In today’s competitive manufacturing landscape, efficiency and precision are non-negotiable. Meet the CNC Panel Cutting Machine – your ultimate solution for flawless material processing, designed to transform how you handle wood, plastics, composites, and non-ferrous metals. Whether you’re crafting furniture, cabinetry, signage, or architectural components, this advanced machinery empowers your workflow with unmatched accuracy and speed.

CNC Panel Cutting Machine

Introduction

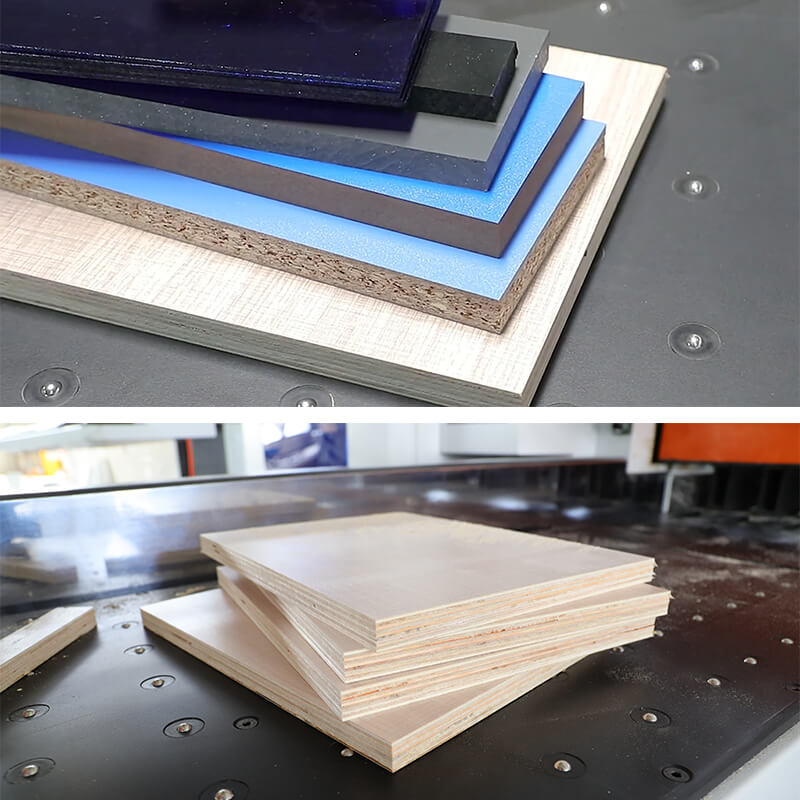

A CNC panel cutting machine is an essential tool in woodworking, metal fabrication, and industrial manufacturing. It provides precision, efficiency, and automation in cutting various materials, including wood, MDF, plywood, acrylic, aluminum, and composite panels.

In this comprehensive guide, we will explore the features, benefits, types, and applications of CNC panel cutting machines. Whether you’re a professional manufacturer or a DIY enthusiast, this article will help you understand how to choose and use the right CNC panel cutter for your needs.

CNC Panel Saw

- Uses a circular saw blade to cut large panels.

- Ideal for wood, MDF, plywood, and particleboard.

- Common in furniture manufacturing and cabinetry.

Why Choose Our CNC Panel Cutting Machine?

Pixel-Perfect Precision: Equipped with high-resolution servo motors and cutting-edge software, our machine delivers tolerances as tight as ±0.1mm, ensuring every cut meets the strictest quality standards.

Lightning-Fast Efficiency: Optimize production timelines with rapid cutting speeds of up to 120m/min and automatic tool-changing systems that minimize downtime.

Versatility Redefined: Seamlessly switch between materials – from delicate veneers to robust MDF, PVC, and aluminum composites – using customizable blade configurations and pressure settings.

Smart Automation: Integrated CAD/CAM compatibility allows direct file import (DXF, DWG, etc.), while user-friendly interfaces enable even novice operators to master complex designs in minutes.

Cost-Saving Design: Reduce material waste by up to 30% with AI-powered nesting software that maximizes panel utilization, translating to higher profits and sustainability.

Applications That Inspire Innovation

- Furniture Manufacturing: Craft intricate joints, curves, and cutouts for bespoke designs.

- Cabinetry & Joinery: Achieve flawless edges and perfect fits for modular systems.

- Architectural Models: Execute detailed 3D components with micron-level consistency.

- Signage & Displays: Produce eye-catching letters and shapes in acrylic, foam, or aluminum.

- Automotive & Aerospace: Fabricate lightweight interior panels with aerospace-grade precision.

Built to Last, Designed to Impress

Our CNC Panel Cutting Machine isn’t just powerful – it’s engineered for longevity. Featuring a rigid steel frame, dust-proof linear guides, and proactive maintenance alerts, it thrives in demanding industrial environments. The 24/7 technical support and remote diagnostics ensure you’re never left stranded.

Conclusion

A CNC panel cutting machine is a game-changer for industries requiring precision, efficiency, and automation. Whether you’re in woodworking, metal fabrication, or industrial manufacturing, investing in the right CNC cutter can enhance productivity and improve cutting quality.

By understanding the different types, features, and applications, you can choose the best CNC panel cutting machine for your needs.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.