In the realm of woodworking, the advent of the computerized router has transformed the craft into a blend of art and technology. These advanced machines, also known as CNC (Computer Numerical Control) routers, bring precision, efficiency, and versatility to woodworking projects, making them indispensable tools for both professionals and hobbyists.

Computerized Router Woodworking

A computerized router, or CNC router, is a machine that is controlled by a computer to cut, carve, and shape wood and other materials. The term “CNC” stands for Computer Numerical Control, indicating that the machine’s movements are precisely directed by a computer program. This technology allows for intricate and accurate designs, making it ideal for detailed woodworking projects.

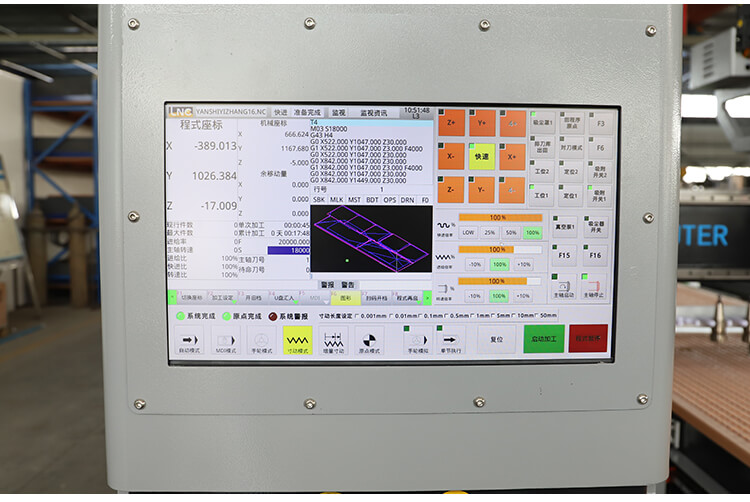

The process begins with the creation of a digital design, typically using CAD (Computer-Aided Design) software. This design is then converted into a G-code, a language that CNC machines understand. The G-code instructs the router on how to move and where to cut. When the machine is activated, the router bit follows the programmed path, carving out the design with precision.

Benefits of Using a Computerized Router

Precision and Accuracy

One of the most significant advantages of using a computerized router is its precision. The computer-controlled movements ensure that each cut is accurate, reducing the margin of error and minimizing material waste.

Versatility

CNC routers can work with a variety of materials, including wood, plastic, and composites. This versatility makes them suitable for a wide range of applications, from furniture making to intricate carvings.

Cost-Effectiveness

While the initial investment in a CNC router can be substantial, the long-term benefits often outweigh the costs. The precision and efficiency of these machines reduce material waste and labor costs, leading to significant savings over time.

Ease of Use

Modern CNC routers are designed with user-friendly interfaces, making them accessible to both professionals and hobbyists. Many models come with pre-installed software and intuitive controls, simplifying the woodworking process.

Applications of Computerized Router Woodworking

Furniture Making

In the furniture industry, CNC routers are used to produce parts and components with high precision. They are commonly employed to cut and shape wood for tables, chairs, cabinets, and other furniture pieces.

Artistic Woodwork

Artists and craftsmen utilize CNC routers to create intricate designs and sculptures. The precision of these machines allows for detailed and complex patterns that would be challenging to achieve with traditional woodworking methods.

Sign Making

CNC routers are widely used in the sign-making industry to carve letters and designs into wood and other materials. The ability to produce precise and consistent results makes them ideal for creating professional-quality signs.

Prototyping

Engineers and designers often use CNC routers to create prototypes of new products. The ability to quickly and accurately produce parts enables rapid iteration and testing, speeding up the development process.

Custom Woodworking

For custom woodworking projects, CNC routers offer the flexibility to create unique and personalized designs. From custom cabinetry to bespoke furniture, these machines enable woodworkers to bring their creative visions to life.

CNC Routers for Woodworking

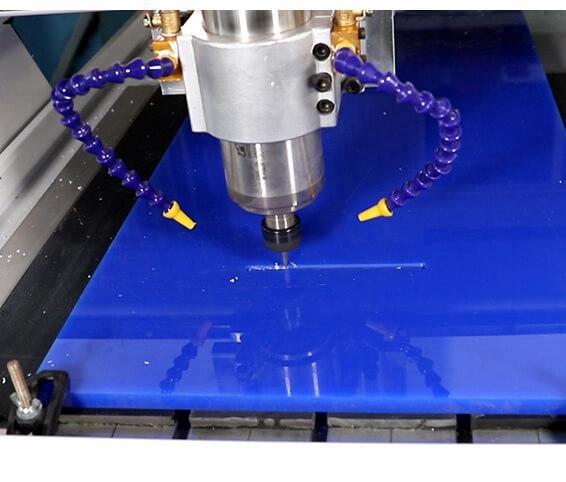

CNC Router Machine for Woodworking is the perfect computer-controlled machine for cutting and engraving wood, acrylic, MDF, plastic, marble, rubber, epoxy resin, glass, foam, crystal and other materials. It typically falls into two types, ball screw-driven and rack & pinion-driven. More configuration options include carousel or linear ATC, double platforms, auto loading & unloading platforms, auto labeling platform, drilling head, etc.

Of course, if you have other machining requirements such as three-dimensional work pieces, curved surface machining of complex work pieces, we also have CNC equipment such as 4-axis CNC machine, rotary axis CNC machine, ATC CNC machine and multi-head engraving machine for you to choose.

We offers a variety of CNC for woodworking with many standard configurations for you to choose from. For instance, ATC CNC machines, 4 axis CNC machines, 3 axis CNC machines, multi-head CNC machines, mini CNC machines, best hobby CNC machines, stone CNC machines, and EPS CNC machines. In terms of worktable size, the best CNC router falls into 2×4, 4×4, 5×10, 4×8 CNC router, etc.

Type of Computerized Router Woodworking

Choose a CNC machine that suits your specific needs and budget. Take the time to research different brands and models, considering their features, performance, and pricing. Make a wise decision based on your woodworking project requirements.

Here is our collection of most popular cnc routers for woodworking, from single-spindle to multi-spindle kits, from small footprint to large format tables, from desktop to gantry styles, from hobby to industrial models, from primary 3 axis to professional 5 axis, from entry-level for beginners to high-end ATC series for experts, all types of CNC wood routers are available. In addition, a variety of customization options and add-ons are also available to personalize your machine tools. Just discover what you need, plan your budget, compare features and costs, find and buy the best one to start or upgrade your woodworking business.

3-Axis Computerized Router Woodworking

The working principle of best CNC Woodworking Machine is as following: The woodworking CNC machine uses a computer to realize digital program control, and executes the control program stored in advance through the computer to realize the machine’s motion control, timing, logic and other functions, so as to control the equipment to complete the automatic woodworking. Then the control computer converts this code into a signal that controls the movement of the woodworking engraving machine’s driving system. The drive system makes the spindle moving along the XYZ axis, and working according to the G-code command. In short, the operator creates a design by a CAD software, and uses a CAM software to make generate the G-code, then the wood CNC router working according to the G-code command.

4 axis Computerized Router Woodworking

4 Axis CNC woodworking routers machine refers to a CNC machine whose processing path include X, Y, Z, and A axis. And we are going to talk about a 4 axis machine whose spindle can swing left and right. Because the spindle of this type of CNC can swing left and right, the spindle can approach the work piece from multiple different angles and efficiently process three effective processing surfaces. This CNC machine can realize not only the plane engraving, but also the 3d carving of irregular work pieces. And this type of wood CNC machine is suitable for common work piece, three-dimensional work piece, complex work piece and irregular graphics processing.

In addition, this type of cnc woodworking machine makes full use of the geometric configuration of the tool, controls the angle of the force, reduces the vibration of the force, prolongs the life of the tool, enhances the stability of the processing, and improves the processing accuracy. With the advantages of complete functions, wide processing range and high processing accuracy, more and more users choose the 4 axis machines for 3D Wood Carving. If you have similar three-dimensional work pieces, this CNC Wood Router will be your ideal choice.

Key Considerations When Choosing a Computerized Router

Cutting Area

The cutting area of a CNC router refers to the maximum size of the material it can accommodate. When selecting a machine, it’s essential to consider the types of projects you will be working on to ensure the router meets your needs.

Spindle Power

The spindle power of a CNC router determines its cutting capabilities. Higher spindle power allows the machine to cut through thicker and harder materials. Consider the types of materials you will be working with when choosing a router with the appropriate spindle power.

Software Compatibility

The software compatibility of a CNC router is another crucial factor to consider. Ensure that the machine is compatible with the CAD software you use and that it can easily convert designs into G-code.

Portability

For those who need to move their router between job sites, portability is an important consideration. Look for models that are lightweight and come with features such as carrying handles or wheels for easy transportation.

Price

The price of a CNC router can vary significantly based on its features and capabilities. It’s essential to balance your budget with the machine’s performance and ensure that you are getting the best value for your investment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.