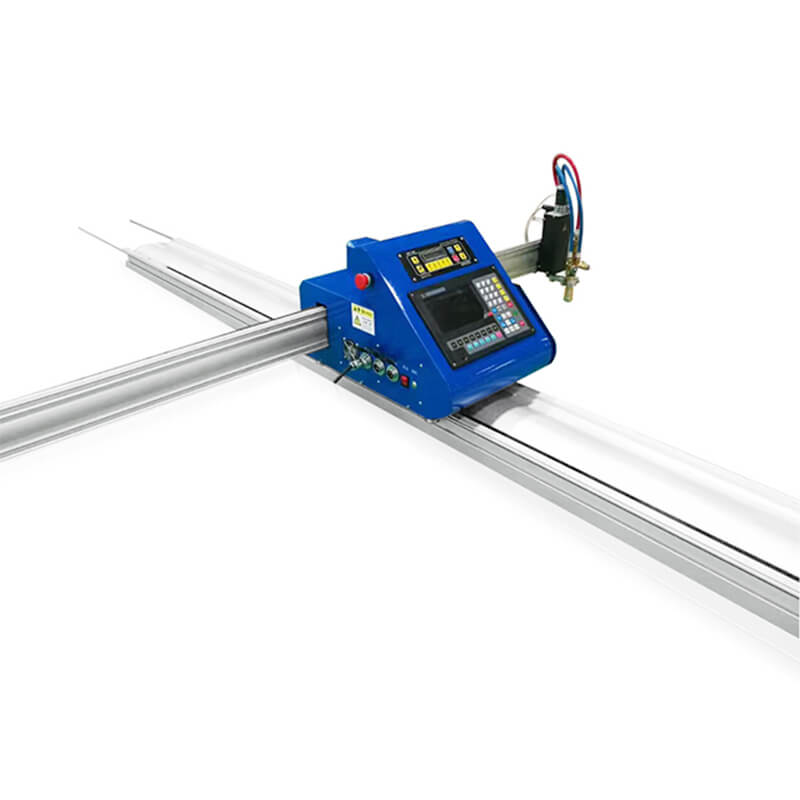

Portable CNC Plasma And Flame Cutting Machine

The plasma cutting speed is high, especially during common carbon steel sheet cutting, the plasma cutting speed is 5-6 times that of flame cutting.

Low price,you still need to expect best service,Cut mild steel with flame process. Cut high carbon steel, stainless steel, and other non-ferrous metal with Plasma process.Small size, great capability. High precision, low price.

You buy not because it’s cheap, you buy because it fits.

Portable CNC Plasma Cutting Machine Video

Flame cutting and plasma cutting dual function.

High precision, fast speed, narrow kerf width, minimum heat affected zone, the cutting face smooth without burr.

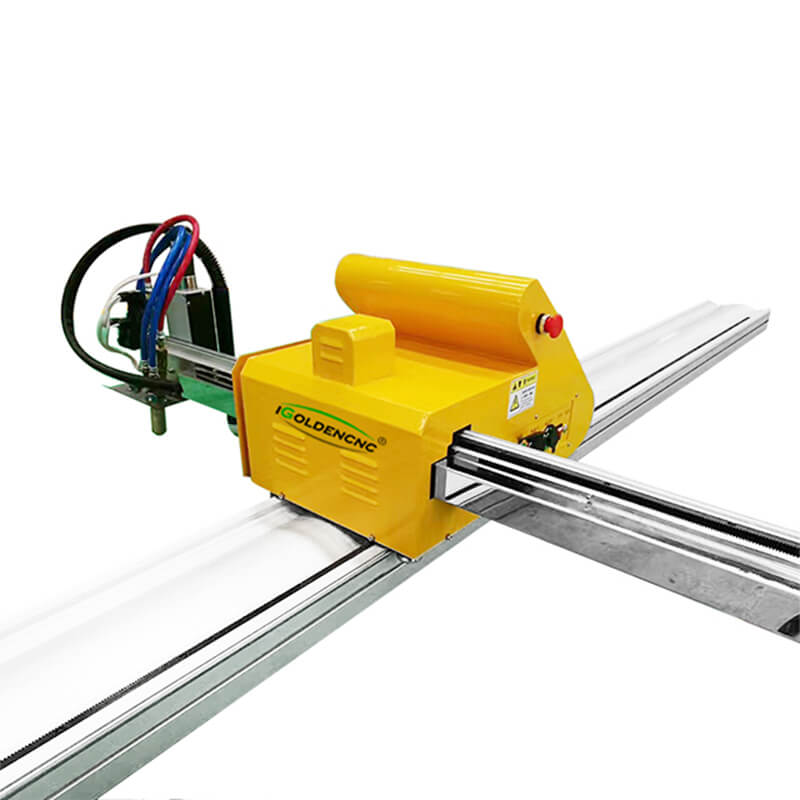

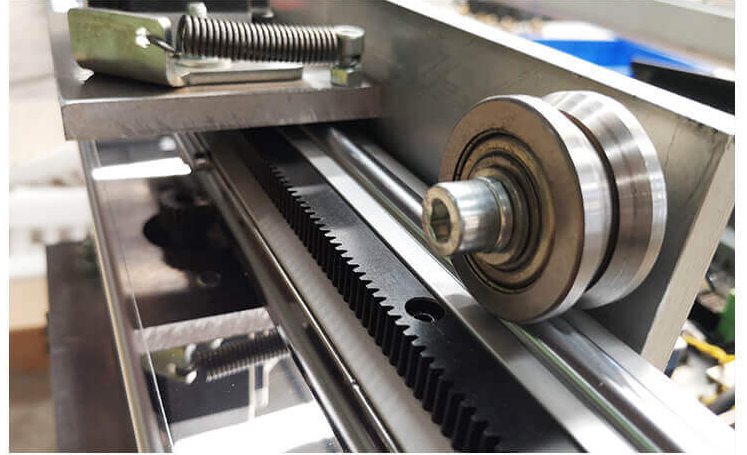

Track Rail

Independent research and development of aluminum alloy sleeper rails + double linear steel rails + precision rails Ensure high equipment accuracy, stable operation, installation and disassembly, flexibility and portability

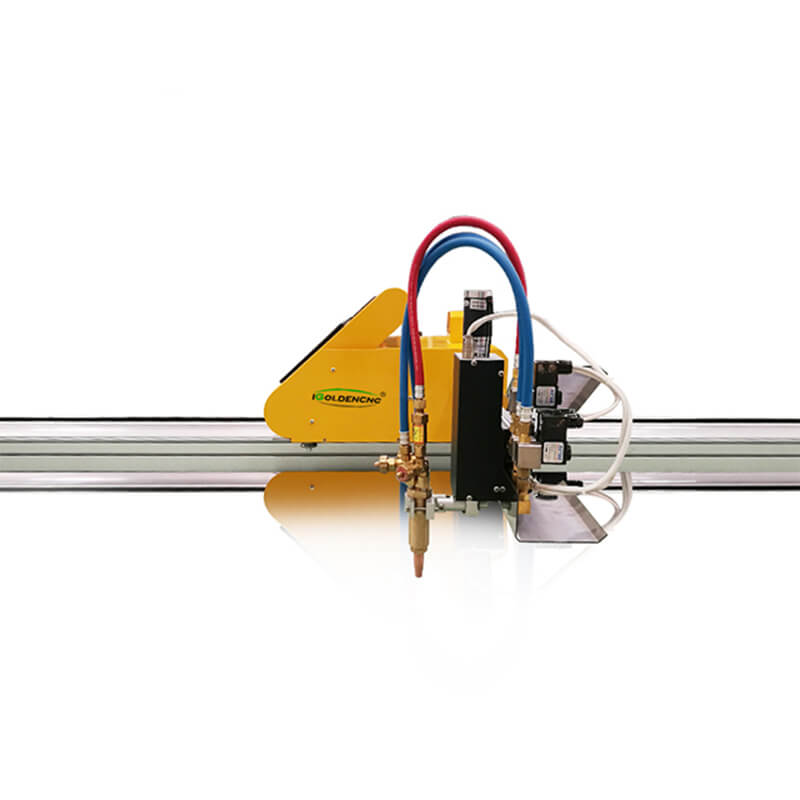

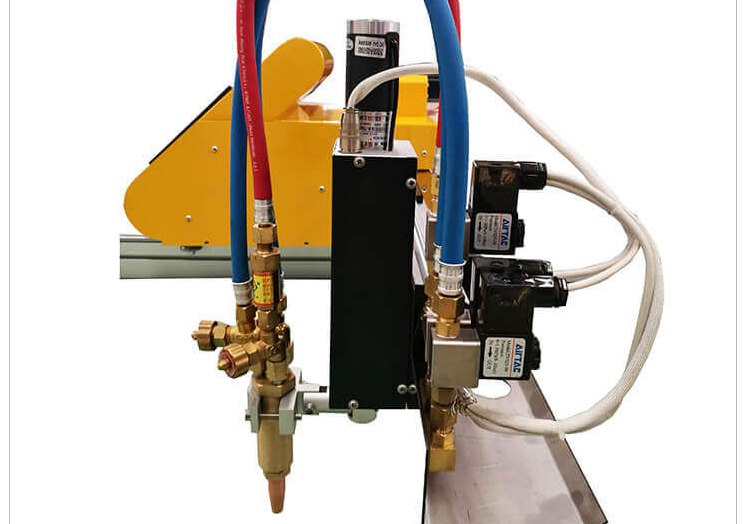

Flame Device

The air circuit adopts Taiwan Airtac solenoid valve to ensure safe use and service life.

High-temperature resistant hoses are used in the control part of the line to ensure line safety.

The special flame insulation board protects the gas path.

Shanghai Jiaoda Control System

Both cutting control system & torch height controller adopt LCD screen to display parameters,easy to adjust different functions by huttons.

High-precision gears and racks

All are driven by high-precision gears and racks (accuracy level 7) to make the equipment stable at high speeds.Each rack is surface-treated to prevent deformation and increase service life.

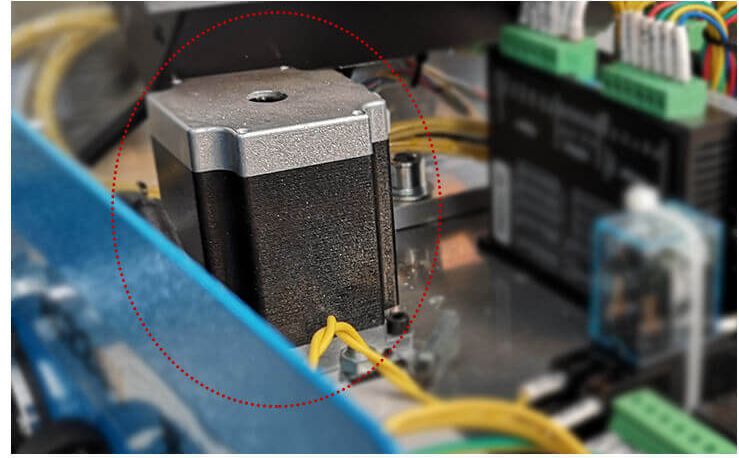

Stepper motor drive

It is driven by 57 # precision stepping motor, with stable running speed and fast running speed.

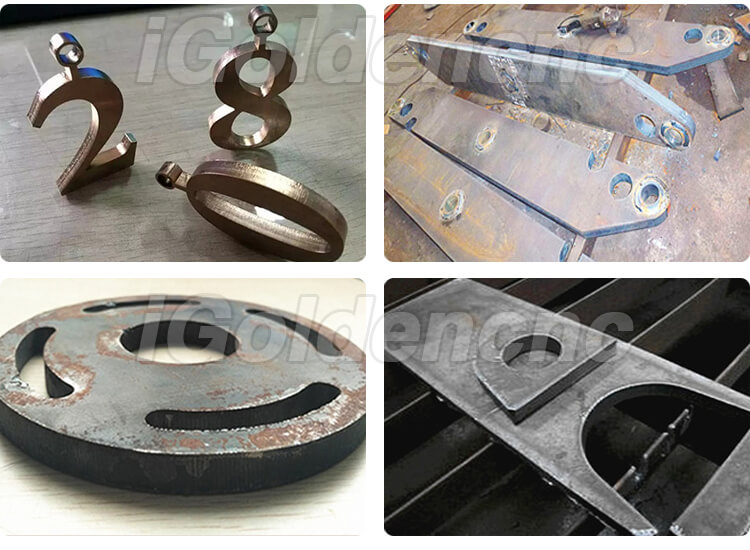

Portable CNC Plasma Cutting Machine Application

It can be used with oxy-fuel or plasma to produce one or multiple parts from simple to complex shapes. The portable CNC cutting machine is an ideal upgrade product to replace handheld flame-cutting equipment, handheld plasma cutting devices, profiling cutting machines and semi-automatic cutting carts.Widely used in machine tool manufacturing, petrochemical equipment, light industry machinery, shipbuilding, pressure vessels, engineering machinery, mining machinery, electric power, bridge construction, aerospace, steel structures, boilers, radiators, and other industries.

Portable CNC Plasma Cutter Parameter Configuration

Technical Data

| lasma source | 63A/100A/120A/160A/200A |

| Motor | Stepper/Servo |

| Control system | Starfire control system |

| Software | Fastcam |

| Guide rail | XYZ Axis Taiwan liner square guide rail |

| Ballscrew | Z Axis Taiwan TBI ball screw |

| Voltage | 3phase 380V/50HZ |

| Machine dimension | 3030*210*260(mm)580*450*420(mm) |

| Free parts | Software: Fastcam |

| Nozzle and Electrodes |

Flame or plasma cutting mode can be choose as customers’ need: Flame cutting mode is more suitable for cutting thick metal plate. But for the thin metal plate, plasma cutting mode is faster and the cutting edge is smoother. Flame torch and plasma torch can be exchanged very easily.

Production Workshop