CNC Tombstone Stone Engraving Machine Stone engraving machine, also known as stone cnc router, granite engraving machine, is a highly automatic CNC machine tool which takes tool bits for carving & engraving works on different materials, including marble, granite, quartz, bluestone, jade, artificial stone and ceramic, glass, plastic and other hard materials.

Stone Granite Cutting & Engraving Machine

The CNC Tombstone engraving machine can carry out various complicated works, such as linear carving, character carving, 2D flat engraving, 3D relieving, shadow carving, cutting, chamfering, drilling, etc.

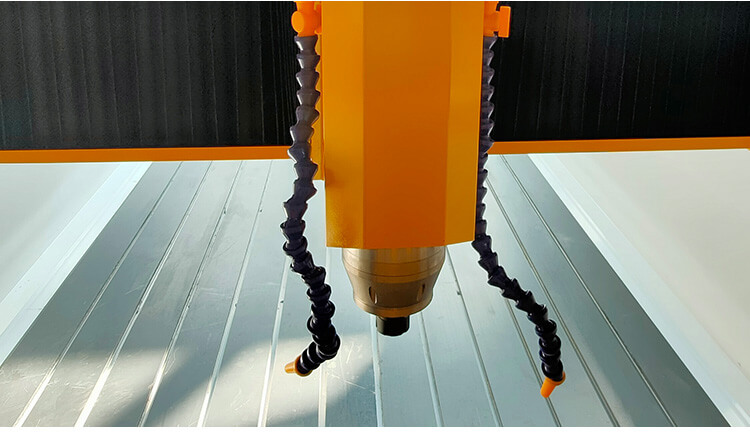

This Stone Carving Machine adopts a numerical control system, three-axis linkage, double row four-row slider, constant power spindle motor, two-way tool cooling system, with stable running, high precision, and high-efficiency advantages, suitable for processing marble, granite, bluestone, jade, agate, copper plate, and aluminum plate and other materials.

Affordable Stone CNC Router For Sale

A CNC stone router machine is a fully automatic computer-controlled machine tool capable of carving and cutting marble, granite, ceramics, ink-stone, jade, headstone, tombstone, artificial stone, glass, quartz, blue stone, natural stone to make cabinets, arts, crafts, inscription, Buddhas statues & sculptures. It is compatible with a variety of CAD/CAM design software. It is equipped with professional router bits and a bidirectional tool cooling system to effectively improve tool lifespan. It adopts computer numerical control system to realize 3D dynamic simulation display. It can do stone lettering, relief carving, shadow carving, line carving, stone cutting, and stone hollowing in home improvement, advertising, and industrial decorations.

Stone CNC Tombstone Machine Application

Home decoration industry:

Cutting & engraving of countertops and stone components for doorsteps, staircases & thresholds, flooring, fireplace, TV background wall, fence, etc.

Construction & building industry:

Building curtain wall, concrete panels, architectural components, street furniture, ventilated facades, staircases, bridge armrest, European-style window, etc.

Funeral industry:

tombstone, Monument, fences, stone sculpture and other kinds of stone components for funeral purposes.

Artworks & advertising industry:

inlays and mosaics, garden antique sculpture, carving and sculpturing, etc.

How Does A Stone CNC Machine Work?

A stone CNC machine is a computer-controlled cutting machine that uses diamond-tipped bits to carve stone. The machine is attached to a computer that sends instructions to the cutter, allowing for precise carving and intricate designs.

The machine works by first creating a digital model of the object that is to be carved. This model is then sent to the CNC machine, which uses it to create a path for the cutter. The cutter then follows this path, carving the stone according to the digital model.

Some machines are capable of very precise cuts, down to fractions of an inch. They use bits made from tungsten carbide or diamond, which can cut through stone with ease. The machine is usually powered by compressed air that moves the cutter along the surface of the stone at a rapid speed. It may be attached to a frame that sits atop the stone.

A stone CNC machine can be used to create a wide range of objects, including sculptures, tablets, and architectural pieces. The cutter works by tracing along with a digital model that was created beforehand on the computer. This design can be changed at any time while the object is being carved, adding another layer of flexibility to this machine.

How to Buy a Stone CNC Router Machine?

- Enquiry. Feel free to tell us what material you want, what is your max working size, and what product you want to do. The budget is also welcome.

- Free Quotation provided. We will send our quotation sheet with machine configuration, photos, videos, and prices to you according to your request.

- Launch the order. Your company will arrange the deposit, and we start the machine production from 3D design, machine body welding, machining, painting spare parts preparing, manufacture, and inspection.

- Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working for you. After the confirmation, the stone cnc router equipment will be shipped by sea through my or your agent.

- After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24 hours online to answer customer questions.

- Feedback. We are expecting feedback from our customers. Please tell us how you feel about machine quality and service. If you have more ideas to help us improve, that will be very appreciated.

I customized a stone engraving machine at IGOLDENCNC, which was manufactured according to my requirements from design to appearance. I have to say that they have great technology and will continue to cooperate with IGOLDENCNC next time.