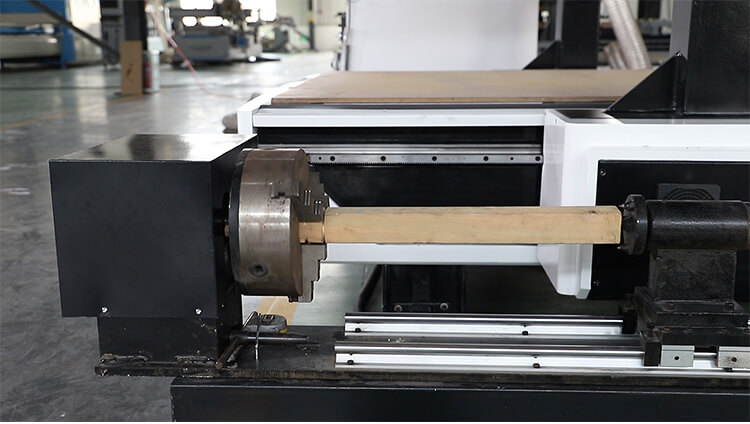

This CNC wood furniture machine is a multifunctional CNC wood router machine that can process a variety of products. it is a multifunctional machine,this machine contains ATC Function.So it can be used in making cabinet furniture.It not only supports automatic tool change, but also installs two machining axes, namely horizontal spindle and rotary axis. So this machine It has high work efficiency and is widely used in the cabinet furniture industry. And the horizontal spindle can be used to drill and milling the keyhole and hinge for door making. The rotary axis can be used to make furniture legs, such as chair legs, table legs, sofa legs and many other three-dimensional sculpture projects.

5×10 Nesting CNC Router Machine

1530 CNC router 5×10 ATC spindle machine with a rotary device is used mainly for the automatic carving of hardwood, MDF, 3D objects, cabinets, doors, staircase handrails, wooden pillars, stool legs, table legs, etc. The table size and rotary diameter can be ordered on your request. Affordable 5×10 CNC router ATC machine is now for sale at the best price.

ATC Nesting CNC Router with Rotary Device Features

- The rotary device on CNC router table 5×10 is portable. And it also can be detached in the process of transporting.

- ATC machine always has a more firm and reasonable structure. It is easy to operate and durable for long time heavy-duty work.

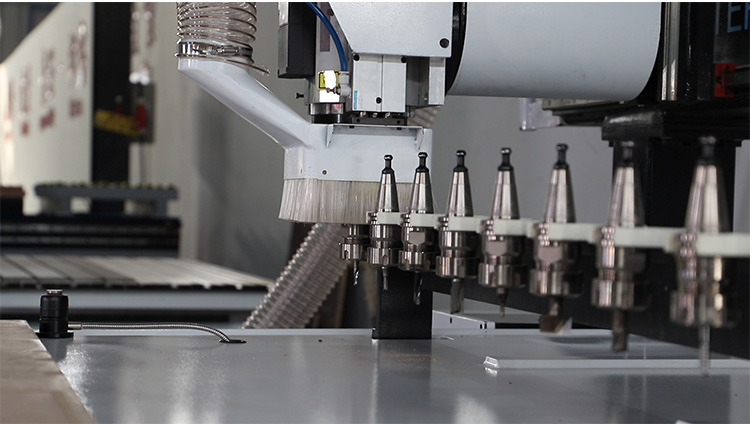

- Italy HSD air cooling ATC spindle has a top speed up to 24000RPM, which greatly improves working efficiency.

- Table 5×10 always means 1500x3000mm, we can also customize it on your request.

5×10 Nesting CNC Machine is a Wooden Furniture production line, it includes loading equipment, auto-feeding equipment, Nesting CNC Router with auto tool changer, unloading equipment, it automatic the whole process of MDF prepare, feeding, fixing, cutting, carving and unloading; best choice for Wooden Furniture making.

A 5×10 Nesting CNC Machine is an invaluable tool for industries that work with large sheet materials, offering the ability to efficiently process, nest, and cut components with precision. Its automatic nesting and CNC control capabilities help optimize material utilization, improve productivity, and reduce production costs.

What is the difference between the 3 axis and 4 axis CNC machine?

3 axis: the spindle is vertical and used for making flat working and engraving.

4 axis: the spindle can rotate 0-180 degrees, which is used for 3D processing.

4 Axis CNC Wood Machine Applications:

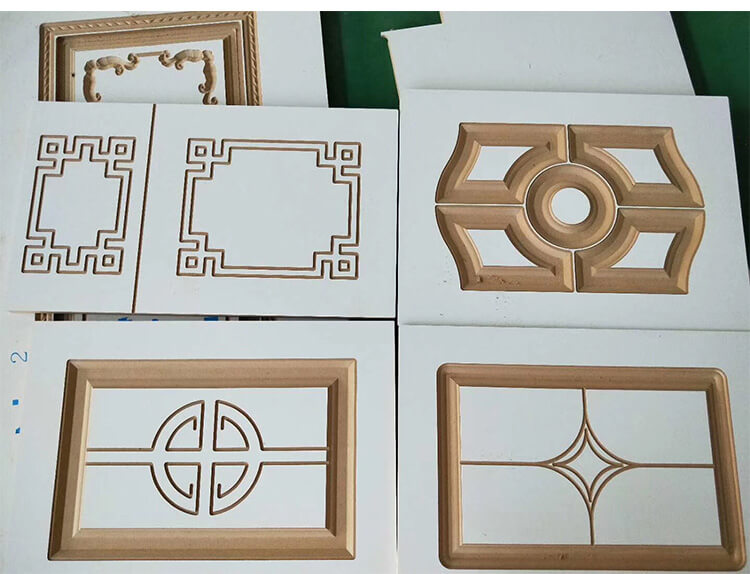

Furniture Manufacturing: Craft intricate and detailed designs on wooden furniture pieces, including tables, chairs, cabinets, and decorative panels.

Cabinet Making: Create precise cuts and joinery for kitchen cabinets, bathroom vanities, and storage solutions.

Signage: Produce custom signs, plaques, and decorative wooden signs with high-quality lettering and graphics.

3D Carvings: Carve intricate 3D designs, reliefs, and sculptures on wood for artistic and architectural applications.

Prototyping: Rapidly prototype and test new product designs or components with precision.

Art and Crafts: Explore creative woodworking projects such as intricate wood carvings, inlays, and wooden artwork.

Panel Processing: Accurately size and shape wooden panels and sheets for various applications.

Types of Nesting CNC Machine

ATC CNC Nesting Furniture Making Machine

Here are two type of ATC nesting CNC router for cabinet and furniture. One type is the linear ATC CNC nesting machines, and another is the ATC wood nesting machine with carousel tool magazine. And the automatic tool change spindle of this panel furniture CNC making machine is a top-brand high-power spindle with fast processing speed. The nesting machine bed is specially customized and has very high stability. This ATC wood nesting CNC machine is equipped with an independent tool changer magazine. Any tool can be placed in the magazine. The tool can be changed automatically according to different processing techniques during processing, which saves the time of manual tool changing. With the highest configuration, this type of nesting CNC router for sale is widely used for customers of various types of processing.

Multi-functional Nesting CNC Furniture Manufacturing Machines

Actually, IGOLDEN CNC Machinery Company provides many different types of nesting CNC machines for sale with many different functions, such as CNC wooden door lock making machine for sale, nesting CNC cabinet door making equipment with saw, auto nesting CNC feeding furniture making machine, automatic furniture making machine with drill, CNC nesting router machine with two worktables, labeling CNC nesting machine for sale, intelligent labeling and nesting cell, etc. They are all entry level nesting machines that added with different processing tools like CNC drill bits, saws, ATC spindles, worktables, labeling system, loading and unloading system, etc, to achieve more processes.

Single-head Nesting CNC Machine

This nesting machine is mainly used for cutting, grooving, engraving, and drilling vertical holes on plates. Generally, friends who have just entered the furniture industry will choose this entry level CNC nesting router machine. Because it is the most basic nesting machine for sale and this kind of nesting CNC machine price is relatively cheap. Therefore, it is also named as the best nesting CNC machine for beginners or CNC nesting router for small business. The disadvantage of such a type of wood nesting CNC router machine is that there is only one machining spindle and can not realize complex nesting CNC projects. If you want to perform multiple processes, you need to manually change several different tools. Of course, very few processing plants now use this machine because of low production efficiency.

Multi-process CNC Nesting Machine

The multi-process nesting machine mainly refers to double process nesting CNC machine, three process nesting CNC machine, or four process nesting CNC router. What does the multi process mean? It means that the multi-functional nesting CNC machine is equipped with multiple machining spindles, which can continuously and uninterruptedly complete the work of cutting, slotting, punching, cutting, etc. No manual tool changing is required, and the processing speed is more than three times faster than ordinary single-head nesting machines. Manufacturers of a little scale and some newcomers with sufficient funds will choose this CNC machine.

The biggest highlight of the double-process nesting CNC machine is that a drilling package is added to the nesting machine. Therefore, this type of nesting CNC machine for sale includes a single spindle router with row drilling, a dual spindle CNC nesting machine with row drilling, automatic tool change spindle nesting CNC with row drilling. This type of nesting CNC can realize rapid vertical drilling and can automatically change the CNC drilling tool according to different hole positions. Therefore, the production efficiency of this type of CNC nesting cutting machine is very high.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.