Portable Edge Banding Machines

Enter the Portable Edge Banding Machine, a versatile tool that has revolutionized the way craftsmen and small businesses approach edge finishing.

A Portable Edge Banding Machine is a compact, mobile tool designed to apply edge banding materials to the edges of furniture components. Unlike stationary machines, portable models offer flexibility and convenience, allowing users to perform edge banding tasks on-site or in small workshops.

The use of solid round bar guide rails and silicone conveyor belts improves motor life and does not damage the board. The double-speed governor design makes the operation more convenient, smooth and burr-free, and the double-row wheel function is added. The narrow plate has no pressure, high-speed edge sealing, and stable performance.Portable edge banding machines streamline the edge finishing process, reducing the time and effort required. This efficiency allows you to complete projects faster and take on more work.

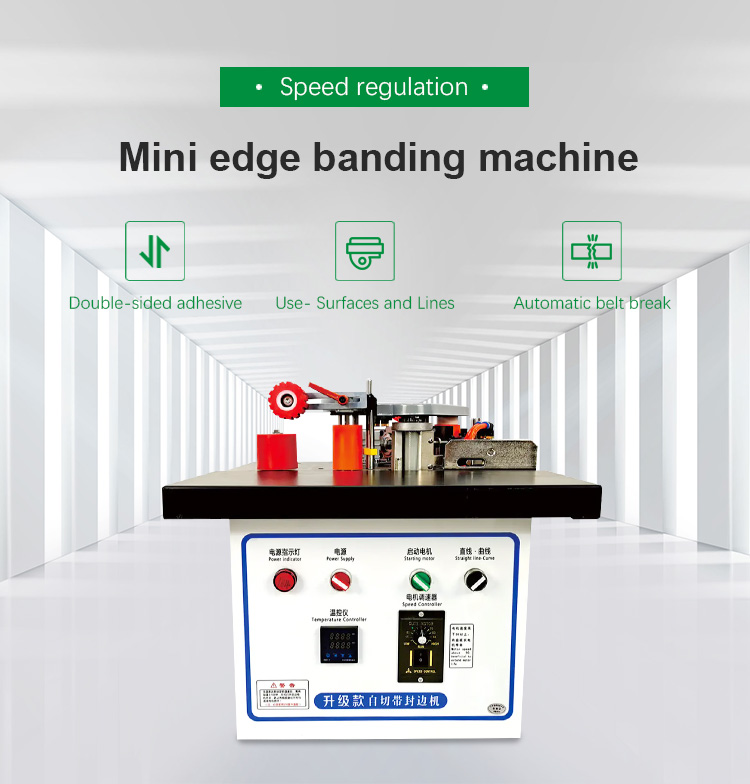

Portable Edge Banding Machine

The weight of the mini edge banding machine is about 22KG. It is small in size and easy to carry. The edge banding speed can be adjusted freely. It can be equipped with a large platform supporting device. , Large glue pot, independent switch easy to operate, saving time and effort.

| Edge sealing method | Straight and curved |

| Voltage | 220V |

| Rated power | 1200W |

| Heating time | 5-10min |

| Edge width | 6-60mm |

| Belt break method | Automatic belt break |

| Glue volume | 1000ml |

| Dimension | 500*500*470mm |

| Weight | 22KG |

Small Edge Banding Machine Technical Parameters

| Function | Glue edge sealing – trimming |

| Voltage | 220V |

| Power | 2300W |

| Heating time | 5-10min |

| Edge width | 10-50mm |

| Trimming height | 10-50mm |

| Belt break method | Automatic belt break |

| Glue capacity | 1000ml |

| Gluing method | Double-sided adhesive |

| Size | 850*460*400mm |

| Weight | 34KG |

Portable Edge Bander Banding Machine

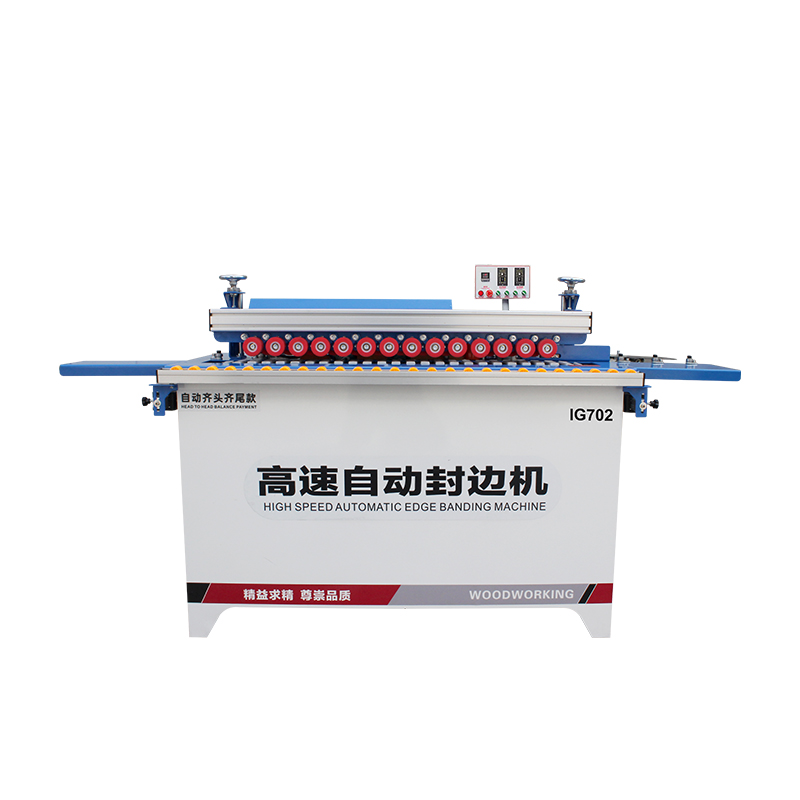

One-piece aluminum profile pressure beam is convenient for sealing large plates and continuous edge sealing, silicone conveyor belt, two solid round bar guide rails, edge sealing speed 0-6m/min, automatic head and tail, built-in dust collector, curved and straight.

| Function | Automatic feeding – Gluing – Trimming – End cutting – Polishing |

| Voltage | 220V |

| Power | 4000W |

| Weight | 75KG |

| Dimension | 1280*470*690mm |

| Edge width | 8-50mm |

| Heating time | 5-10min |

| Edge banding speed | 0-6m/min |

| Belt break method | Automatic belt break |

| Edge sealing method | Straight and curved |

| The narrowest edge is 5cm (to be customized), the default delivery is the narrowest 6cm | |

| Standard widening, lengthening, base, vacuuming | |

Small Edge Banding Machine Technical Parameters

The use of solid round bar guide rails and silicone conveyor belts improves motor life and does not damage the board. The double-speed governor design makes the operation more convenient, smooth and burr-free, and the double-row wheel function is added. The narrow plate has no pressure, high-speed edge sealing, and stable performance。

| Function | Automatic feeding – Gluing – Trimming – End cutting- Scraping — Polishing |

| Voltage | 220V |

| Power | 3000W |

| Weight | 240KG |

| Dimension | 1750*870*1120mm |

| Edge band width | 0-50mm |

| Edge band thickness | 0.3-3mm |

| Edge Banding Type | Straight edge banding,The narrowest edge is 10cm |

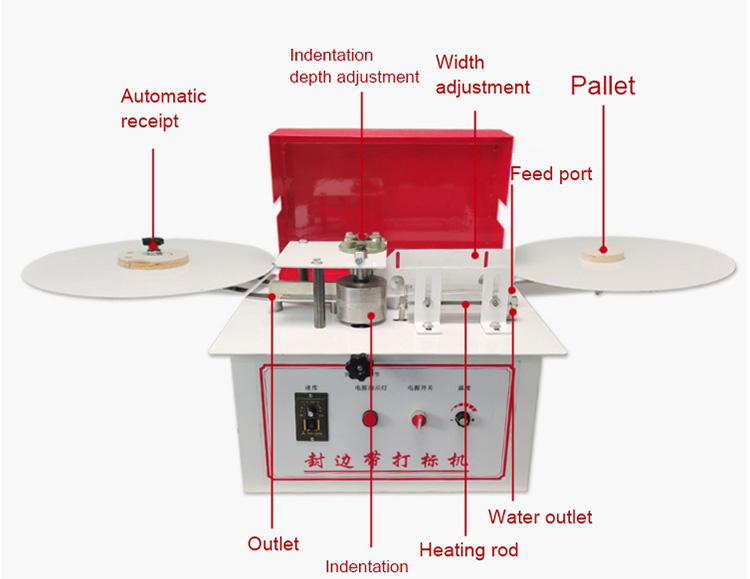

Portable Edge Bander Banding Machine

This kind of special-shaped edge banding machine for small shops does not have to worry about insufficient glue supply and glue glue problem of the glue tank edge banding machine. The gluing layer adopts a plate-type quick positioning design to achieve ultra-thin edge banding.

1. With the timing break function, it can realize flexible switching between feeding and cutting.

2. Equipped with suction cups, it has the advantages of strong bearing capacity and strong stability.

3. Adopting intuitive digital display operation panel, it is easy to operate.

4. Edge banding materials include PVC, veneer, melamine, plastic and other materials.

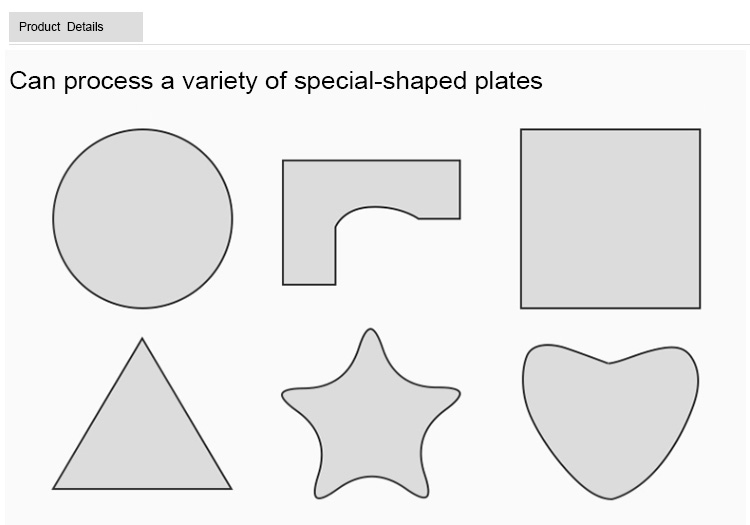

Edge Banding Machine for Small Shops

Edge banding machines are mainly used for banding the edges of various panel furniture. For instance, cabinets, wardrobes, shelves, custom furniture, office furniture, tables, chairs, windows, doors, cupboards, and other wood products.

Reviews