined with high precision and versatility, makes it a powerful tool for a wide range of applications. By considering factors such as material compatibility, tool capacity, software integration, and budget, you can select the right CNC machine with ATC for your needs. Proper maintenance and safety measures are essential to ensure the efficient and safe operation of these advanced machines.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.