Cabinet Making CNC Machine

A CNC Machine for cabinet making is a specialized tool that automates the cutting, drilling, and shaping of cabinet components. By using computer-controlled instructions, these machines execute precise operations, ensuring consistent and accurate results every time.

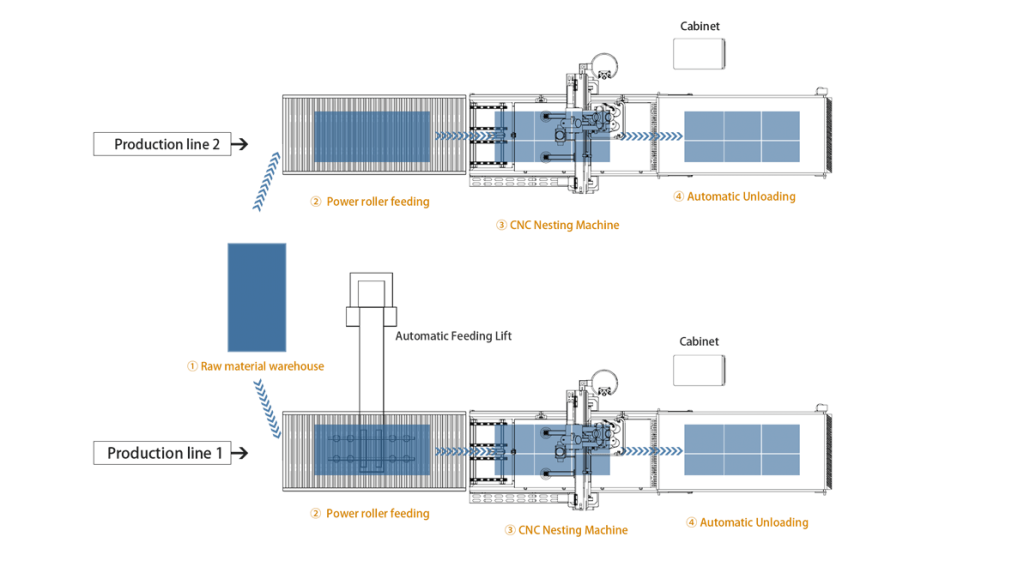

This Automatic Cabinet Making CNC Machine is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. This CNC machine is used majorly in the production of cabinets, closets, and custom furniture.

Automatic Feeding Lift For Custom Made

Handling large furniture panels can be a difficult and time-consuming task, and assembling this automatic feeding device can greatly improve work efficiency.

Advantages of Full Automatic CNC Machine for cabinet making

1. Increase 10% material usage.

2. Reduce the dependence of the technical workers.

3. Decrease of sorting procedure and sorting error.

4. Save both time and labour for complicated workpiece processing.

5. It can also groove and drill.

6. Improve the product quality and the efficiency.

7. Optimize technology procedure, reduce the production cost.

Applications of Cabinet Making CNC Machine

1. Furniture Industries

Cabinet doors, wooden doors, solid woods, plates, antique furniture, doors, windows, tables and chairs.

2. Decoration Industries

Screens, wave boards, large-size wall hangings, advertising boards and sign making.

3. Arts & Crafts Industries

Achieveing effects of exquisite patterns and characters on artificial stones, woods, bamboos, marbles, organic boards, double-color boards and so on.

4. Processing Material

Carving, milling and cutting for acrylic, PVC, density boards, artificial stones, organic glass, plastics and soft metal sheets such as copper and aluminum.

Future Trends in CNC Cabinet Making

Automation and Robotics

The integration of automation and robotics in CNC machines is a growing trend. Automated material handling, tool changing, and even robotic arms for complex operations are becoming more common, further enhancing efficiency and precision.

Advanced Materials

As new materials are developed, CNC machines are evolving to accommodate them. From composite materials to advanced wood products, the ability to work with a broader range of materials opens up new possibilities for cabinet making.

Smart Technology

The incorporation of smart technology, such as IoT (Internet of Things) and AI (Artificial Intelligence), is transforming CNC machines. These technologies enable real-time monitoring, predictive maintenance, and optimized performance, making the machines more intelligent and efficient.

1. What is a CNC machine used for in cabinet making?

A CNC machine is used for cutting, drilling, and shaping cabinet components with precision and efficiency. It automates complex operations, ensuring consistent and accurate results in cabinet production.

2. How does a CNC machine improve efficiency in cabinet making?

CNC machines automate tasks such as cutting, drilling, and shaping, significantly increasing production speed. Features such as automated tool changes and material optimization further enhance efficiency, allowing cabinet makers to complete projects faster.

3. What should I consider when choosing a CNC machine for cabinet making?

When choosing a CNC machine for cabinet making, consider your production needs, machine specifications, software compatibility, and manufacturer support. Evaluate factors such as cutting speed, spindle power, tool capacity, and worktable size to ensure the machine meets your requirements.

4. How do I maintain a CNC machine for cabinet making?

To maintain a CNC machine for cabinet making, regularly clean the machine, lubricate moving parts, inspect and calibrate components, and keep the software up to date. Proper maintenance ensures optimal performance and extends the machine’s lifespan.

5. What are the future trends in CNC cabinet making?

Future trends in CNC cabinet making include the integration of automation and robotics, the ability to work with advanced materials, and the incorporation of smart technology such as IoT and AI. These advancements enhance efficiency, precision, and versatility in cabinet production.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.