CNC nesting is a kind of CNC machining technology which refers to the process of laying out the cutting and engraving patterns to reduce the processing time and the amount of waste resource. In a word, CNC nesting technology aims to produce as many parts as possible with as little material as possible.

What Is Nesting in CNC Machines?

The nesting CNC machine is a computer numerical control equipment specially designed for the production of panel furniture line. It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.

Nesting CNC machine is mainly used to cut various wooden works. Generally, through the design of intelligent software, the nesting CNC routers can automatically optimize the typesetting design and generate the effect map. Besides, the nesting machine can also perform operations such as modification intuitively, and automatically generate various paths. Therefore, it can save sheets and improve sheet utilization. The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors. If you are a manufacturer of furniture production lines, this nesting CNC machine is definitely one of your indispensable CNC equipment.

Common classification of nesting CNC machine

Multi-purpose CNC cutting machine

A multi-process CNC cutting machine is a piece of numerical tracking equipment distinctively designed for manufacturing furniture product lines. The common multi-process nesting cnc machines include; double processes, three processes, and four processes CNC cutting machines. However, the CNC cutting machine under discussion, the multi-process device has uniquely emerged through manufacturing single and dual cabinet heads. Various heads bear diverging processing functionalities but aren’t limited to these features like cutting, slotting, and drilling. It’s also assembled with a row drill kit and 9 drill bit, which is used to auger holes horizontally. Punching reams with keen vigilance and avoiding punched out roundness is highly possible for several diameter holes. On turning the row of drills, the items are linked with all the nine drills rotated simultaneously without having to unlock the hole diameter that boosts the speed of drilling. With an assurance of a 30% efficiency rate, the multi-process CNC cutting machine is the most suitable for the manufacture of cabinets.

Automatic tool change CNC cutting machine

As an automatic tool change CNC cutter, this nesting cnc machine undertakes the automatic tool change function during processing and still accomplishes positioning, optimization, cutting, punching, slotting, and engraving. Equipped with a stand-alone tool magazine and each combination of tools designed to perform a key processing functionality on any non-metal material. The frame is embedded in a gantry moving column structure and all components of the device are manufactured and assembled with accuracy to enhance serviceability, firmness, quality of work, and endurance. Engulfed with all these benefits, this cnc nesting machine is widely used and revered for processing in the industry due to its automatic tool changer capability. Well, if productivity and beauty are your goals, this nesting cnc machine is the best-kept secret.

What Does A CNC Nesting Machine Do?

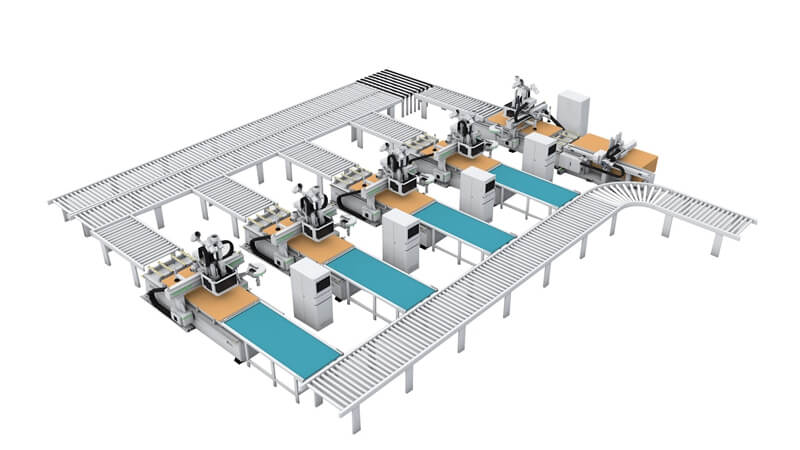

The CNC nesting machine is an automatic panel furniture production line, which is used for making wardrobe cabinets, cupboard cabinet furniture, computer desks, panel furniture, office furniture, wooden speakers, wooden kitchen utensils with cutting, milling, drilling, chamfering, punching, carving.

Due to the high processing efficiency, high processing accuracy and simple operation of this equipment, it can be combined with furniture design and dismantling software to achieve customization for different needs, so it is widely used in the furniture making industry.

Some people like to compare the CNC nesting machine with the CNC router. These two machines are just similar, but they don’t want to be the same. The nesting CNC machine is multi-axis rotation, and the CNC router machine is one for six and one for eight. Although the simple nesting CNC machine and the CNC engraving machine are moving in a gantry, the nesting CNC machine with a high configuration also moves in the gantry and the platform also moves. CNC router machines generally use small milling cutters and small power, and nesting CNC machines generally use large power and large milling cutters.

The functional characteristic of the CNC nesting machine is that it has many functions and a wide range of use. The biggest feature of this machine is that it can be continuously upgraded according to your product. When choosing machinery, it is also done according to needs. If you don’t need too many functions, you don’t need too many function configurations, and only require the product functions to be durable.

Intelligent CNC nesting instead of the worker, eliminating error, improve the output and reduce the cost.

Instead Of The Workers

In the production process, the operator just as porters, the intelligent furniture cutting equipment can realize automatic paste barcode, automatic feeding, drilling, slotting, cutting, automatic uploading, automatic retrieval processes for cutting side hole, slot on the back, back hole, the whole process don’t need human judgment, automatic processing, get rid of the dependence of woodworking professional and technical workers.

Besides, Automatic feeding machine instead of the traditional push table saw or precision saw, to prevent the occurrence of work-related injuries, the health of employees is guaranteed.

Eliminating Error

The working path is automatically generated by the software. Through the intelligent design software to split single 3D modeling,it can realize the real effect of map rendering. Customized furniture shape and size at a glance. After the automatic assembly generated a single panel report and hardware statements, and outputs all sheet drawing format (DXF format drawings belonging to a common format, it can be open in all the cnc router software), each piece of plate holes, slots are automatically generated. Through the optimization by the automatic layout software to optimize the layout and generate the processing path (NC program), to maximize use of raw materials.

Improve The Output Value

Intelligent nesting CNC machine complete can mass production of customized furniture, semi-finished products processing can be clearly distinguished, not easy to confuse.

Reduce Costs

Intelligent CNC nesting machine can reduce labor, improve the utilization of raw materials, greatly reduce production costs.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.