In the woodworking industry, precision, efficiency, and versatility are crucial for producing high-quality products. Traditional woodworking methods, while effective, often require significant manual labor and time. However, with the advent of CNC wood milling and cutting machines, the landscape of woodworking has dramatically changed.

CNC Wood Milling & Cutting Machine

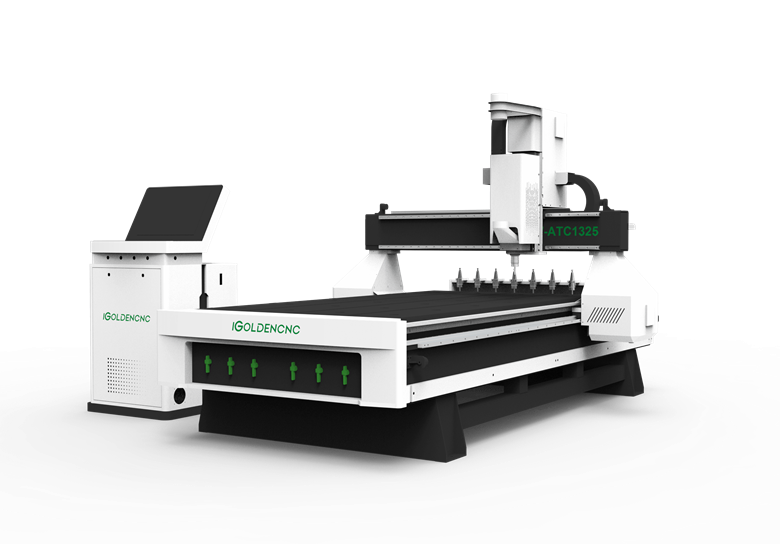

ATC CNC Router

A CNC wood milling and cutting machine is a computer-controlled device that automates the process of cutting, shaping, and milling wood. Whether you’re crafting furniture, cabinetry, or decorative wood pieces, CNC machines provide the precision and consistency needed for professional results. In this comprehensive guide, we will explore the functionality, benefits, and applications of CNC wood milling and cutting machines, along with tips for selecting the right machine for your workshop.

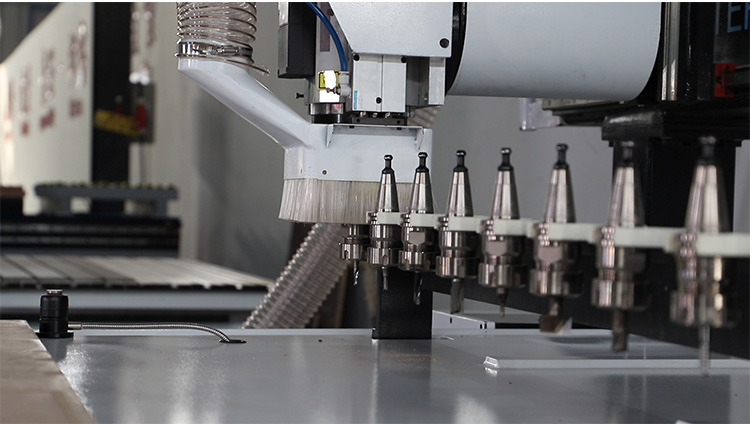

ATC CNC router is the first choice for enterprises with large production volume. It can automatically change the required tools by computer program control without stopping work during processing. And it can complete cutting, hollowing, grooving, punching, milling grooves, milling planes and other different processing.

CNC Wood Carving Machine

A CNC wood router is an automatic machine tool for wood cutting, relief carving, drilling & slotting, which works with 2D/3D designed files by CAD/CAM software. A CNC wood router machine is composed of bed frames, spindles, T-slot table or vacuum table, vacuum pump, CNC controller, motor driver, guide rail, rack and pinion, ball screw, power supply, limit switch, collets, tools & bits, and other parts & accessories. The most common types of wood routers include 3 axis, 4th axis, 4 axis, 5 axis CNC woodworking machines.

An industrial CNC router table is made of strong welded tubular steel, which is heavy duty and stable with high accuracy during machining. A gantry type industrial CNC machine has powerful functions and multiple applications in one machine, whether furniture making or aluminum cutting, all can be easily completed.

Hobby CNC Wood Milling & Cutting Machine

If you’ve ever enjoyed your time creating an awesome wood craft with a small CNC machine, investing in a hobby CNC router could be for you. In addition to arts and crafts, hobby CNCs can make customized signs, logos, gifts, molds, models, and even PCBs.

For those of you looking to start your own business, it’s a very lucrative side business or full-time operation. It’s an attractive option for both starters and professionals. Other than its surprising profitability, a small CNC is pretty versatile. It can be a great DIY tool, a low startup-cost business, or a worth trying way to expand your commercial manufacturing.

CNC Wood Milling & Cutting Machine Applications

CNC wood routers are commonly used in small business, small shop, home business, home shop, craftsman, hobbyist, advertising, woodworking, signs, logos, letters, numbers, arts, crafts, building models, emblem, badge, display panels, furniture, and decorations.

Woodworking

Wooden door and furniture, windows, tables, chairs, cabinets, panels, 3D wave plate, MDF, computer desk, musical instruments.

Advertising

Billboard, logo, sign, 3D characters cutting, acrylic cutting, LED/Neon channel, literal-hole cut, lightbox mold, stamp, mould.

Die Industry

Copper sculpture, aluminum engrave, metal molds, plastic sheeting, PVC.

Decorations

Acrylic, density board, artificial stone, organic glass, soft metals like aluminum and copper.

What is a CNC Wood Milling & Cutting Machine?

A CNC (Computer Numerical Control) wood milling and cutting machine is a type of automated machine that uses a computer to control the movement of a cutting tool (such as a router bit or milling cutter) to perform various operations on wood. These machines are capable of cutting, drilling, engraving, and milling wood with extreme precision, following a pre-programmed design or pattern.

Unlike traditional woodworking tools, which require manual guidance, CNC machines automate the entire process, allowing for more complex designs and faster production times. The machine operates on three primary axes—X, Y, and Z—allowing it to move the cutting tool in multiple directions to create detailed and intricate shapes.

How Does a CNC Wood Milling & Cutting Machine Work?

The operation of a CNC wood milling and cutting machine begins with the creation of a design or pattern in a CAD (Computer-Aided Design) software. This design is then converted into G-code, a language that the CNC machine understands. The G-code contains instructions that tell the machine how to move the cutting tool along the X, Y, and Z axes to create the desired shape.

Once the design is loaded into the machine, the operator places the wood on the machine’s worktable and secures it in place. The CNC machine then follows the G-code instructions to cut, mill, or engrave the wood with high precision. The entire process is automated, reducing the need for manual intervention and ensuring consistent results.

Components of a CNC Wood Milling & Cutting Machine

1. Spindle

The spindle is the part of the machine that holds the cutting tool and rotates at high speeds to perform the cutting or milling operations. The power and speed of the spindle are critical for achieving clean and precise cuts.

- Capabilities: High-speed rotation for cutting, milling, and engraving wood.

- Advantages: Provides the necessary power to cut through various types of wood with precision.

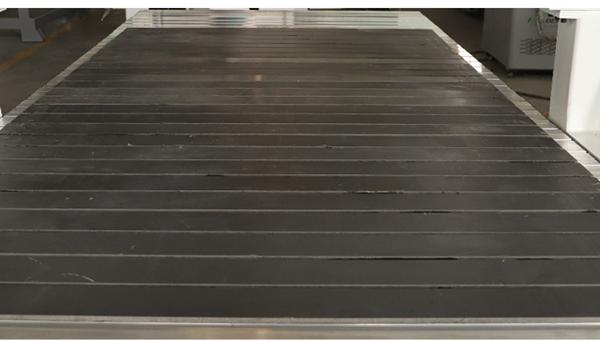

2. Worktable

The worktable is where the wood is placed during the cutting or milling process. It is typically made of a durable material like aluminum or MDF (Medium-Density Fiberboard) and may feature a vacuum system to hold the wood securely in place.

- Capabilities: Supports the wood during cutting and ensures stability.

- Advantages: Provides a flat, stable surface for accurate cutting and milling operations.

3. CNC Control System

The CNC control system is the brain of the machine, allowing the operator to input specific cutting parameters such as dimensions, patterns, and tool paths. The CNC system ensures that each cut is performed with high precision and consistency.

- Capabilities: Allows for precise programming of cutting and milling operations.

- Advantages: High precision, automation, and the ability to handle complex cutting sequences.

4. Cutting Tools (Router Bits, End Mills)

The cutting tools used in a CNC wood milling and cutting machine include router bits, end mills, and other specialized tools designed for different types of cuts. These tools come in various shapes and sizes, each suited for a specific type of operation, such as straight cuts, grooves, or decorative edges.

- Capabilities: Cuts, mills, and engraves wood with precision.

- Advantages: Versatile, with a wide range of tool types for different cutting and milling tasks.

5. Dust Collection System

A dust collection system is an essential component of a CNC wood milling and cutting machine. It helps to remove sawdust and debris from the cutting area, keeping the workspace clean and improving the machine’s performance.

- Capabilities: Removes sawdust and debris from the cutting area.

- Advantages: Keeps the workspace clean and improves cutting accuracy.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.