In the world of manufacturing and prototyping, precision and efficiency are crucial. The desktop CNC machine has revolutionized the way small-scale manufacturing and hobbyist projects are executed. These compact yet powerful machines offer the same capabilities as their larger counterparts but in a more accessible and affordable format.

Desktop CNC Milling Machine

Desktop CNC machines are compact, often portable, versions of industrial CNC machines designed for small-scale manufacturing, prototyping, and hobbyist use. They can cut, mill, and engrave a variety of materials, including wood, plastic, metal, and foam.

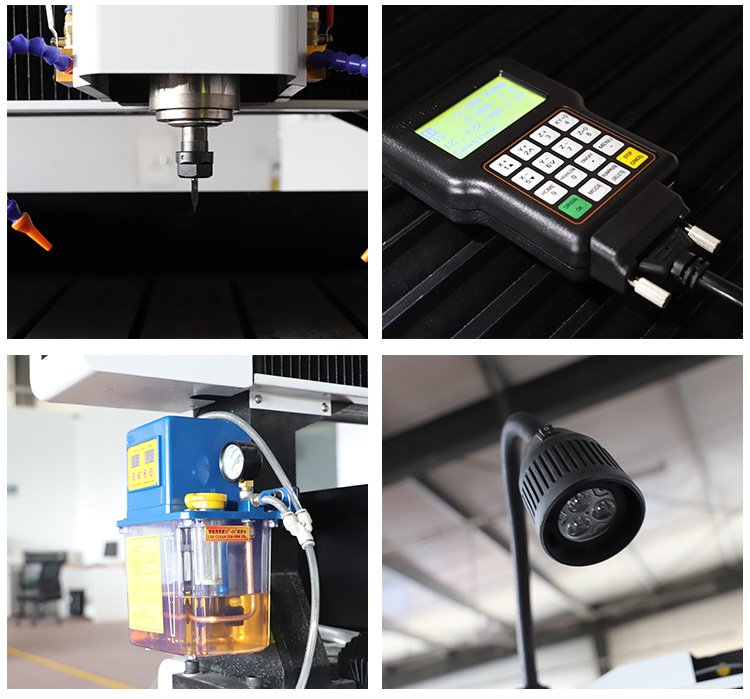

CNC desktop milling machine is a compact, computer-controlled tool designed to perform precise cutting, milling, engraving, and other operations on various materials. These machines are equipped with advanced features such as computerized controls, high-speed spindles, and automatic tool changers, allowing for intricate and accurate work.

Advanced Performance

- Use cast iron welding, good rigidity, good stability, not easy to deformation.

- Cover an area of an area small, the use of more convenient, is suitable for the machining of small size.

- Adopt cost-effective water cooling spindle, not only good cooling effect, and the machining accuracy is higher.

- Three axis adopt Taiwan TBI ball screw and linear guide, work stability, high precision, long service life.

- Control system simple operation, easy to learn and easy to use, to the greatest extent meet the needs of the user.

Features for Desktop Milling Machine

- Size and Portability: Desktop milling machines are smaller in size compared to their larger industrial counterparts. They are designed to be compact and portable, allowing for easy setup and movement within a workshop or small-scale manufacturing environment.

- Construction and Rigidity: Despite their smaller size, desktop milling machines are typically constructed with sturdy materials to ensure stability and rigidity during the machining process. A rigid frame helps maintain accuracy and precision during cutting operations.

- Work Area: The work area or table size of a desktop milling machine is smaller compared to larger milling machines. The size can vary, but it typically ranges from a few inches to a foot in width and length. The work area determines the maximum size of the workpieces that can be machined.

- Motor Power and Speed: Desktop milling machines feature motors that power the cutting tool. The motor power and speed determine the cutting capabilities of the machine. Higher motor power and variable speed options allow for cutting different materials and achieving desired cutting speeds.

- Cutting Tools: Desktop milling machines use a variety of cutting tools, including end mills, drill bits, and specialty milling tools. The choice of cutting tools depends on the material being machined and the desired cutting operation (e.g., drilling, milling, or routing).

- Control System: Most desktop milling machines feature computer numerical control (CNC) systems to automate and control the cutting process. CNC systems allow for precise control over tool movements and cutting paths, and they often come with software that enables design import, toolpath generation, and machining simulation.

- Software Compatibility: It is important to consider the software compatibility of the desktop milling machine. Some machines come with proprietary software, while others are compatible with popular CAD/CAM software that allows for design creation, toolpath generation, and G-code programming.

- Workholding and Tooling: Desktop milling machines may incorporate various workholding mechanisms such as vices, clamps, or T-slot tables to secure the workpiece during cutting. Additionally, tooling options, such as collets or quick-change tool holders, enable efficient tool changes during machining operations.

- Safety Features: Safety features such as emergency stop buttons, protective covers, and interlock systems are important for safe operation. Ensure that the machine you choose has adequate safety measures in place to protect the operator.

- Manufacturer Support and Service: Consider the reputation of the manufacturer and the level of support and service they offer. This includes technical assistance, warranty coverage, and availability of replacement parts.

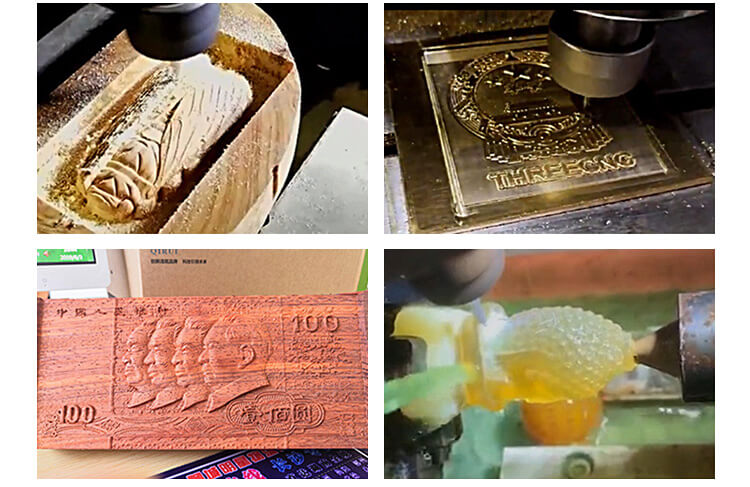

Types of Materials

Desktop CNC machines are versatile and can process a wide range of materials, including:

- Wood: Commonly used in woodworking and carpentry.

- Plastics: Utilized in prototyping and product design.

- Metals: Employed in jewelry making, metalworking, and small-scale manufacturing.

- Composites: Applied in automotive, aerospace, and consumer goods.

- Foam: Used in packaging, modeling, and crafts.

Applications of Desktop CNC Machines

Prototyping and Product Development

In the fields of prototyping and product development, desktop CNC machines are invaluable tools. Applications include:

- Rapid Prototyping: Creating functional prototypes quickly and accurately.

- Custom Parts: Producing custom components for various projects.

- Product Design: Testing and refining product designs before mass production.

Education and Training

Desktop CNC machines are widely used in educational institutions for teaching and training purposes. Applications include:

- Engineering Education: Providing hands-on experience with CNC technology.

- Vocational Training: Preparing students for careers in manufacturing and machining.

- STEM Programs: Enhancing science, technology, engineering, and mathematics education.

Hobbyists and Makers

For hobbyists and makers, desktop CNC machines offer endless possibilities for creative projects. Applications include:

- Woodworking: Crafting intricate designs and custom furniture.

- Model Making: Building detailed models and replicas.

- DIY Projects: Creating personalized items and gifts.

Small-Scale Manufacturing

In small-scale manufacturing, desktop CNC machines provide an affordable solution for producing high-quality parts. Applications include:

- Jewelry Making: Crafting intricate jewelry pieces with precision.

- Custom Signage: Producing custom signs and plaques.

- Art and Sculpture: Creating detailed art pieces and sculptures.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.