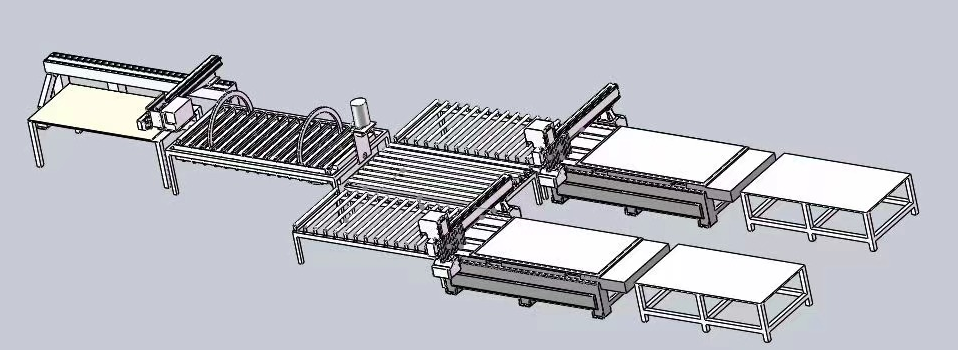

This autoloader series CNC router is a high-speed, automatic load/unload, heavy-duty CNC routing system for nested based feed through machining. This CNC machine is used majorly in the production of cabinets, door, closets, and custom furniture.

A CNC Cabinetry Router is used for engraving and cutting a wide range of materials like plywoods, MDF, chipboard, softwoods, hardwoods, melamine, and live edge wood. Besides this, it can also be used for acrylics, plastics, and solid surface materials.The X-Y Axis Travel of Cabinetry CNC Routers is available in 1300x2500mm/1500x3000mm/2000x3000mm. The Z-Axis Travel of the same is 300mm for all the models.

APPLICATION

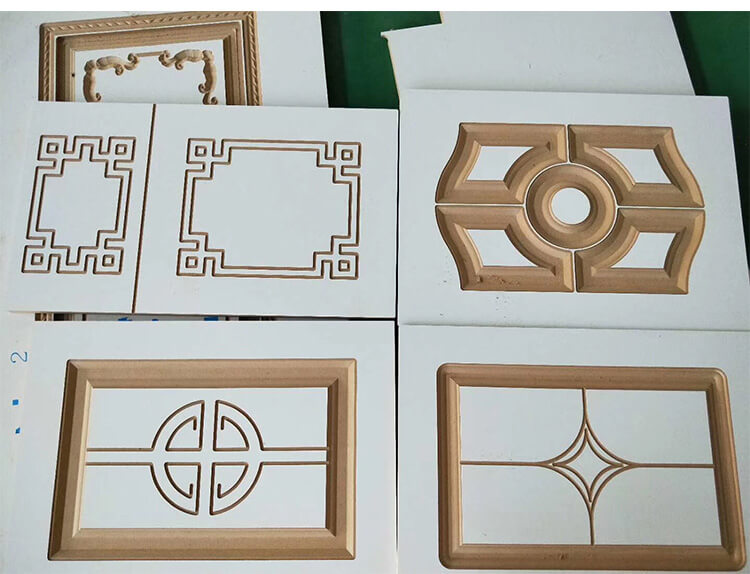

This full-automatic Intelligent CNC Router for Cabinet closet door furniture production has multi-functions of carving, engraving, milling, slotting, grooving, cutting, chamfer edge.

Full automatic Intelligent CNC Router Machine is mainly used in the furniture making industry, especially cabinet closet and door industries.

- The Frame or frameless cabinet construction

- Entertainment units

- Kitchen cabinets, islands and peninsulas

- Closets: Walk-ins, Reach-ins, Entries, Pantries

- Angled and radius cabinets and countertops

- Vanities

- Bookcases

- Home office workstations

- Fine custom cabinetry… and much more

Cabinetry CNC Router Machine

- CNC Router Basics: A CNC router is a computer-controlled cutting machine used for various tasks in woodworking, such as cutting, carving, engraving, and milling. It operates based on pre-programmed instructions, allowing for precise and repeatable cuts.

- Autoloader System: The autoloader component automates the material loading process. It can be designed to handle sheets of wood, particle board, MDF (Medium-Density Fiberboard), or other materials commonly used in cabinetry. This feature reduces manual labor, increases efficiency, and allows for continuous production runs.

- Cabinetry Applications: The CNC router is specifically tailored for cabinetry manufacturing, enabling the production of components like cabinet doors, panels, shelves, and intricate details with high precision.

- Tool Changing System: CNC routers typically have a tool-changing system that allows the machine to automatically switch between different cutting tools. This is crucial for handling various cutting and engraving tasks involved in cabinetry production.

- Dust Collection System: Woodworking generates a significant amount of dust. An effective dust collection system is essential to maintain a clean working environment, ensure the longevity of the machine, and protect operators from exposure to dust.

- Computer Control and Software: The CNC router is controlled by a computer, and specialized software is used to create the design files and generate toolpaths. The operator can program the machine to produce specific cabinetry designs.

- Precision and Accuracy: CNC routers are known for their high precision and accuracy, ensuring that each piece is manufactured to the exact specifications of the design. User Interface: The machine typically has a user-friendly interface for the operator to input parameters, monitor the machining process, and troubleshoot if necessary.

- Safety Features: Safety features such as emergency stop buttons, protective enclosures, and sensors are essential to ensure a safe working environment.

- Customization: The machine can be customized to accommodate different sizes and types of materials. This flexibility is important for manufacturers who work with a variety of cabinetry designs. Production Speed: Autoloader systems contribute to increased production speed, as the machine can continue operating with minimal downtime for material loading.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.