Stone processing center refers to a specialized machine or facility designed for the processing and fabrication of stone materials such as granite, marble, quartz, and other natural or engineered stones. These centers typically incorporate various technologies and tools to cut, shape, polish, and finish stone products for use in construction, interior design, monuments, and other applications.

Quartz stone CNC machining center is a stone fabrication machine for the making of stone kitchen sinks, stone countertops, basins, etc. It integrates edging, polishing, drilling, milling, and special-shaped cutting. One-key intelligent completion of conventional blanking, 45° bevel cutting, multi-angle arbitrary cutting, curve cutting, internal angle and basin hole cutting and other processes.

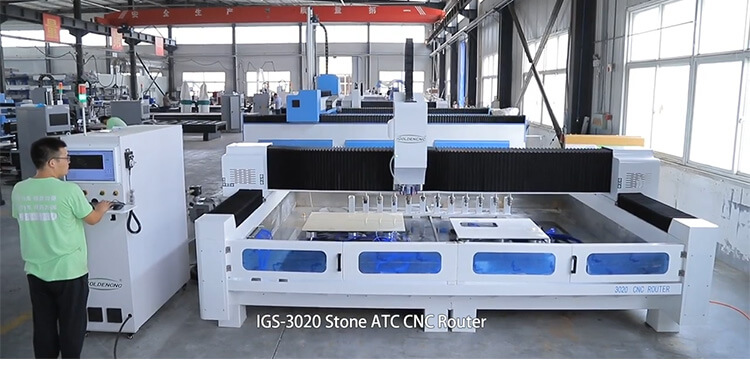

Stone processing center

A stone processing center, also known as a stone CNC machine or stone machining center, is a specialized machine designed for cutting, shaping, and finishing stone materials. It combines computer numerical control (CNC) technology with various tools and features to automate and enhance the stone processing workflow. Stone processing centers are commonly used in the stone fabrication industry for tasks such as cutting slabs, shaping countertops, engraving designs, and polishing surfaces.

Stone Carving Polishing Granite Cutting Machine

CNC machining center is a high-tech, high accuracy stone CNC machine center that specialized for all different kinds of stone, sintered stone and ceramic kitchen top, countertop, table edge complex carving processing. Stone CNC machining center is also a kind of automatic stone cutting tool or a special large-size stone CNC router which is composed of CNC granite engraving bits, such as stone spindles, stone automatic tool changers, stone processing systems, etc., to cut and polish quartz, marble, granite, artificial stones, and other natural stones.

Besides, it is also a commercial stone cutting and polishing equipment designed for marble slab cutting, tombstone milling, stone sculpture engraving, jade carving, quartz vertical drilling, granite polishing, 3D stone grinding, etc., which is widely applied in the mold industry, advertising industry, artwork decoration industry, kitchenware industry, stone industry in UK, USA, Canada, Russia, Australia, India, etc., to complete your CNC stone projects, ideas, and planes.

Features Granite Cutting Machine

CNC Control System

The stone processing center is equipped with a CNC control system that allows the operator to program and control the machine’s movements and functions. This enables precise and automated stone processing operations.

Cutting and Shaping Tools

Stone processing centers are equipped with different cutting and shaping tools, such as diamond saw blades, milling tools, and profiling wheels. These tools are mounted on motorized spindles and are capable of cutting, shaping, and profiling stone materials with high precision.

Slab Handling and Positioning

Stone processing centers often include features for handling and positioning stone slabs. This may include vacuum suction cups or clamping systems to secure the stone slab in place during cutting and shaping operations.

Water Cooling and Dust Extraction

Stone processing generates a significant amount of dust and heat. To address this, stone processing centers are typically equipped with water cooling systems to prevent tool overheating. Additionally, they have dust extraction systems to remove the generated dust and maintain a clean working environment.

3D Scanning and Modeling

Some advanced stone processing centers may have 3D scanning capabilities. This enables the operator to scan stone objects or templates and create accurate digital models for replication or customization.

Engraving and Surface Finishing: Stone processing centers can perform intricate engraving and surface finishing operations. This may include etching designs, texturing surfaces, or polishing stone materials to achieve a desired appearance.

CAD/CAM Software Integration

Stone processing centers work in conjunction with computer-aided design (CAD) and computer-aided manufacturing (CAM) software. The operator can create designs, generate toolpaths, and simulate the machining process using these software tools before executing the actual operations on the machine.

Suitable Materials:

- Marble, granite, jade, bluestone, black stone, and other stone materials, as well as ceramics, glass, plexiglass, PVC board, aluminum-plastic board, bamboo, and other materials.

- Hardstone such as granite can be carved to 5mm in layers

- Marble, bluestone, etc. can be engraved to 5mm at a time

Quartz Stone CNC Machining Center Application

A stone machining center is designed for the deep processing of quartz, marble, granite, slate, and other artificial stones. It can cut and drill holes, engrave letters and patterns, and mill and grind the stone surfaces. It is widely used to make kitchen countertops, bathroom washbasins, bar counters, coffee tables, stone statues and sculptures, tombstones and gravestones, and other artificial stone crafts and artworks.

Stone CNC Machining Center Advantages

- Fast speed, high precision, strong stability, low noise, and long service life.

- Automatic leveling function: It can correct the concave, convex and uneven slope of any stone surface. The software automatically generates a new program based on the floating of the stone surface, which conforms to the surface characteristics of the stone.

- Stable bed structure: The bed adopts high-quality steel structure and double beam design, and the gantry and work surface are respectively supported by reinforced beams. Therefore, it has the advantages of bearing load, no deformation, and high stability.

- Super cutting ability: Adopting high-power drive system coordinated with the spindle’s stable engraving, it has the features of greater torque force, smoother operation, precise and powerful cutting point. And Y-axis uses dual motor synchronous drive, it has the features of strong power, high stability, and can realize the process of 70mm Granite thickness.

- Longer service life: Use stainless steel sink, protection plate and other parts to fully protect the transmission parts and electrical components, so that the machine has a long service life.

- Advanced professional control system: It can be compatible with Type3 / Artcam / Castmate / pro-e / Ug / Cad / IIIustrator / Wentai / Jingdiao and other software.

- The working table of the marble engraving machine is a T-shaped steel bracket, using a full welding process and vibration aging treatment. Thus it can ensure the stable performance when the machine running at high speed, and continuous knife, keep the production processing surface is highly smooth.

- The CNC router stone engraving machine uses a high-power horizontal torque spindle, with large bearings. and with high speed, a large number of chips, and the motor is not easy to damage.

- Stone CNC routers are widely used in the Stone industry, stone tablet processing industry, art relief, advertising, decoration and decoration industry, ceramic industry.

- Perfect for Stone lettering, stone relief, stone yang carving, stone edging, stone line carving, stone cutting, stone hollowing.

Stone CNC Machining Center For Cutting And Polishing

Stone CNC machining centers for cutting and polishing offer significant advantages in terms of precision, efficiency, and repeatability compared to manual stone processing methods.

Cutting Tools: Stone CNC machining centers for cutting and polishing are equipped with various cutting tools, such as diamond saw blades or waterjet cutting heads. These tools are used to cut stone slabs into desired shapes and sizes with high precision.

Shaping Tools: The machine may also have shaping tools, such as milling cutters or profiling wheels, for creating intricate designs, beveling edges, or adding decorative elements to the stone surfaces.

Polishing Tools: To achieve a smooth and glossy finish, stone CNC machining centers are equipped with polishing tools, such as polishing wheels or discs. These tools rotate against the stone surface, applying abrasives or polishing compounds to remove imperfections and enhance the stone’s appearance.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.