CNC wood engraving machines are advanced tools designed for efficiently and precisely carving designs, patterns, and text into wooden surfaces. These machines utilize Computer Numerical Control (CNC) technology, which allows for automated and highly accurate engraving processes, making them ideal for both industrial applications and small-scale woodworking projects.

CNC Wood Engraving Machine

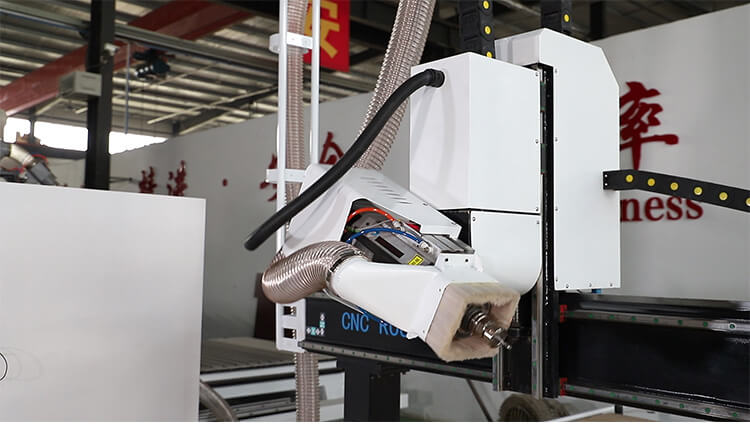

This machine is a ATC CNC router machines,And this automatic wood engraving machine is all steel construction, which can provide the rigid foundation required for ultra-smooth routing results. The ATC CNC Router machine comes standard with the 9KW(12HP) automatic tool changer with 8-position tool rack,So this machine has fast processing speed and high processing quality. This woodworking engraving machine can process wood,Mdf,plywood,acrylic,soft metal and so on.

This woodworking engraving machine has Hybrid Vacuum and T-slot table, so we can quickly fix the workpiece. This ATC CNC router machines are powered by hybrid servo drive motors and controlled by an easy-to-use and learn handheld controller (DSP-Controller).

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.