3d CNC Foam Cutting Machine

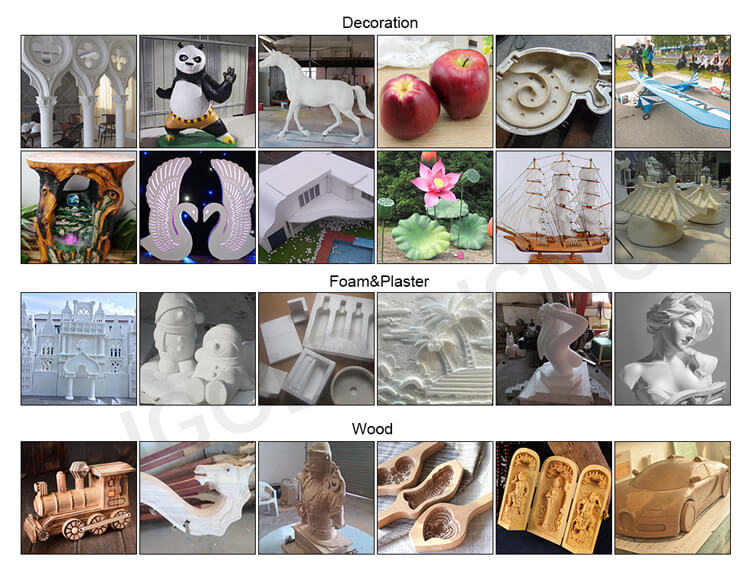

EPS Foam CNC Router is one kind of foam CNC machines, it is mainly working as a CNC foam cutter for styrofoam carving, it has a big working dimension, does a good job in carving or cutting of large scale workpieces in different materials, such as wood, aluminum, styrofoam, but not for steel, iron, etc. It is widely used to process and carve wood and styrofoam automotive, ship or other molds, and GRG or GRC decorations, and architecture models.

3d Cnc Foam Cutting Machine Video

CNC Machining Center Parameter

| Model | iGW-MC-2060 |

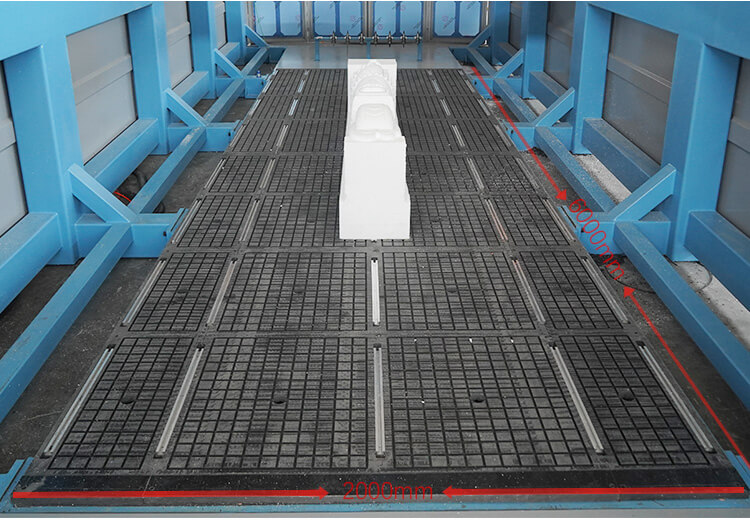

| Working area | 2000*6000*1100mm |

| Spindle | China HQD 9kw atc air cooling spindle + swing 180 degree |

| Inverter | Fuling |

| Motor | Japan Yaskawa 850W servo motor |

| Driver | Japan Yaskawa 1kw servo driver |

| Control System | Syntec 6MB control system + hand wheel |

| Table | Vacuum & T-slot table with 7.5kw air vacuum pump |

| Transmission | XY helical rack, Z Taiwan TBI ball screw |

| Guide rail | Taiwan linear guide |

| Ball screw | Z TBI ball screw |

| Body | Thick steel tube Welded body |

| Beam | Steel beam |

| Columns | Steel columns |

| Control box | Independent control box |

| Colour | Custom made |

| Lubrication | Automatic oiling |

| Tool Setting | Automatic Tool Calibration Sensor |

| Dust collector | Double bag dust collector |

| Voltage | 3 Phase/380V/50HZ |

| Rotary axis | Optional part |

Structure

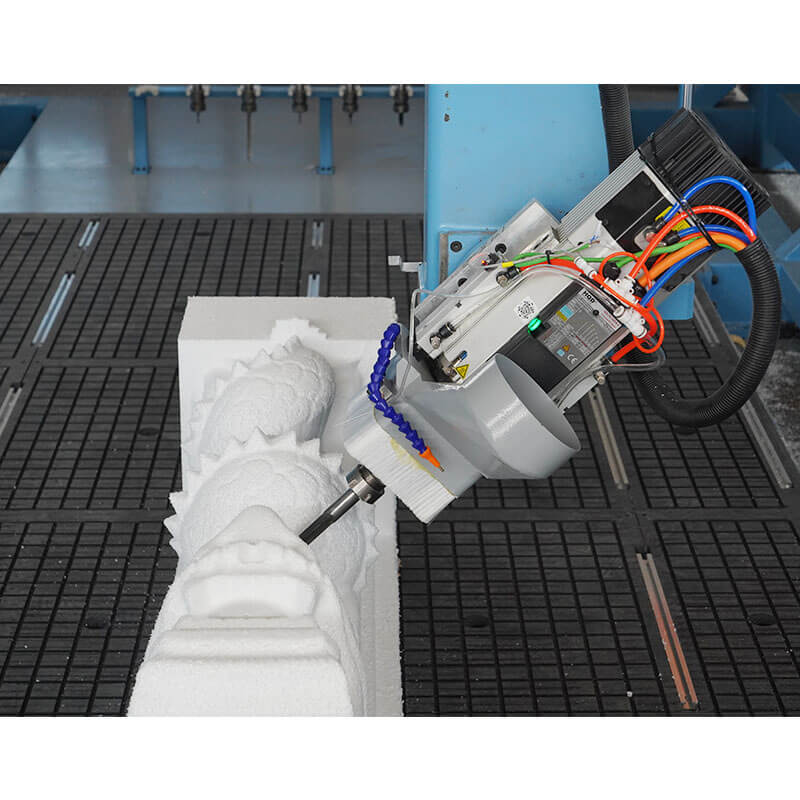

This is an upgraded foam CNC router which is equipped with HSD air cooling spindle with imported bearing, it has many advantages like long service life, low noise, and strong cutting ability. Besides that With the function of linear automatic tool changer, it make the whole processing more time-saving and more efficient. Therefore it may be your better choice to process some foam products.

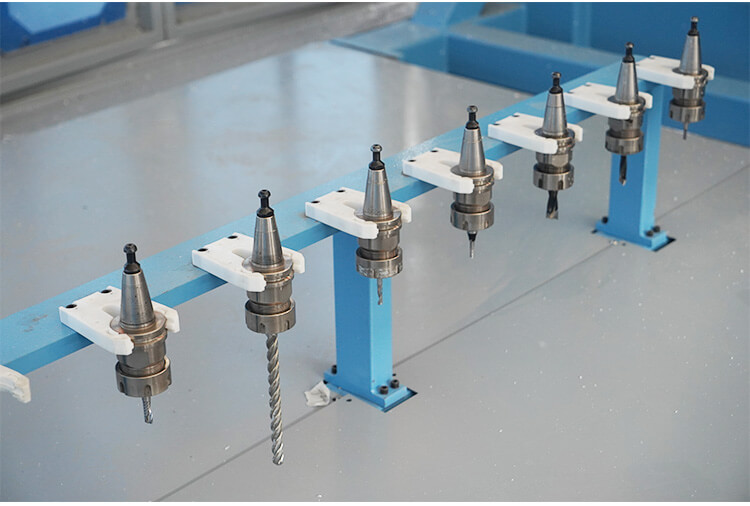

Linear Automatic Tool Changer

With the function of linear automatic tool changer, it make the whole processing more time-saving and more efficient.

Air Cooling Spindle

Equipped with HSD air cooling spindle with imported bearing, it has many advantages like long service life, low noise, and strong cutting ability.

Worktable Optioned

There are many choices of table size: 1300*2500mm, 1500*300mm, 2000*4000mm, (we can customize the size according to your needs)

The cast iron worktable with the fixture is the standard worktable.

The vac-sorb worktable with T-slot can be optioned.

Control System Optioned

Taiwan LNC system is the standard system.

Taiwan SYNTEC system, Germany SIEMENS system can be optioned.

Eps CNC Router 4 Axis Machining Centre

Mold industry: casting mold, automobile, ship, yacht, aviation industry, rail transportation etc.

Musical instruments: large 3D curved surface and shape processing.

Applicable materials: wood, EPS, other non-metal carbon mixed compound, etc.

Contact Us Today to Get Price!

4 axis CNC router is an automatic computer-controlled machine tool whose spindle rotates 180° along the X-axis or the Y-axis to do 3D arc milling and cutting, which is based on the ordinary 3 axis machine tool.

4th axis CNC router is an automated machine tool kit with computer numerical controller for relief carving and sheet cutting, as well as adding the fourth axis (rotary axis) for 3D cylinders milling.

In addition, the 4-axis CNC machine is divided into four-axis three-linkage and four-linkagel, not to say that the rotation is added, it is a four-axis linkage machine tool, and a computer-controlled system with a rotating axis and a four-axis linkage can be called as a real 4 axis CNC machine. Because of the rotation movement of the 4th rotary axis, 3D machining of cylindrical, arc, and circular surfaces is realized. A real 4-axis machine tool can cut wood, foam, stone, white marble, human body, Buddha statues, sculptures, handicrafts, furniture. 4-axis is refer to X-Y-Z-A, X-Y-Z-B or X-Y-Z-C, 4 axis are linked, the four axis can work at the same time. If the machine has only three feed axes (X, Y, Z), the Y-axis can be manually replaced with a rotating axis, and it can only be three-axis linkage at most. This is a 4th axis CNC machine, and it is also the usual fake four axis. In terms of use, it can process planes, reliefs, and cylinders. If the machine has four feed axes (X, Y, Z, A), it can be processed with four-axis linkage, and can process planes, reliefs, cylinders, non-standard three-dimensional patterns, and corners of 3D patterns.

Hand-tool working greatly affects the efficiency and quality of mold making. CNCs have the advantages of uniform margin, fast processing speed, and high processing quality, this CNC foam cutting machine is widely used in many industries, which not only improves the quality of mold castings but also shortens the mold production cycle.

- Adopting original cross-beam triangle balanced guide rail structure and Z-axis balance auxiliary device, it can ensure fast and stable processing of multi-curved surfaces.

- It adopts Taiwan’s integrated operating system, which is easy to operate and powerful, and has online simulation and online monitoring functions to ensure safe and efficient processing.

- Processing size can be customized according to processing needs. And whose Z-axis travel can be up to 2.2 meters and this machine can be upgraded to a 5 axis CNC machine.

- Adopting automatic oil lubrication system, it is easier to operate and maintain during the processing.

- Adopting the high-power servo drive system in conjunction with the top accessories such as the Italian spindle to make the equipment stable and durable.

- Intelligent processing cross-border protection function can prevent mechanical collision caused by excessive design file processing.

- Diversified control can separately control the processing speed, idling speed, and cutting speed, which greatly improves the quality and processing efficiency of processed products.

- With the functions of continuous break point carving, power recovery, processing time prediction, it can be handy regardless of vigorous cutting or fine carving.

- Extremely humanized design combined with ergonomic design makes your operation easier.

- Regardless of whether the operation panel is highly designed or modularized, it is to make you have a better user experience.