Edge Banding Machine

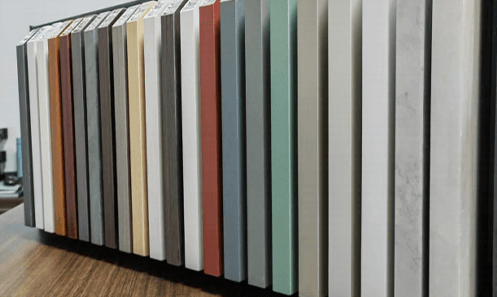

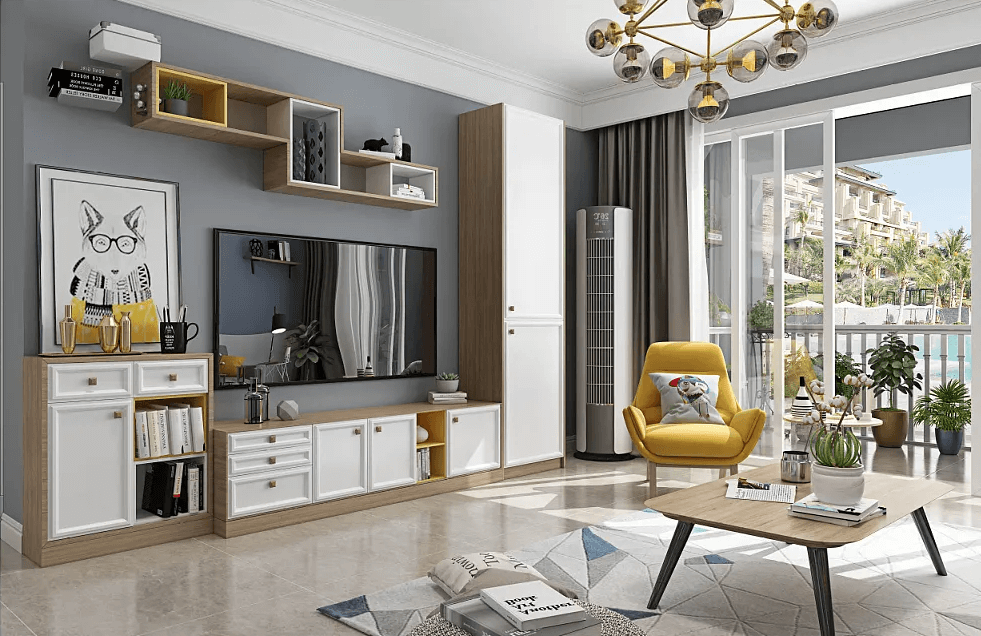

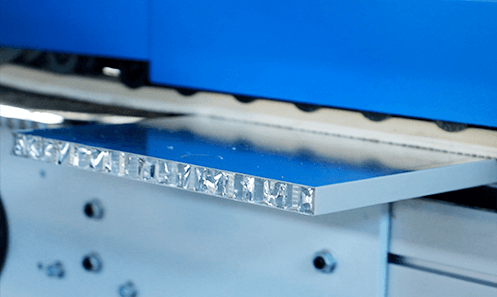

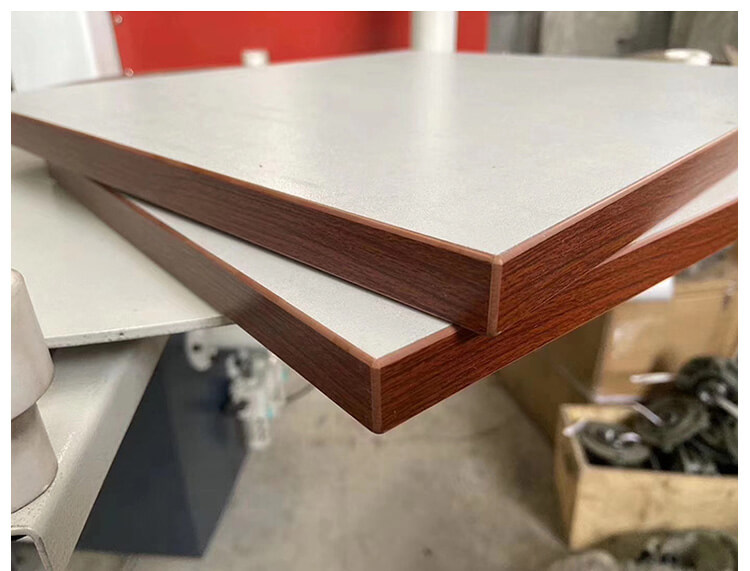

The edge banding machine, is used to band the straight and curved panel edges for custom furniture production. A woodworking edge banding machine falls into the manual edge banding machine and the auto edge banding machine, specially designed for shops and companies looking for efficient and precise edge banding service and solutions.

Functions of the automatic edge banding machine include pre-milling, gluing, banding, end cutting, rough and fine trimming, corner rounding, scraping, polishing, etc. The manual edge bander and semi automatic edge banding machine can also realize straight and curve cabinet edge banding.