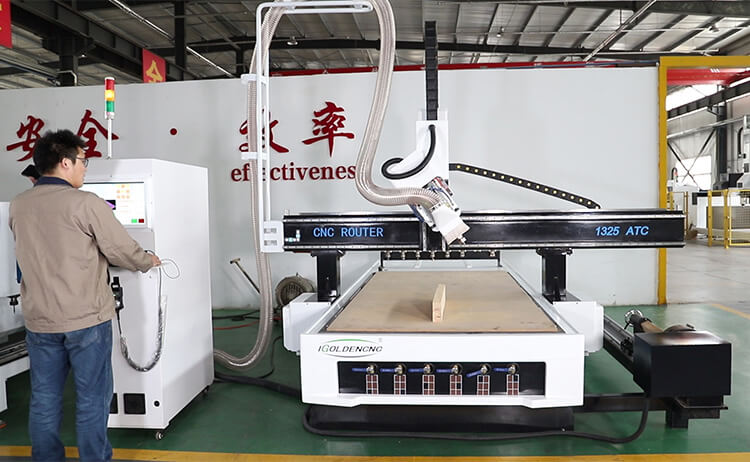

4×8 CNC Router

A 4×8 CNC router table refers to a computer numerical control (CNC) router with a cutting or milling bed size of approximately 4 feet by 8 feet. This size is suitable for handling large sheets of material, such as plywood or MDF, and is commonly used in woodworking, signage, and other industries.A vacuum table is an excellent feature for holding down workpieces securely during cutting, especially when working with sheet materials. Ensure that the CNC router you choose has a large enough vacuum table to accommodate the 4×8 work area effectively.

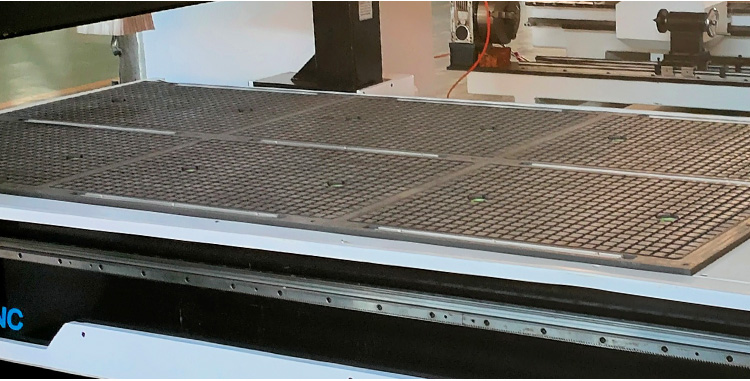

4×8 CNC router with vacuum table

The full vacuum table is more efficient and is suitable for cutting and engraving large flat panels of panel furniture.

The vacuum suction table means that the table of the engraving machine is vacuum suction. The function of vacuum adsorption is to put the workpiece on the worktable, turn on the vacuum pump, open the control valve, and directly suck the workpiece onto the worktable without clamping it with a clamp. At this time, the engraving machine starts to work, and the entire loading and unloading process does not exceed ten seconds, with high efficiency and fast speed. It is very suitable for the line carving of wooden doors and panel furniture.

The vacuum workbench can be divided into four, six, or eight areas. In this way, the adsorption function can be further enhanced. Now, the vacuum table with 6 zones is the most popular. We can also design the area according to customer needs. You only need to open the valve next to the vacuum table to perform the corresponding work in this area.

4×8 CNC router table with T-slot vacuum table

The T-slot vacuum CNC router table has a more flexible fixing method, which is suitable for processing irregularly shaped workpieces.

The aluminum T-slot table and the CNC router machine vacuum table have their own advantages, and we can’t simply say which one is better. From the point of view of the speed of fixing the workpiece, the CNC Router vacuum table is of course faster, only a little more than ten seconds, and it takes a few minutes to fix the work more efficiently than the aluminum T-slot table. However, certain materials and processing techniques are not suitable for CNC Router vacuum tables. Therefore, the desktop of the CNC router machine should be selected according to the workpiece material and processing technology.

If your processing materials need to be used, there are two work surfaces, an aluminum T-slot table, and a CNC router machine vacuum table.

Don’t worry, IGOLDENCNC has upgraded the traditional CNC router machine vacuum table and added it to the CNC router machine vacuum table. Aluminum T-slot profile, so the workbench has the advantages of both vacuum and T-slot.

When looking for a 4×8 CNC router table, here are some factors to consider:

- Cutting Area: Ensure that the actual cutting area matches your needs. The 4×8 specification typically refers to the maximum size of the material that can be processed.

- Construction and Rigidity: Look for a CNC router table with a sturdy and rigid construction. Rigidity is important for maintaining accuracy and precision during cutting operations.

- Spindle Power: The power of the spindle determines the cutting capabilities of the CNC router. Consider the type of materials you’ll be working with and choose a spindle power that suits your requirements.

- Control System: Check the control system and software that come with the CNC router. Intuitive and user-friendly software can make the operation of the CNC machine more efficient, especially for beginners.

- Vacuum Table or Clamping System: Determine whether the wood CNC router table comes with a vacuum table or another type of material holding system. A vacuum table is efficient for securing flat materials during cutting.

- Compatibility with CAM Software: Ensure that the CNC router is compatible with Computer-Aided Manufacturing (CAM) software. This software is used to generate toolpaths and control the CNC machine.

- Accuracy and Repeatability: Look for specifications regarding the accuracy and repeatability of the CNC router. These factors are crucial for achieving precise cuts and consistent results.

- Dust Collection System: A CNC router generates a significant amount of dust and debris. Consider a machine that includes or is compatible with a dust collection system to maintain a clean working environment.

Application:

Woodworking industry: all kinds of doors, windows, cabinets, craft wooden doors, paint-free doors, screen windows, craft fan windows, corrugated board processing, and wood processing of other furniture.

Advertising industry: advertising signs, sign production, advertising material cutting, blister molding, LED neon light production, and other materials for the production of advertising decoration products.

Handicraft industry: carving various exquisite patterns and characters on wood, bamboo, artificial marble, organic board, two-color board, crystal, and other materials.

IGOLDENCNC offers a variety of CNC wood router machines with many standard configurations for you to choose from. For instance, ATC CNC machines, 4 axis CNC machines, 3 axis CNC machines, multi-head CNC machines, mini CNC machines, best hobby CNC machines, stone CNC machines, and EPS CNC machines. In terms of worktable size, the best CNC router falls into 2×4, 4×4, 5×10, 4×8 CNC router, etc.

According to your different processing materials and processing requirements, we also provide customized production of CNC engraving machine. Whether it is the machine parts selection or machine processing size, we are committed to satisfying your diverse processing needs with the highest price/performance ratio. With an annual export volume of over 3,000 units, the best CNC machines from IGOLDENCNC are the first choice for your engraving industry.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.