CNC Wood Router for Cabinet Making

A CNC wood router is a computer-controlled cutting machine that allows woodworkers to create intricate designs, precise cuts, and detailed carvings with minimal manual intervention. For cabinet makers, this technology has revolutionized the way cabinets are designed, cut, and assembled, significantly improving efficiency, reducing waste, and enhancing the quality of the final product.

A collection of efficient and flexible CNC tools for building cabinets has been built by our company using sophisticated equipment. These devices are capable of undertaking various works from accurate cutting and drilling to intricate shaping and profiling. They have been constructed using quality elements that guarantee their strength as well as longevity; moreover, these items come with complete warranties supported by good customer care services.

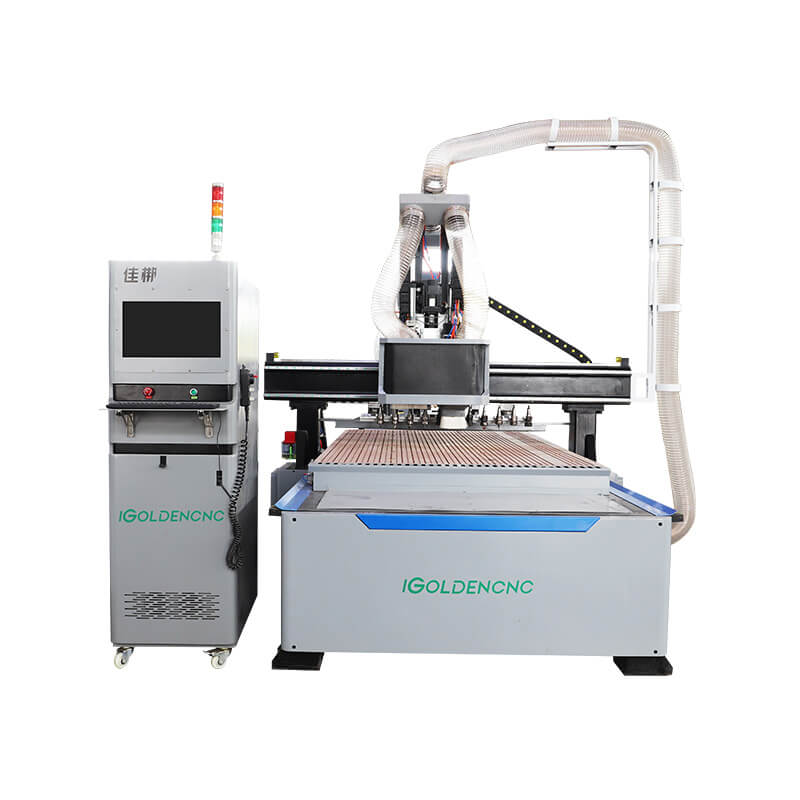

Cabinets Making CNC Router

CNC Router Table for Cabinet Making Parameter

| Technical indicators | parameter |

| Model | iGC-TD-1325 |

| Working area(X,Y,Z) | 1300*2500*250mm |

| Max. empty speed | 60000mm/min |

| Max. working speed | 30000mm/min |

| Spindle Power | HQD 9.0kw air cooled tool change spindle |

| Drill bag | 9 hole vertical row drilling |

| Spindle speed | 18000rpm |

| positional accuracy | 0.03mm |

| X,Y axis drive | Rack |

| Z axis drive | Ball screw |

| Repeated positioning accuracy | 0.02mm |

| Command language | G Code |

| Port | USB |

| Working voltage | AC220V/380V, 50Hz |

We offer customized services according to your requests such as the working area and specifications.

5+4 vertical drilling device

Using HQD 9.0kw air cooled automatic tool change spindle +9 hole row drilling package, reliable quality, low noise, long life.

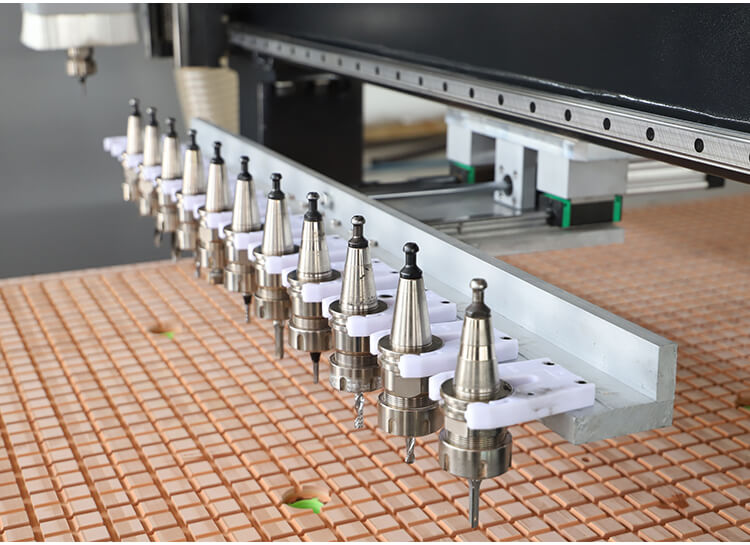

Automatic Tool Change

Manufactured with linear tool magazine with 12 tools, it can realize automatic tool change according to customer needs.

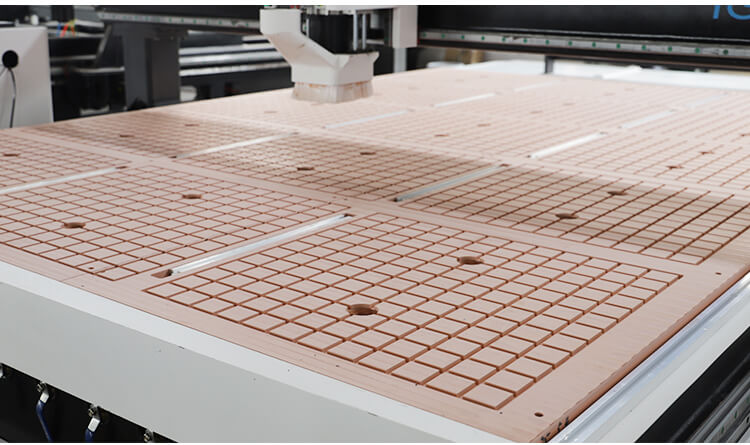

Vacuum adsorption table

Vacuum adsorption table, strong adsorption force, each area can be controlled separately.

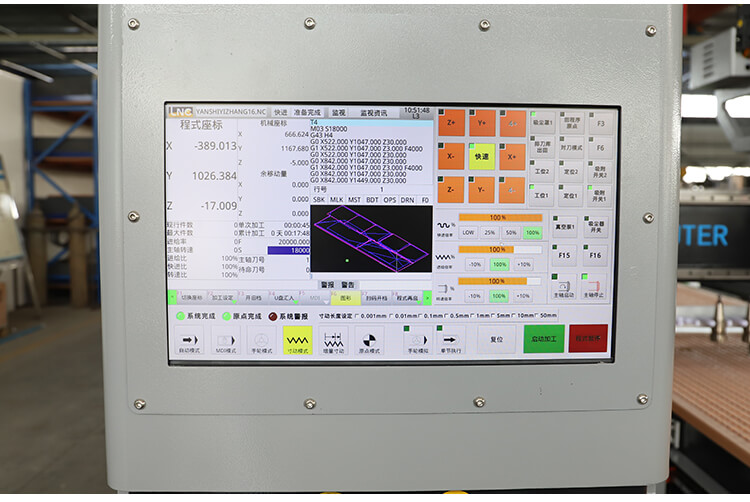

Taiwan LNC System

Control system is simple, convenient and easy to learn, users can quickly get the fleciblity to master the use of equipment, strong independence.

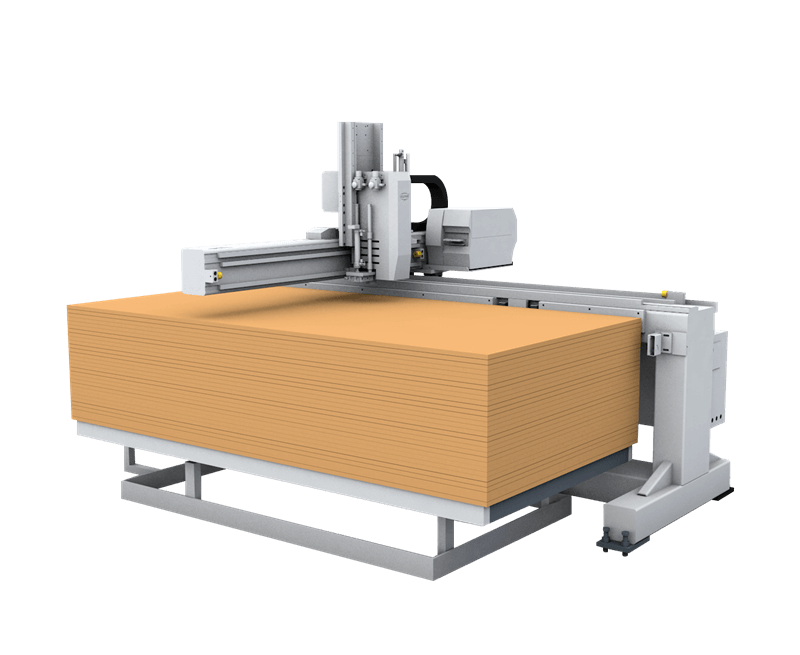

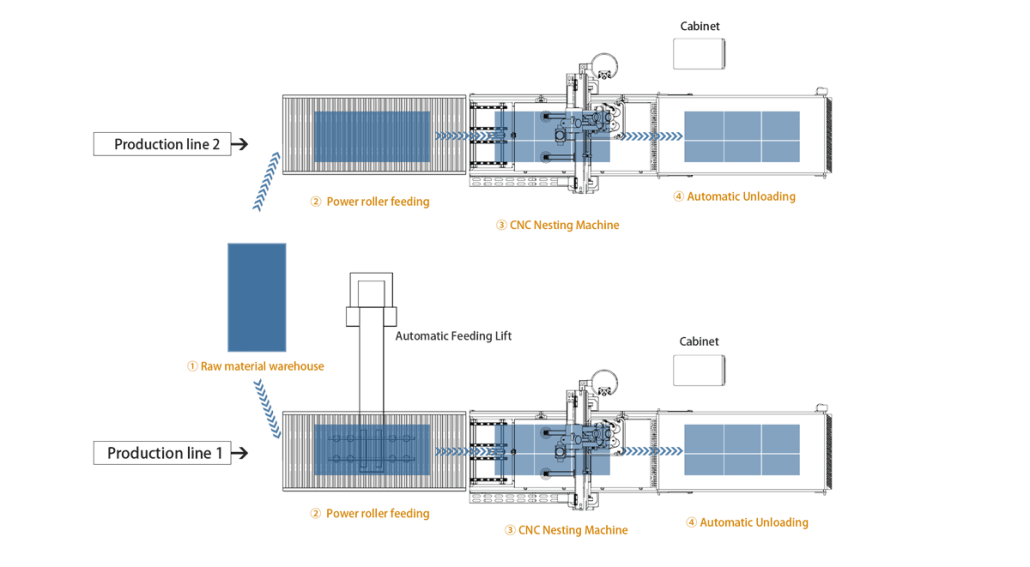

(Option) Automatic loading unloading system

Highly automated discharge solution with automatic loading and unloading system. The entire work cycle of loading, nesting, drilling, and unloading is performed automatically, thereby achieving the highest productivity and zero downtime,it can effectively improve the production efficiency of cabinets and panel furniture.

Applications of CNC Wood Routers in Cabinet Making

1. Precision and Accuracy One of the most significant advantages of using a CNC wood router for cabinet making is its ability to produce highly precise and accurate cuts.

2. Efficiency and Speed Compared to traditional woodworking methods, CNC wood routers are much faster and more efficient. The machine can cut multiple parts simultaneously, reducing the time it takes to complete a project.

3. Versatility CNC wood routers are incredibly versatile and can be used to cut a wide range of materials, including:Solid wood Plywood MDF (Medium-Density Fiberboard) Particleboard Laminates

4. Reduced Waste The precision of CNC wood routers helps to minimize waste by ensuring that each cut is accurate and clean.

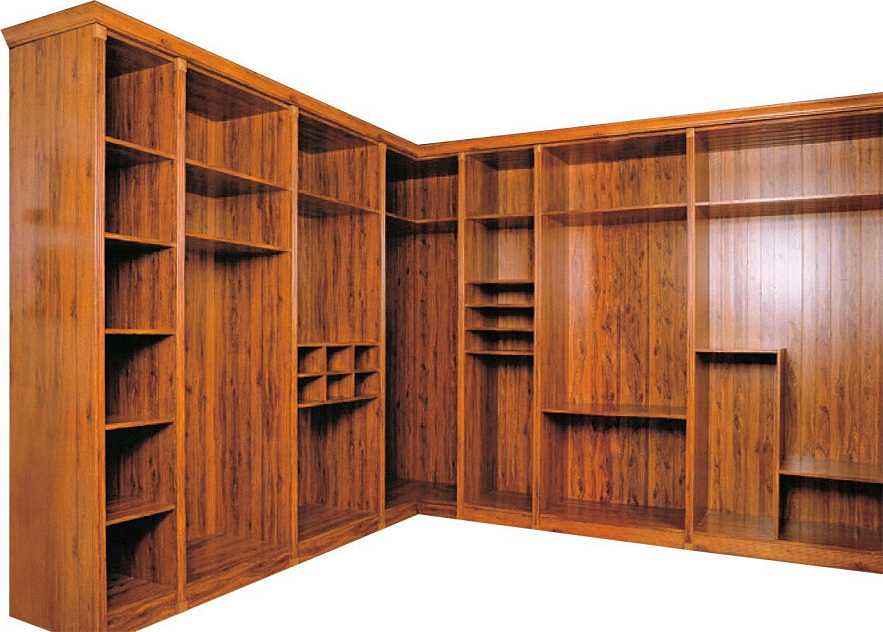

5. Customization For custom cabinet makers, CNC wood routers offer the ability to create unique, one-of-a-kind designs. The CNC system can be programmed to cut intricate patterns, engravings, and decorative details that would be difficult or impossible to achieve with traditional woodworking tools.

CNC Cabinet Machine Application

Woodworking Industry:

Cabinet making CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

Decoration Industry:

Art model, wall art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other industrial wood works.

CNC Router for Cabinet Making FAQ

The CNC wood router operates by following a set of instructions called G-code, which is generated from a CAD (Computer-Aided Design) file. The CAD file contains the design or pattern that the operator wants to cut, and the CNC software translates this design into G-code. The G-code tells the machine how to move the cutting tool along the X, Y, and Z axes to create the desired shape.

The operator loads the wood onto the machine’s worktable, secures it in place, and starts the cutting process. The CNC wood router then moves the cutting tool according to the programmed design, making precise cuts, carvings, or engravings in the wood.

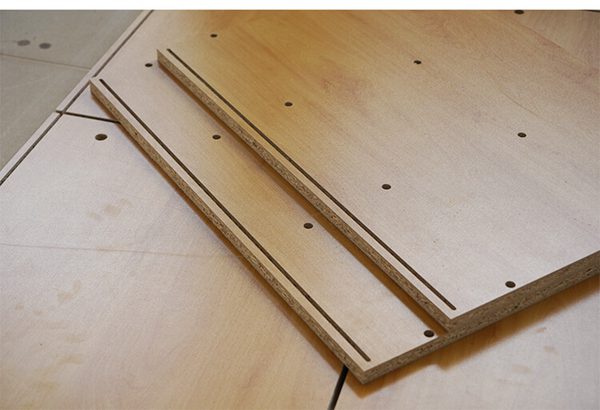

1. Cutting Cabinet Components

One of the primary uses of CNC wood routers in cabinet making is cutting the various components that make up a cabinet, such as:

- Cabinet doors

- Drawer fronts

- Side panels

- Shelves

- Back panels

The CNC wood router can be programmed to cut these components with precise dimensions, ensuring that they fit together perfectly during assembly.

2. Creating Decorative Details

CNC wood routers are also used to create decorative details on cabinet doors and drawer fronts. The machine can be programmed to carve intricate patterns, engravings, and edge profiles, allowing cabinet makers to offer custom designs that add a unique touch to their cabinets.

3. Dovetail and Box Joints

For cabinet makers who want to create strong, durable joints, CNC wood routers can be used to cut dovetail and box joints with precision. These joints are commonly used in drawer construction and are known for their strength and durability.

4. Drilling Holes for Hardware

In addition to cutting cabinet components, CNC wood routers can also be used to drill holes for hardware, such as hinges, drawer slides, and handles. The machine can be programmed to drill holes at precise locations, ensuring that the hardware is installed correctly and functions smoothly.

5. Cutting Cabinet Frames

CNC wood routers can also be used to cut the frames that hold the cabinet components together. The machine can cut the frame pieces with precise dimensions, ensuring that they fit together perfectly and provide a sturdy foundation for the cabinet.

1. Size and Cutting Area

One of the first factors to consider when choosing a CNC wood router for cabinet making is the size of the machine and its cutting area. The cutting area should be large enough to accommodate the size of the wood panels you’ll be working with. For cabinet making, a machine with a cutting area of at least 4×8 feet is recommended, as this is the standard size for most plywood and MDF sheets.

2. Spindle Power

The power of the router spindle is another important consideration. A more powerful spindle will allow you to cut through thicker and denser materials with ease. For cabinet making, a spindle with at least 3 to 5 horsepower is recommended, as this will provide enough power to handle most types of wood and composite materials.

3. CNC Software Compatibility

Ensure that the CNC wood router you choose is compatible with the CNC software you plan to use. Most machines come with their own proprietary software, but it’s essential to verify that it integrates well with your existing design and production systems. Look for software that is user-friendly and offers features like 3D modeling, tool path optimization, and nesting.

4. Dust Collection System

A dust collection system is an essential feature for any CNC wood router, especially when working with wood. Sawdust can accumulate quickly during the cutting process, and a good dust collection system will help keep the workspace clean and improve the machine’s performance.

5. Budget

CNC wood routers vary in price depending on their capabilities and features. Determine your budget and weigh the long-term return on investment when choosing a machine. While more advanced machines may have a higher upfront cost, they offer greater efficiency, precision, and versatility, which can save money in the long run.