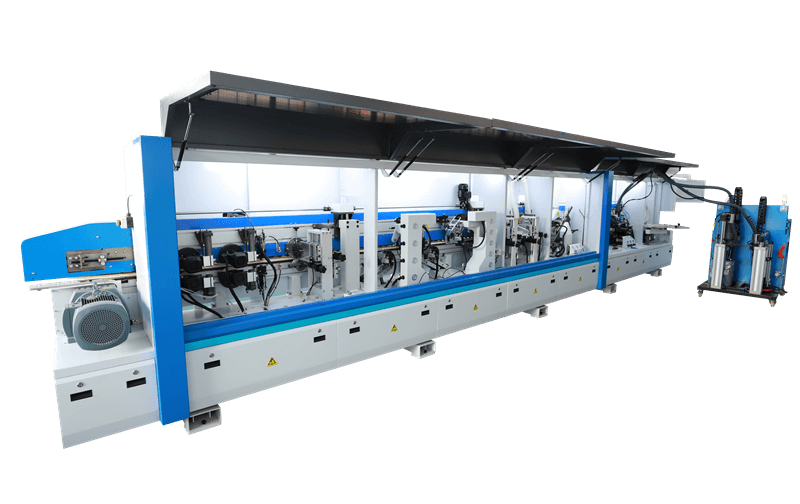

Edge Banding Machine for Wood and Aluminum

Aluminum wood edge banding machine is a kind of high efficiency equipment specially used for aluminum honeycomb panel and various wood panel edge processing.

Aluminum wood edge sealing machine has high precision edge sealing function, it can accurately fit the edge strip on the edge of the plate, the edge strip and the edge of the plate are very high, the error is very small, and can quickly seal a large number of plates.

Suitable for a variety of materials edge processing, including aluminum honeycomb furniture, PTP, medium density fiberboard, joinery board, solid wood, particle board, polymer door panels, plywood, etc., aluminum wood edge sealing machine with its efficient, stable and flexible characteristics, has become one of the indispensable equipment in the furniture manufacturing industry, especially suitable for the pursuit of high quality and efficient furniture manufacturers.

CNC Furniture Making Video

Processing process

Beam press feeding → baking lamp preheating – board pre-milling (diamond 4+4 large angle pre-milling cutter) → baking lamp→ sixth-generation new sealing PUR special glue pot dual-color glue machine without cleaning (easy to clean, full Teflon coating, new flow channel design for convenient glue cleaning) → conventional pressing → first set of extended belt non-powered vertical shaft pressing (independent design) → front and back trimming (with pressure relief function, better for thin aluminum skin) → dual-wheel pressing → upper and lower rough trimming (upper and lower diamond four-tooth) → upper and lower fine trimming (upper and lower diamond six-tooth) → four-head tracking chamfering → upper and lower edge scraping (diamond scraper with directional blowing) – flexible edge scraping – wire breaking – post-cleaning device →1 upper and lower polishing→ 2 upper and lower polishing.

CNC Furniture Production Line Parameter

| Dimension | 11500*950*1680MM |

| Weight | 3.8T |

| Gross power | 24KW |

| Feed rate | 12-15-18m/min |

| Edge band thickness | 0.3-3mm |

| Sheet thickness | 10-60mm |

| Sheet length | ≥150mm |

| Sheet width | ≥60mm(45MM narrow side can be customized) |

| Working pressure | 0.6-0.8MPa |

| The minimum board size. | 300(L)*60(W) |

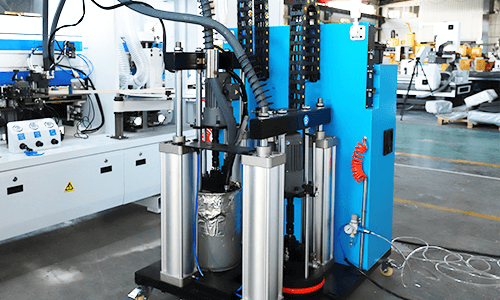

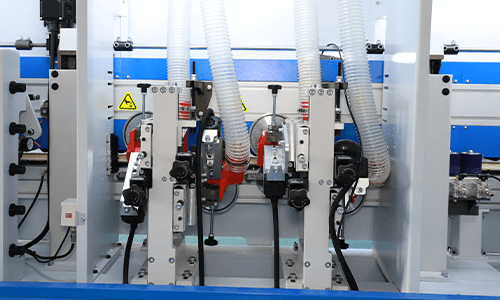

Two-color PUR glue machine

The two-color glue machine is used to optimize the edge sealing effect and achieve better surface treatment by alternately applying dark and light-colored special glue.

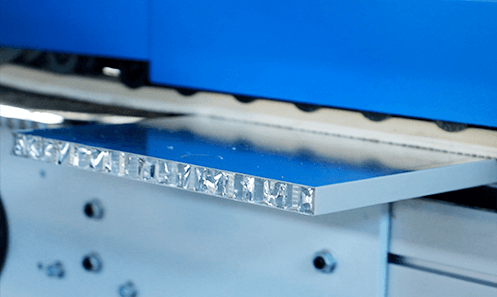

All aluminum pre-milling cutter head

For the special composite material of all aluminum honeycomb board, specially customized diamond pre-milling cutter, from the number and Angle of diamond blade, make it more durable, smooth cutting, so as to achieve better edge sealing effect.

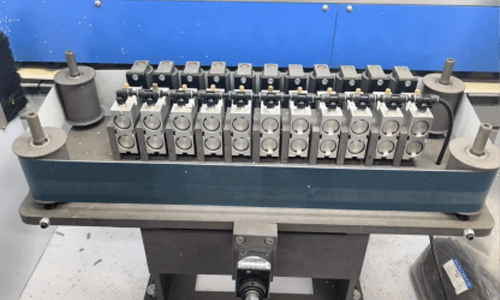

Pressing mechanism

Independently developed for the honeycomb aluminum plate pressing mechanism, by the multi-axis roller with independent cylinder, the outer ring belt fitted hybrid pressing. The precision screw with counter to adjust the stroke, soft outside and hard inside, suitable for honeycomb plate, no damage to the aluminum plate does not roll, side tape bonding better firm.

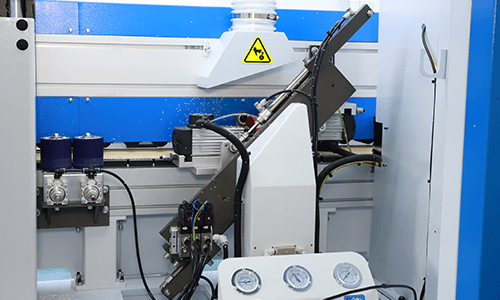

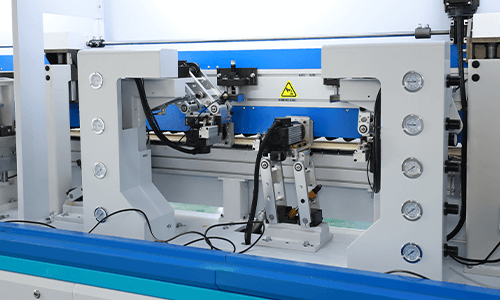

Low pressure flexible flush

For the gas path and program action of the head parts are subdivided and optimized to make it softer, aluminum honeycomb panel can be relatively thinner, allowing customers to reduce material cost space, more competitive in the market, and double wheel pressing makes it adhesive.

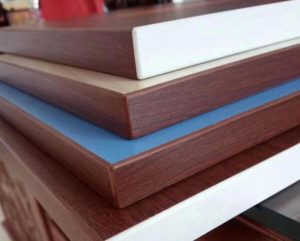

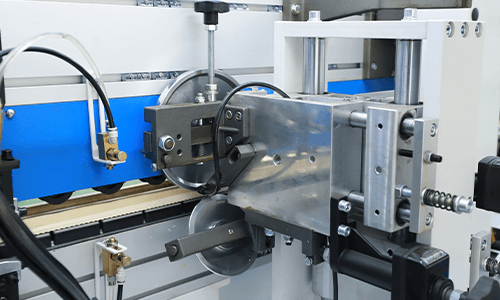

Rough repair fine repair

It is used to repair the excess edge sealing material after rough repair of the upper and lower parts of the processed plate sealing band, and make the arc natural transition between the plate and the sealing band.

Four head tracking chamfer

For the special composite material of all aluminum honeycomb panel, the optimization of the tracking gas path and the redesign of the imitation parts make it reach the true aluminum wood one, perfect switching, and the tracking chamfer is smooth and full without adjustment.

Pressing mechanism

Independently developed for the honeycomb aluminum plate pressing mechanism, by the multi-axis roller with independent cylinder, the outer ring belt fitted hybrid pressing. The precision screw with counter to adjust the stroke, soft outside and hard inside, suitable for honeycomb plate, no damage to the aluminum plate does not roll, side tape bonding better firm.

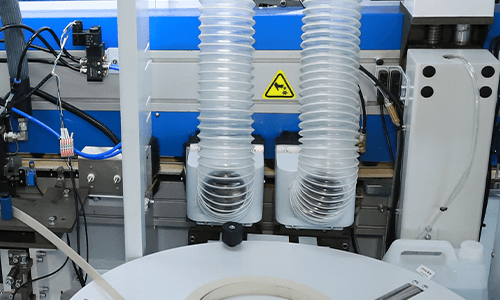

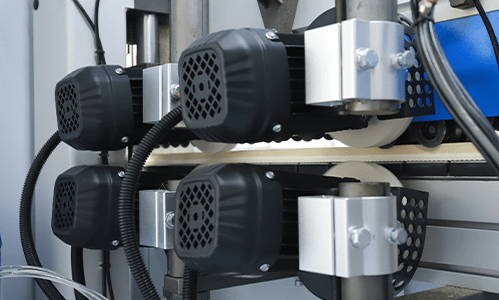

Double polished with guard

Add a shield to each motor to reduce the ribbon wrapped around the motor shaft after polishing to avoid causing the motor to burn out.

Key Features of Aluminum-Wood Edge Banding Machine

1.Milling flat the edges and residues on the cut surface of the board, making the glue coating more even and the glue line thinner.

2.Use PUR glue, precise glue supply, fully enclosed glue delivery, glue coating is thinner, more delicate and even.

3.The steel wheel + rubber wheel + belt combination, repeated pressing mode, strongly presses the edge band to make it smoother, improve the edge quality and appearance, and avoid gaps and warping.

4.Rough trimming + fine trimming, trim off the excess edge banding material on the upper and lower edges of the processed board to ensure that the upper and lower parts of the trimmed board are flat and smooth.

Edge Banding Machine Application

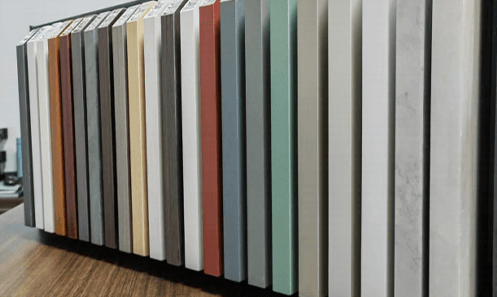

Aluminum wood edge banding machine is suitable for a variety of materials edge processing, including aluminum honeycomb furniture, PTP, MDF, joinery board, solid wood, particle board, polymer door board, plywood and so on. This versatility allows the equipment to adapt to the needs of different furniture manufacturing.

Contact Us Today to Get Price!

It is suitable for edge banding of solid wood board, polymer door panel, plywood, PTP, medium density fiberboard and other boards.

Any edge band with the thickness between 0.4mm to 2mm can be used to band edges.

Our automatic edge banding machines have rough trimming, fine trimming, and polishing functions. All these functions help to trim and polish the edges to remove the exceeded glue.

According to the degree of automation, the edge banding machine mainly includes the manual edge bander, semi automatic edge banding machine, and automatic edge banding machine. They can achieve different functions and have distinct banding effects.

The main difference between fully automatic and semi-automatic lies in the processing functions. Semi-automatic edge banders can realize such functions as gluing, edge banding, upper and lower trimming, and polishing.But the fully automatic edge banding machine has the functions of pre-milling, gluing, edge banding, trimming, contour tracking, scraping, polishing, and so on. The automatic edge bander machine has gradually replaced the semi-auto type due to its high cost-performance ratio.

From the shape of the edge banding, the banding machine can be divided into the straight edge banding machine, straight and curved edge banding machine, and bevel edge bander machine.