Stone CNC Machine for Marble, Granite and Quartz

CNC stone machines are widely used in the fabrication of granite kitchen countertops. These machines use computer programs to control the cutting and shaping of granite slabs with precision. The process typically involves cutting, shaping, and polishing the granite to create a custom countertop that fits a specific kitchen layout. CNC machines offer high accuracy and efficiency in granite countertop fabrication, resulting in a polished and attractive final product.

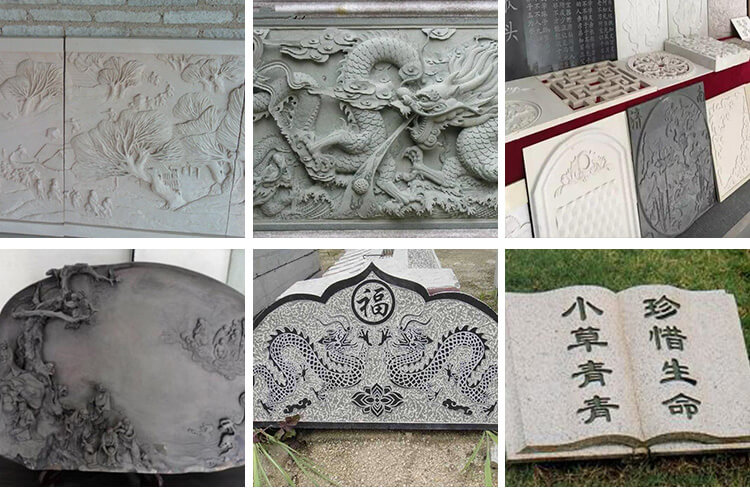

Stone CNC router is a computer numerical controlled machine tool used for CNC stone carving, CNC stone engraving, and CNC stone cutting. The stone router machine can complete functions of engraving, carving, cutting, milling, and polishing of granite, quartz, marble, tombstone, ceramic tiles, and other artificial stones. Therefore, we also call it marble CNC router, marble carving machine, granite CNC router, CNC granite cutting machine for sale, quartz stone machine, etc. Our stone CNC machine for sale includes 3 axis stone router, 4 axis stone CNC engraving machine, and 5 axis stone CNC machine. In addition, machine specifications of the CNC router machine for stone can be customized to meet your specific processing requirements and demands.

Features and Advantages of Stone CNC Machine:

1. The stone CNC machine bed is welded by the thick wall steel seamless tube, high temperature tempering treatment, high rigidity, bearing strength better .

2. Dual stepper motor drive for Y-axis, moving stably.

3. DSP control with good software compatibility, suitable for Type3, Artcam, Castmate, Ucanam.

4. Constant spindle motor 5.5 KW power, strong cutting strength, high efficiency.5. High precision rack transmission, high speed.

6. Imported linear square guide way, double row four row slider, high precision, long life time.

7. Well selected electrical accessory, let the failure rate to the minimum.

8. With water and automatic water supply and cooling system.

9. Dustproof and waterproof design, better to protect the machine driving part.

Application of the stone CNC machine

The stone CNC machine is widely used in construction, decoration, inscription technology, stone carving art, models, kitchen and bathroom countertop, handicrafts and other industries. A stone engraving machine can engrave multiple stones. For example, granite, marble, sandstone slab, limestone, ceramic tile, quartz, and various artificial stones. The granite carving machine can complete relief engraving, letters and patterns engraving, hollow-out engraving, cutting, milling, and other processes.

The quartz stone CNC machining center integrates the functions of cutting, edging, drilling, polishing, chamfering, and engraving. It mainly processes the quartz stone, marble, granite, artificial stone, slate, and other stone materials. The CNC quartz and marble cutting machine is widely used in forming and polishing kitchen countertops, bathroom countertops, stone coffee tables, special-shaped bar counters, basin holes and arc water blocking.

CNC Tombstone Engraving Machine

CNC Technology: These machines are equipped with Computer Numerical Control (CNC) systems. CNC technology enables automated and highly precise engraving by following digital designs and instructions programmed into the machine’s software.

Materials: CNC tombstone engraving machines are primarily used for engraving on various types of stone, including granite, marble, and other natural stones commonly used in tombstones and monuments.

Applications:

Text Engraving: They are used for engraving names, dates, epitaphs, and other text onto tombstones.

Graphics and Designs: These machines can also engrave intricate graphics, patterns, and designs, allowing for highly customized and personalized memorial markers.

Photographic Engraving: Some advanced CNC tombstone engraving machines can even engrave photographs onto stone surfaces.

Precision and Detail: CNC machines offer high precision and detail in engraving, ensuring that the inscriptions and designs on tombstones are clear, sharp, and long-lasting.

Efficiency: Compared to manual engraving methods, CNC tombstone engraving machines are more efficient and can complete engraving tasks quickly, reducing labor costs and production time.

Customization: They enable customers to create unique and personalized memorials for their loved ones, incorporating specific designs and sentiments.

Maintenance: Regular maintenance and calibration are necessary to ensure the machine continues to produce high-quality engravings. Proper care can extend the machine’s lifespan and maintain engraving accuracy.

Safety: Operators must follow safety protocols when working with CNC tombstone engraving machines, including wearing protective gear and ensuring proper ventilation when working with stone dust generated during engraving.

These machines are commonly used by monument companies, stone engraving businesses, and cemeteries to create personalized and lasting tributes to individuals who have passed away. The CNC technology ensures that the engravings are precise and of high quality, preserving the memory of loved ones for generations.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.