CNC wood kitchen cabinet cutting machine offers numerous advantages in terms of precision, repeatability, and efficient production. It is commonly used in both small-scale and large-scale cabinet manufacturing operations, allowing for customization and mass production while maintaining high quality and consistency. These machines also reduce material waste, which is essential for cost-efficiency in the cabinet-making industry.

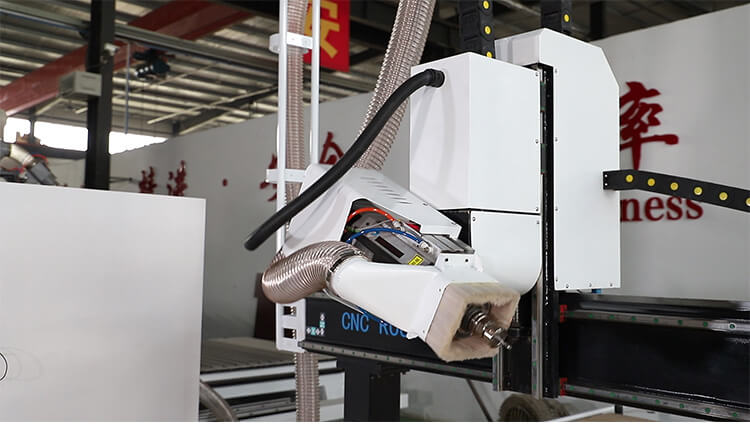

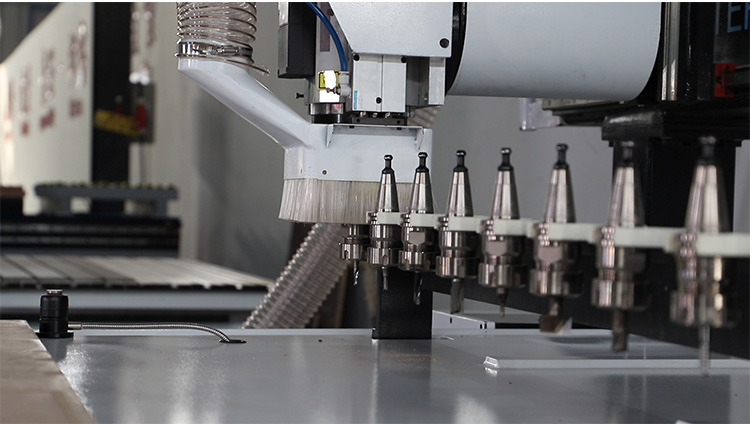

This function of the CNC machine kitchen cabinets greatly shortens the tool change time of the ordinary wood CNC cutting machine . CNC kitchen cabinets machine is used with an automatic loading and unloading platform, eliminating the need for manual lifting and saving labor costs.

Kitchen Cabinet Cutting Machine Advantage:

- Precision Cutting: CNC cutting machines provide high levels of precision in cutting materials. This ensures that components of kitchen cabinets are accurately cut to the specified dimensions, resulting in a perfect fit during assembly.

- Efficiency and Speed: Automated kitchen cabinet cutting machines operate at high speeds, contributing to increased efficiency in the manufacturing process. This is particularly beneficial in large-scale production where quick turnaround times are essential.

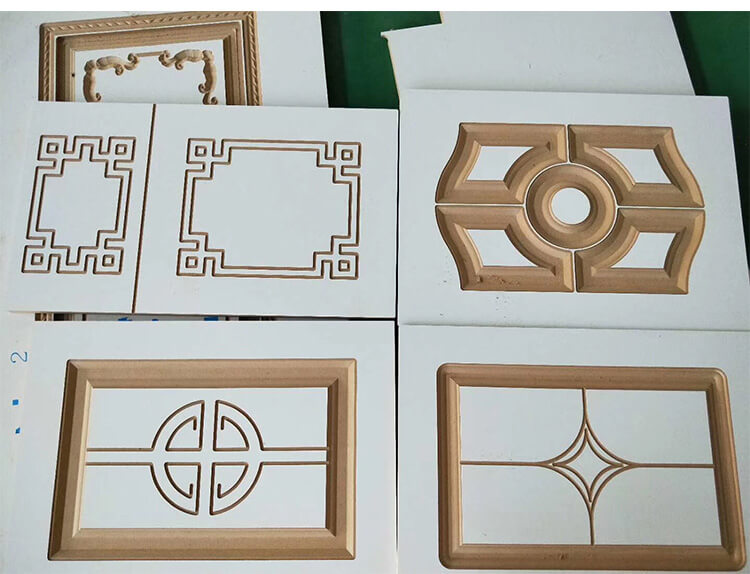

- Customization: CNC cutting machines allow for a high degree of customization. Manufacturers can program these machines to cut different shapes, sizes, and intricate designs, catering to a wide range of design preferences and customer requirements.

- Material Optimization: CNC cutting machines are programmed to optimize material usage, minimizing waste. This not only reduces material costs but also aligns with sustainable and eco-friendly practices in manufacturing.

- Complex Shapes and Patterns: These machines can cut complex shapes and patterns with precision, enabling the creation of intricate designs on cabinet doors, panels, and other components. This capability is valuable for achieving unique and aesthetically pleasing designs.

- Consistency in Quality: CNC technology ensures consistency in the quality of cut pieces. Each component is identical, eliminating variations that may occur with manual cutting methods and contributing to the overall quality of the finished cabinets.

- Seamless Joinery: CNC cutting machines can be programmed for precise joinery, including dadoes, grooves, and intricate joints. This results in seamless and strong connections between cabinet components, enhancing the structural integrity of the cabinets.

- Scalability: Kitchen cabinet cutting machines are scalable and suitable for both small-scale and large-scale production. They can handle a variety of production volumes, making them versatile for different manufacturing needs.

- Reduced Labor Costs: Automated cutting machines reduce the reliance on manual labor for cutting and shaping cabinet components. This leads to cost savings in labor expenses and minimizes the risk of errors associated with manual cutting.

- Workflow Integration: CNC cutting machines can be integrated into a larger computerized workflow, allowing for seamless communication between design software, cutting machines, and other manufacturing processes. This integration enhances overall production efficiency.

- Versatility in Materials: Woodworking Kitchen cabinet cutting machines can work with a variety of materials commonly used in cabinet making, including wood, plywood, MDF (Medium Density Fiberboard), particleboard, and more.

Specifically for Cutting Kitchen Cabinet Machine Parts

Modular work table/surface – The table should be adjustable and modular to accommodate different cabinet sizes and component styles. Modular fences, templates and fixtures can help with proper part positioning.

Strong cutting tools – Cabinet parts like sides, shelves, faces, etc. can be thick hardwoods or composites. Saw blades, knives or laser/waterjet need strength to cut efficiently.

Material handling/feeding – An automated/precise feeding system is needed to move sheets/boards/parts accurately to the cutting area. Rollers, vacuum tables, grippers help feed, register and secure materials.

Multiple operations – The machine should enable sequential/simultaneous cutting, drilling, trimming, edge shaping etc. to process parts with minimal operator handling.

Tool changes – Quick tool changes are important to switch between saws, drills, trimmers seamlessly based on part type. Pneumatic or electric clamping of tools.

Dust collection – Powerful dust extraction is needed to collect wood/composite debris from multi-axis, high-speed cutting operations.

Programming/nesting – Software optimizes material utilization through automatic nesting of cabinet parts layout. Generates CNC machine readable codes.

Finishing options – Integrate sanding/edgebanding to bring parts to a finished state ready for assembly.

Ergonomics – Comfortable operator controls and access. Safety light curtains or sensors around moving parts.

CNC Wood Cutting Machine Application

Kitchen Cabinet Production

The primary application is in the manufacturing of kitchen cabinets. CNC cutting machines are used to cut precise components such as cabinet doors, panels, shelves, and drawer fronts. Custom Cabinet Design: CNC technology allows for the customization of cabinet designs. Manufacturers can program the machine to cut intricate patterns, shapes, and details, catering to the specific design preferences of customers.

Furniture Manufacturing

Beyond kitchen cabinets, CNC cutting machines are employed in the production of various types of furniture, including wardrobes, entertainment units, and storage cabinets.

Architectural Millwork

CNC cutting machines are used for architectural millwork applications, cutting components for built-in cabinetry, paneling, and other architectural features in residential and commercial spaces.

Closet Systems

Manufacturers of closet systems utilize CNC cutting machines to cut components for shelves, drawers, and other organizational elements in custom closet designs. Commercial Cabinetry: In commercial settings, CNC cutting machines are used for the production of cabinetry and storage solutions in offices, retail spaces, and hospitality environments.

Panel Processing

These machines are employed in processing large panels of wood or composite materials. This includes cutting panels to size for various applications in woodworking.

Bespoke Furniture Manufacturing

Manufacturers specializing in bespoke or custom furniture use CNC cutting machines to create unique and one-of-a-kind pieces with intricate designs. Interior Design Elements: CNC cutting machines contribute to the production of interior design elements such as decorative panels, wall coverings, and architectural details.

MDF and Plywood Cutting

CNC cutting machines are particularly well-suited for cutting materials like MDF (Medium Density Fiberboard) and plywood commonly used in cabinet and furniture making.

High-Volume Production

These machines excel in high-volume production environments where efficiency, speed, and consistency are crucial. They can handle repetitive tasks with precision and speed, ensuring a quick turnaround. Woodworking Workshops: Woodworking workshops and factories use kitchen cabinet cutting machines as part of a larger production line, integrating them into the overall manufacturing process.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.