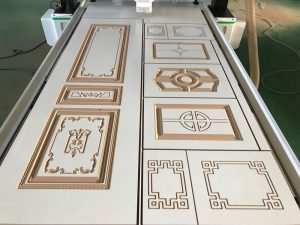

A CNC wood router is a type of automatic wood CNC machine for smart 2D & 3D routing, cutting, carving, drilling, grooving, or milling on most popular woodworking projects, including wood crafts, wood arts, wood signs making, cabinet making, wood door making, wood gifts, wood toys, wood modeling, decorations, wardrobe and other wood furniture making.

– Furniture Industry –

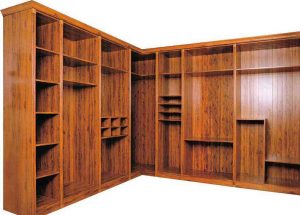

Wooden furniture. Wooden furniture is made of solid wood and various wood composite materials such as blackboard, fiberboard, plywood and particleboard. The production of this type of furniture mainly involves wood carving machines, ATC CNC engraving machines, and automatic loading and unloading engraving machines and other CNC equipment.

ATC CNC Router Related Products

1325 4 Axis Wood CNC Router

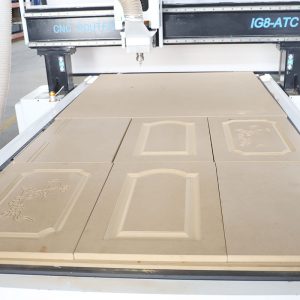

ATC CNC router machine has two types of tool magazines: linear and carousel. Both of them can be installed beside the spindle or on the side of the machine bed. By changing different tools automatically, the ATC CNC machine can complete multiple and complex woodworking processes at one operation.

Atc CNC Router With Automatic Tool Changer

ATC CNC router machine has two types of tool magazines: linear and carousel. Both of them can be installed beside the spindle or on the side of the machine bed. By changing different tools automatically, the ATC CNC machine can complete multiple and complex woodworking processes at one operation.

Linear ATC CNC Router Woodworking Machine

ATC CNC router machine has two types of tool magazines: linear and carousel. Both of them can be installed beside the spindle or on the side of the machine bed. By changing different tools automatically, the ATC CNC machine can complete multiple and complex woodworking processes at one operation.

3 Axis Swing Head ATC CNC Router Woodworking Machine

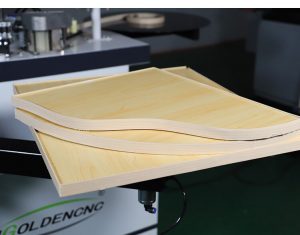

3 Axis CNC Router Machine is mainly for 3D wood carving, can do more complex woodworking such as side engraving on wood than 3 axis CNC. ATC HSD Spindle automatic change tools from tools changer, during all process no manual assistant needed, saves a lot of time and fewer operation needed;

Atc CNC Router Wood Carving Machine with Pinch Roller

ATC CNC router adopts a linear tool changer with the advantages of fast tool change and small guide rail wear. With independent tool magazine, it can automatically change the required tool during machining of the work piece without stopping work. Multiple processes are completed in one operation, greatly improving work efficiency.

Wood CNC Router Rotation Head With Rotation Table

4 Axis CNC Router Machine is mainly for 3D wood carving, can do more complex woodworking such as side engraving on wood than 3 axis CNC. ATC HSD Spindle automatic change tools from tools changer, during all process no manual assistant needed, saves a lot of time and fewer operation needed;

3d Atc Auto Tool Changer Wood Woodworking Machine

4 Axis CNC Router Machine is mainly for 3D wood carving, can do more complex woodworking such as side engraving on wood than 3 axis CNC. ATC HSD Spindle automatic change tools from tools changer, during all process no manual assistant needed, saves a lot of time and fewer operation needed;

– Nesting CNC Projects / Solutions / Applications –

The nesting CNC machine is a computer numerical control equipment specially designed for the production of panel furniture line. It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.CNC router nesting machine is used to carve all kinds of two-color plate signs, plexiglass, 3D billboards, two-color figure statues, embossed medals, organic plate embossing, 3D door characters, etc.

Nesting CNC Related Products

Kitchen Cabinet Door Furniture Woodworking Nesting Machine

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

1325 Furniture Making Machine CNC Nesting Machine

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

CNC Nesting Machine with Loading and Unloading Platforms

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

ATC Linear CNC Nesting Machine For Wood Cutting

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

Automatic Labeling CNC Nesting Machine For Furniture Making

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

Automatic CNC Router With Saw Blade Cutting Machine

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

Linear ATC CNC Nesting Machine with Double Platforms

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

1530 ATC Wood Engraving Machine with Drilling Holes

ATC Wood Engraver adopts disc type automatic tool changer. A variety of tools are automatically replaced according to the processing requirements. The faster tool change speed ensures the machine has high processing efficiency. The right side of the spindle is equipped with a row drill for side punching.

–Panel Furniture Production Line Subsidiary Equipment–

The main production equipment of the panel furniture production line is composed of a variety of numerical control equipment such as CNC cutting machine, edge banding machine, side hole machine, laminating machine, polishing machine and so on.

Subsidiary Equipment Related Products

Swing Folding Arm Woodworking Edge Banding Machine

The edge banding machine, is used to band the straight and curved panel edges for custom furniture production. A woodworking edge banding machine falls into the manual edge banding machine and the auto edge banding machine, specially designed for shops and companies looking for efficient and precise edge banding service and solutions.

Single Head Hinge Drill Machine

Nesting CNC machines are regarded as the best furniture manufacturing machines by cabinet makers and furniture manufacturers to set up a furniture production line or realize their custom furniture making projects, plans, and ideas. As a core CNC machine for furniture making, the CNC nesting machine is widely used to cut, drill, punch, groove, pocket, and engrave various wooden boards. With the help of automatic nesting software, the nesting CNC router can maximum the utilization of a wood panel and minimize cutting time and material waste.

Double Heads Hinge Boring Machine For Drill

The double-head hinged drill machine can adjust the drilling position longitudinally and horizontally, which is convenient and quick to adapt to the drilling processing requirements. It is an ideal equipment for cabinet, wardrobe and door processing manufacturers

Portable Edge Banding Machine for Small Shops

The edge banding machine, is used to band the straight and curved panel edges for custom furniture production. A woodworking edge banding machine falls into the manual edge banding machine and the auto edge banding machine, specially designed for shops and companies looking for efficient and precise edge banding service and solutions.

We have been experienced in exporting the CNC machine for over 12 years, familiar with the different requirementsfrom all kinds lines. Meanwhile, we insist the principle of “the best products, the most reasonable price, themaximum benefits for customers”, there are prestigious fame in the industry business field.

We have a strong professional technical team to provide the best products and have experienced managers with themost perfect price system integration schemes for our customers.