Automatic tool changers (ATC) have become an essential feature of advanced CNC woodworking machines. By allowing fast, automated swapping of cutting tools, ATC systems greatly improve productivity and versatility for a wide range of wood fabrication tasks.

Woodworking Machinery ATC CNC Router

The ATC CNC router is used for cutting, carving, and shaping wood materials with precision. It can perform a wide range of woodworking operations, including routing, engraving, drilling, grooving, and 3D carving. The machine is capable of executing complex designs and intricate details on wood surfaces.

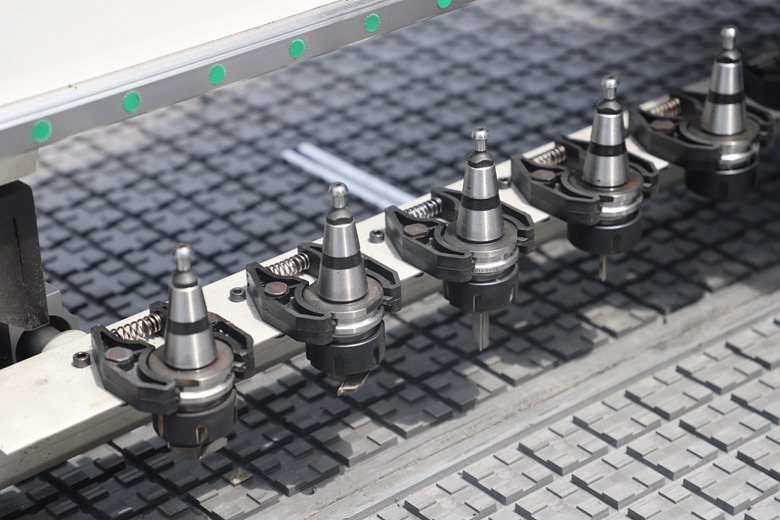

ATC machines contain a carousel tool magazine that holds multiple tools ready for use. The CNC controls automatically select the needed tool and command the ATC to retrieve it from storage. A robotic arm precisely locks the tool into the spindle for cutting, then replaces it when complete.

This enables rapid changing between tools like routers, drills and saws without manual intervention. Tools are securely held yet easily swapped out for maintenance. Tool breakage or wear doesn’t halt production.

ATC CNC router are versatile machines that can work with various types of wood materials, including solid wood, plywood, MDF (Medium-Density Fiberboard), particleboard, and more. They can be used for a wide range of woodworking applications, such as furniture manufacturing, cabinetry, sign making, decorative moldings, and architectural woodworking.

1. Function: Linear ATC CNC Router suitable for routing,drilling,cutting,edge chamfering,etc.

2. Precision: Excellent Spare parts,accurate precision detection instrument,which make sure the machine with perfect location and working precision.

3. High-speed: Adopt reducer direct design,high torque, high-energy, Y axis dual motor drive, runs smoothly with high efficiency.

4. Table: Double-layer compound grade board table design,rugged construction,non-deformation,with functions of instant adsorption and release.

5. Tool magazine: With an 8 slots Linear tool changer,tool changes to be performed quickly.

Applications

- Furniture Manufacturing:

- Used for cutting, shaping, and assembling furniture components.

- Ideal for producing intricate designs, joinery, and custom pieces.

- Cabinet Making:

- Efficiently produces cabinet parts, including doors, frames, and panels.

- Capable of intricate detailing and consistent production.

- Wooden Art and Craft:

- Creates detailed carvings, engravings, and artistic pieces.

- Suitable for custom art projects and mass production of decorative items.

- Architectural Woodworking:

- Produces elements like moldings, trim, and decorative architectural components.

- Ensures precise and consistent output for large-scale projects.

- Signage:

- Engraves and cuts wooden signs with precision.

- Can handle both simple and complex designs for commercial and decorative signage.

- Musical Instruments:

- Used in the manufacturing of wooden parts for musical instruments, such as guitars and violins.

- Ensures precision in the intricate components and assembly.

ATC CNC Woodworking Machinery Advantages

- Higher throughput from rapid tool changes

- Reduced non-cutting time improves efficiency

- Single operator can load/unload multiple jobs

- Single machine capable of many operations

- Improved accuracy from auto tool calibration

- Less scrapped parts from breakage downtime

- Simplified production of small batch sizes

Details about ATC CNC woodworking machinery:

Tool Magazines – Larger machines may contain tool magazines holding 50+ tools. Pneumatic or electric tool clamps securely lock tools ranging from 1/8″ bits to 10″ saws. Some machines use dual magazines for continuous production.

Tool Recognition – Sensors identify each tool so the CNC can apply the correct offsets for diameter and length. This ensures precise positioning regardless of tool changes.

Automated Processes – Beyond routing and drilling, ATC CNCs can automate sanding, edge banding, drilling, tapping, engraving and surface treatment using the right integrated tools and work handling.

Workflows – Common workflows include profiling; drilling/plunging holes; cutting templates and patterns; trimming/breaking edges; engraving details; and final sanding/finishing. Complex jobs with many steps are simplified.

Multi-Axis Motion – Higher end machines offer 4- to 5-axis simultaneous and independent axis control for sculpting true 3D forms. Gantries provide large working envelopes.

Nesting Software – For mass production, nesting software automatically arranges and sequences multiple parts to pack the work area and minimize tool changes/non-cutting travel.

Quality Control – Integrated measuring probes can verify part dimensions during machining for process control and to detect worn or broken tools requiring replacement.

With the right ATC CNC system, even small wood shops and job shops can take on more complex work previously outsourced due to the machines’ flexibility and highly productive tool changing capabilities. The automation improves throughput and allows concentrating on new product development.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.