Automated Linear ATC CNC Router Woodworking Machine

The most popular, industrial 3 axis ATC CNC router, perfect for professional CNC users, the Z series offers the robust construction that iGOLDENCNC products are known for, combined with a competitive set of configurations.

1325 atc cnc router 1530 2030 2130 3d wood cutting machine woodworking machinery with linear or carousel tool changer.

1325 4×8 Linear ATC CNC router machine is a very classic and popular ATC CNC router for sale. It is designed to help people out of boring work of tool changing, greatly saving the operation time. Once the wood piece uploaded and code set, the ATC CNC machine finishes the rest work. So it is a choice to make woodworking automatic.

ATC CNC Router Video

ATC CNC Router For Wood Parameter

|

X, Y Axis Working Area |

1300*2500/ 1500*3000/ 2000*3000/2000*4000mm |

|

Z Axis Working Height |

250mm |

|

Positioning Accuracy |

0.03mm |

|

Re-positioning Accuracy |

0.02mm |

|

Body Structure |

Heavy-duty Welding Body |

|

X, Y Axis Structure |

Linear Guide Rail, Gear Rack |

|

Z Axis Structure |

Linear Guide Rail, Screw |

|

Max. Running Speed |

50000mm/min |

|

Max. Working Speed |

30000mm/min |

|

Spindle |

9.0kw Air-cooling Spindle |

|

Spindle RPM |

24000rpm/min |

|

Working Voltage |

AC 220V/ 380V, 50-60Hz |

|

Machine Weight |

1800/2000/2300/2500kg |

Configuration

|

Spindle |

HQD Air-cooling ATC Spindle (Italy HSDSpindle Optioned) |

|

Worktable |

Vac-sorb Worktable with T-slot (Vac-sorb Worktable Optioned) |

|

Gear Rack |

Taiwan xinyue |

|

Electric Components |

France SCHNEIDER |

|

Driver |

Servo Motor |

|

Tool Setting |

Automatic Tool Sensor |

|

Optioned |

Rotary Device, Automatic Baiting, Double Worktable, Positining Cylinder |

If you need more detailed information, please inform us as soon as possible.

ATC CNC Router Machine With Automatic Tool Changer Features :

1. The bed body steel structure is welded with thick-walled square tubes, and is subjected to vibration aging treatment. It is durable and does not deform

2. Z-axis adopts Taiwan TBI ball screw, Taiwan high-precision Hiwin linear guide, high precision and more durable.

3. 8 Pcs Linear automatic tools changer, fast speed changer tools, high efficiency for woodworking.

4. Weihong system with break point specific memory, power outages continued carving, processing time forecast etc.

5. Vacuum table with double layer hard PVC,it has big suction and will not deform for a long time.

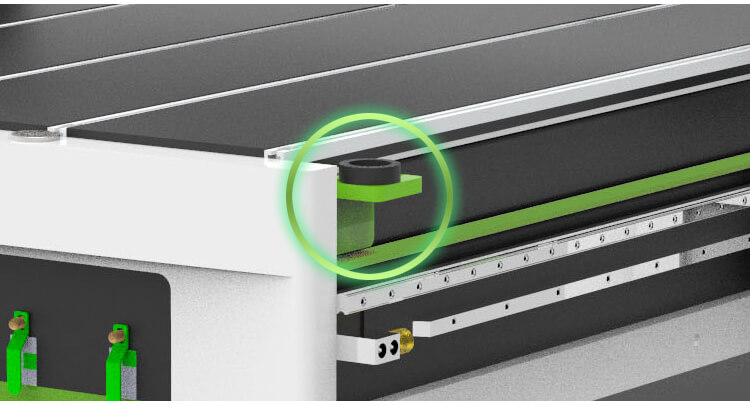

In-line tool change tool magazine

With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

Add a lock tool holder at a suitable position to facilitate customers to disassemble the tool.

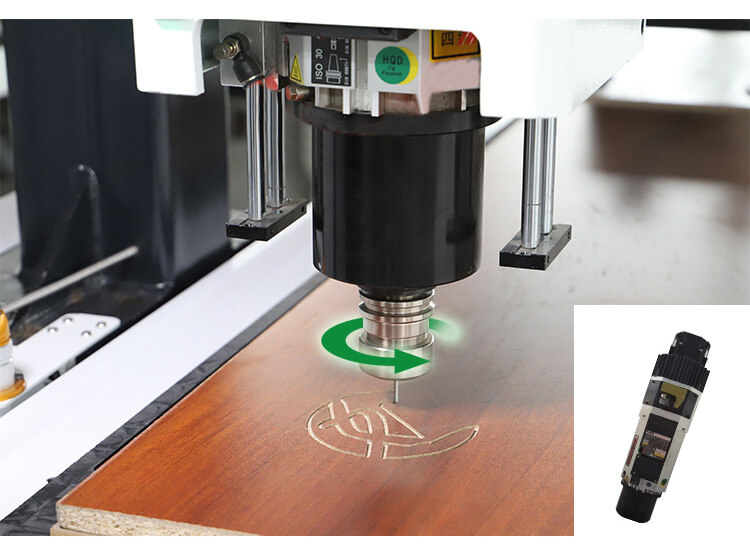

9KW HQD Air-cooling ATC Spindle

(Italy HSD Spindle Optioned)

21 inch screen-Integrated cabinet

Taiwan Syntec control system

Control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

Application

Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

Contact Us Today to Get Price!

Reviews

You should take your time to carefully assess the capabilities and pricing of each CNC router option you’re considering. Not all manufacturing facilities are the same, therefore it is recommended that you take the following factors into account:

The size of your site: first off, you should have an estimate of how much space you’ll have for your new CNC cutter. State-of-the-art equipment won’t be of much use to you if you don’t have enough room for a dedicated workstation!

Your final product: are you going to be cutting up a variety of materials? How big are your products? How many of them are you looking to manufacture every day? These are just some of the things you should consider when choosing the appropriate CNC router.

Your budget: while you probably don’t want to go for the cheapest option available, your budget is an important factor to consider, nonetheless. Just like with any product out there, CNC cutters come in all shapes and sizes, and some of them are heavily overpriced. Reach out to an expert for an opinion on the various choices, and do your own research online before you place the order.

ATC machines can be of two main types based on the magazine shape. The carousel type and linear type are the two types of ATC available.