A portable edge banding machine is a compact and lightweight version of an edge banding machine that is designed for on-site or small-scale edge banding applications. Unlike larger, stationary edge banding machines, portable models offer greater mobility and convenience, allowing users to bring the machine to the workpiece instead of vice versa.

Portable edge banding machines are designed to be compact and lightweight, making them easy to transport and maneuver. This feature is particularly beneficial for on-site or mobile applications.

Manual or Semi-Automatic Operation: Depending on the model, portable edge banders may offer manual, semi-automatic, or automatic operation. Some machines may require manual feeding of the edge banding material, while others have a feed mechanism for increased efficiency.

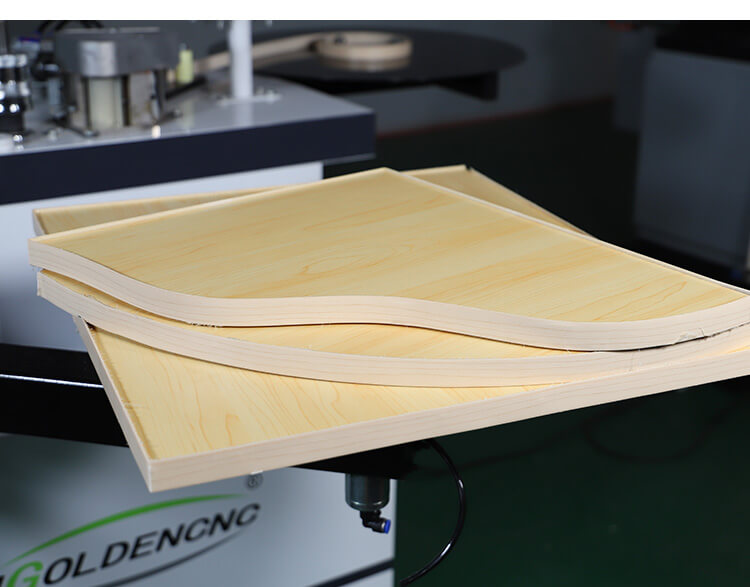

These machines are versatile and can typically work with various edge banding materials, including PVC, ABS, wood veneer, and other tapes commonly used in furniture manufacturing.

Trimming Unit: A trimming unit is integrated into the machine to trim excess edge banding material flush with the surface of the workpiece. This helps achieve a clean and professional finish.

End Trimming Unit: Some portable edge banders include end trimming units for cutting the edge banding material at both ends of the workpiece. This contributes to a neat and consistent appearance.

Trimming and Finishing: Once the edge banding material is applied, trimming and finishing operations are usually done manually. The user can use hand tools like trimmers, routers, or scrapers to remove excess material and achieve a clean and smooth edge. Portable edge banding machines may not have built-in trimming or finishing units.

Technical Parameters

| Function | Glue edge sealing – trimming |

| Voltage | 220V |

| Power | 2300W |

| Heating time | 5-10min |

| Edge width | 10-50mm |

| Trimming height | 10-50mm |

| Belt break method | Automatic belt break |

| Glue capacity | 1000ml |

| Gluing method | Double-sided adhesive |

| Size | 850*460*400mm |

| Weight | 34KG |

Portable edge banding machine Features

1. With the timing break function, it can realize flexible switching between feeding and cutting.

2. Equipped with suction cups, it has the advantages of strong bearing capacity and strong stability.

3. Adopting intuitive digital display operation panel, it is easy to operate.

4. Edge banding materials include PVC, veneer, melamine, plastic and other materials. Parameters

Mini Portable edge banding machine

Portable edge banding machines offer a practical solution for those who require flexibility and mobility in their edge banding processes, making them well-suited for smaller workshops, on-site installations, or projects with space constraints.

Portable edge banding machines often come with features like built-in handles, wheels, or a carry case to facilitate easy transportation. This mobility is beneficial for users who need to move the machine between different job sites.

Limitations: While portable edge banding machines offer convenience and mobility, they may have certain limitations compared to larger, stationary machines. Portable models may not be suitable for high-volume production or heavy-duty applications. They may also have narrower material width and thickness capacities. Additionally, the trimming and finishing operations may require separate tools or techniques.

Ease of Use: Portable edge banding machines are designed with user-friendly features to simplify the edge banding process. They typically have intuitive controls and adjustable settings for edge banding material thickness, feed speed, and temperature (if applicable). This makes them accessible to both professionals and hobbyists.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.