Double Table Processing 4 Axis CNC Router

4 Axis CNC Router Machine Video

Double table processing, high efficiency

China HQD 9kw atc air cooling spindle + swing 180 degree

Disc tool changer magazine

Taiwan Syntec control system ,With the handwheel

4 Axis Router Wood Carving Machine Parameter

| Model | iGW-1230 |

| Working area | 1200x800x500mm |

| Transmission | X axis: Taiwan grinding rack,YZ axis: Taiwan TBI screw |

| Reducer | JAPAN SHIMPO |

| Servo motor | Taiwan Syntec AC servo motor |

| Control system | Taiwan Syntec control system |

| Spindle | 9KW HQD spindle and rotating 180° |

| Inverter | Taiwan Delta 11kw |

| Guide rails | Taiwan Hinwin 30mm |

| Table structure | Vacuum table with Vacuum pump |

| Tools magazine | Disc tool changer magazine |

| Tool senior | YES |

| Lubrication | Automatic |

| Dust collector | 5.5kw |

We offer customized services according to your requests such as the working area and specifications.

Applications Of 4 Axis CNC Router Machine

Suitable for large lines in the solid wood industry and mold industry

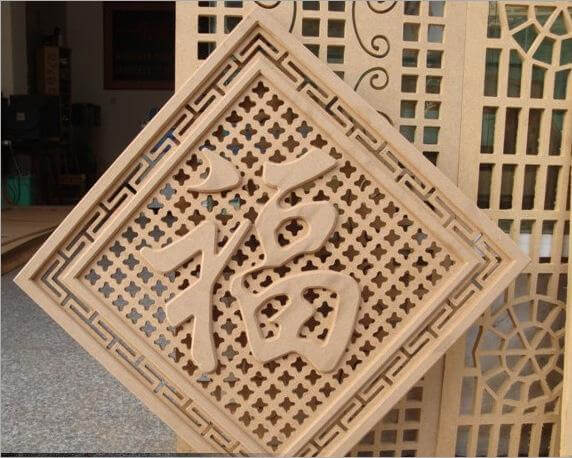

Wooden furniture industry: wave boards, fine patterns, antique furniture, wooden doors, screens, craft window sashes, composite doors, cabinet doors, interior doors, sofa legs, headboards, etc.

Advertising industry: Advertising recognition, sigh production, acrylic carving and cutting, crystal character production, sandblasting molding and other advertising material derivatives production.

Mold industry: sculptures of metal molds such as copper, aluminum, iron, and sculptures of artificial marble, sand, plastic cloth, PVC pipes, wooden boards and other non-metal molds.

4 Axis CNC Router Features

1.Adopting Taiwan’s new generation control system, silver guide rail, Yaskawa servo and driver, high-power tool change spindle and two movable worktables, high processing accuracy and high performance.

2.The spindle can be rotated ±90°, which can realize side milling, drilling, cutting, and keying. It is very suitable for processing various curved surfaces with high precision and fast speed, which fully meets the needs of engraving.

3.The vacuum workbench can be used to fix small materials with clamps, and the processing is diversified.

Contact Us Today to Get Price!

A 4 axis CNC router operates on the X, Y, and Z axes like a 3-axis machine, but it also includes rotation around the X-axis, which is called the A-axis. This is the 4th axis that’s added to our machining process. In most cases, the workpiece will be rotated to allow for cutting to occur around the B-axis. Because the spindle of this type of CNC can swing left and right, the spindle can approach the work piece from multiple different angles and efficiently process three effective processing surfaces, the three-dimensional machining of cylindrical, curved and circular surfaces is realized. These four Axis CNC machines can realize not only the plane engraving but also the 3d carving of irregular workpieces. And this type of wood CNC machine is suitable for the common workpiece, three-dimensional work piece, complex work piece, and irregular graphics processing.

(4 Axis CNC router machine can realize the processing of three-dimensional work pieces such as Dragon pillar, Guanyin statue, Buddha statue, Roman column, gourd, and so on. And it can be also widely used in three-dimensional wave board processing, cabinet doors, solid wood doors, craft doors, paint-free doors, screens, craft window processing, shoe polishers, game cabinets, and panels, mahjong tables, computer tables, and panel furniture products’ auxiliary processing. Moreover, it can be widely used in casting molds, foam molds, automotive molds, train molds, aviation molds, ship molds, paraffin molds, and more applications.)

This type of CNC engraving machine makes full use of the geometric configuration of the tool, controls the angle of the force, reduces the vibration of the force, prolongs the life of the tool, enhances the stability of the processing, and improves the processing accuracy. With the advantages of complete functions, wide processing range, and high processing accuracy, more and more users choose the 4 axis CNC router machines for 3D Wood carving. If you have similar three-dimensional workpieces, this CNC Wood Router will be your ideal choice.

In addition to the most common three-axis CNC Router, there are now four-axis three-linkage CNC Router and four-axis four-linkage CNC Router, which are what we say as the real four-axis and fake four-axis engraving machines. For customers who want to do both three-dimensional materials and flat materials, they don’t know what they can do and what are the differences, and they are entangled in their own requirements to choose which one is suitable. Then IGOLDENCNC is here to give you a detailed answer to distinguish between true four-axis and fake four-axis, to help you find a machine that suits you.

1. The four-axis three-linked movement mode is X (beam), Y (table), Z (carving spindle), and C (rotating axis). Three of the four axes can move at the same time, either X, Y, C or X, Z, C. In other words, table Y and the rotation axis C can only be transformed into each other, but they cannot move at the same time. That is to say, the three axes are really moving, that is to say, the engraving machine only rotates around the axis when engraving. The four-axis four-linkage movement mode is: X, Y, Z, C four axes move simultaneously.

2. The four-axis three-linked engraving machine is mainly suitable for engraving planes and symmetrical, regular-shaped, symmetrical circular carving patterns that are not complicated, such as olive pits, cylindrical reliefs, that is, embossed carvings on the surface of the cylinder, wood Most of the stone materials, such as the famous Panlong Column, can be realized by this kind of three-axis and rotating-axis engraving machine. Four-axis suitable for carving can be used for regular, irregular, symmetrical and asymmetrical round carvings with complex and asymmetrical patterns. It is difficult to generate 4-axis curved surfaces, and there is generally no subsequent processing of 4-axis. Workpieces that can be processed by a 3-axis machine can also be processed by a 4-axis machine tool, but the workpiece that can be processed by a 4-axis machine tool may not be processed by a 3-axis machine tool.

3. When engraving on a quadruple and triple-link CNC engraving machine, whether it is flat or round, you can think of it as flat engraving. When carving, it is calculated according to the pulse. When the four-axis engraving machine is engraving, it is calculated according to 360, which means that each step is 0.000* degrees. Therefore, the operating principles of the three-axis engraving machine and the four-axis engraving machine are completely different. A four-axis engraving machine can only be called a true four-axis engraving machine if it is equipped with a special four-axis system and draw a special tool path, and it can also complete the work that only a four-axis engraving machine can complete.

4. The real four-axis linkage machine will be more expensive, and learning drawing will be more troublesome. The advantage is that the engraving speed is fast, and the four-axis can be easily done where the ordinary three-axis can’t engrave. Stair legs, general pillars, dragon holding pillars, European style furniture legs, four-axis three-linked engraving machine is to carve some reliefs and line carvings on the surface of the cylinder and can only carve simple figures like cylinders or ellipses. The four-axis linkage engraving machine is also called a three-dimensional engraving machine. This engraving machine can not only engrave cylindrical reliefs, but also engrave complex figures, European sofa legs, irregular curved surfaces, and semi-3D three-dimensional engraving.

5. Our suggestion for choosing a machine is that the different engraving requirements determine the different model and configuration of CNC milling machine 4 axis. Only the real four-axis engraving machine will be used for 3D three-dimensional engraving. For the engraving needs of cylindrical plane relief, you only need to use a three-axis system with a three-axis and rotary-axis engraving machine. After all, the price between the genuine four-axis system and the three-axis system is somewhat different. The fake 4-axis knife is always at the center of the A-axis, and the real 4-axis knife can go to both sides of the A-axis. It has a little effect on engraving the hollow objects inside. If the engraving surface is basically the same.

3 axis CNC machine has only three coordinate axes, X, Y, and Z, while the 4 axis kit has one more indexing head than the 3 axis kit. The indexing head is a common accessory used for machining complex products. The best auxiliary tool, controlled by the operating system, can realize linkage with other axes. It is mainly used for indexing and positioning machining of workpieces. The indexing device is generally located on the spindle of the machine tool. Under normal circumstances, the machine has three basic axes, X, Y, and Z. The other rotation and feed axes are the fourth axis. The latter can realize the positioning of the tool magazine, the rotary positioning of the rotary table and the indexing head, and more advanced The system can also perform interpolation operations with the basic axis to realize four and five axis linkage.

3 axis machine tool cannot process many surfaces even if it is horizontally rotated through the table. 4 axis is better than 3 axis in this respect. In terms of programming, the difference between 3 and 4 axis is basically the same. The operator who can operate the 3 axis machine tool can quickly get started with the operation of the 4 axis CNC machine, and the operation difference will not be much worse.