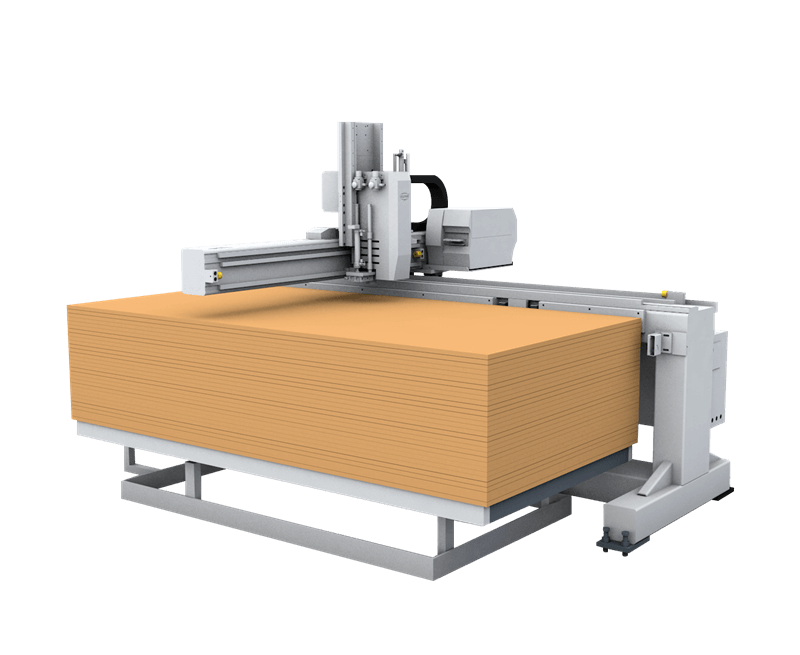

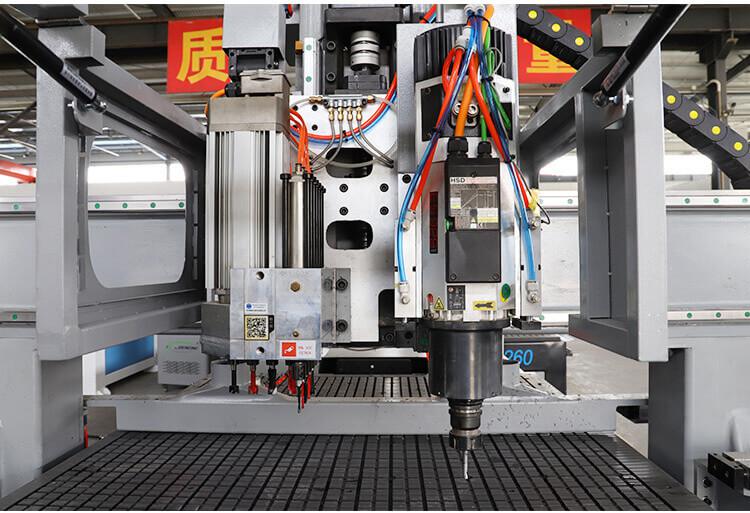

ATC CNC Nesting Machine with Disc Tool Changer

iGC-DT-1325

ATC CNC nesting machine is a versatile and high-precision tool that can significantly improve the efficiency and accuracy of various manufacturing processes, making it a valuable asset for a range of industries.The nesting CNC machine is a computer numerical control equipment specially designed for the production of panel furniture line.

It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.

This ATC nesting CNC machine with disc tool changer is equipped with a 9.0kw air-cooled spindle, and independent operation. Usually used in conjunction with labelling coding machines and automatic loading and unloading platforms. High speed, high precision, high efficiency and stability. It is suitable for processing various cabinet doors and wooden doors.

ATC CNC Router Video

CNC Nesting Machine Parameter

| X, Y Axis Working Area | 1300*2500mm |

| Z Axis Working Height | 250mm |

| Positioning Accuracy | 0.03mm |

| Re-positioning Accuracy | 0.02mm |

| X, Y Axis Structure | Linear Guide Rail, Gear Rack |

| Z Axis Structure | Linear Guide Rail, Screw |

| Max. Running Speed | 60000mm/min |

| Max. Working Speed | 30000mm/min |

| Spindle | 9.0kw ATC Air-cooling Spindle |

| Spindle RPM | 24000rpm/min |

| Working Voltage | AC 380V±10%/50-60Hz |

| Machine Weight | 2300kg |

We offer customized services according to your requests such as the working area and specifications.

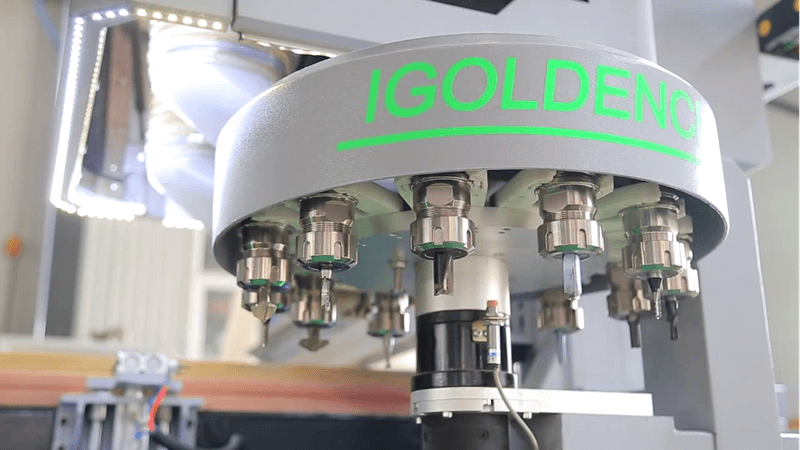

With 10 high-speed disc tool magazines, tool change can be completed within 8 seconds, which effectively improves production efficiency.

Spindle

With Italian HSD 9 vertical drills, multiple vertical holes can be processed at one time, effectively improving the drilling efficiency.

9.0kw ATC air-cooling and 5+4 row drill package

Independent large computer cabinet

Taiwan LNC system + wireless handwheel

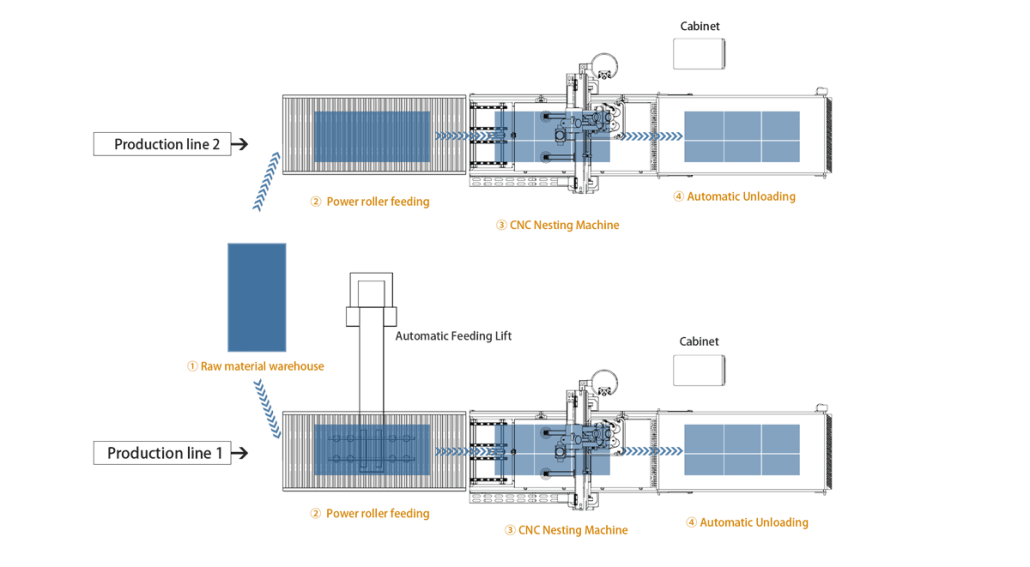

(Option) Automatic loading unloading system

Highly automated discharge solution with automatic loading and unloading system. The entire work cycle of loading, nesting, drilling, and unloading is performed automatically, thereby achieving the highest productivity and zero downtime,it can effectively improve the production efficiency of cabinets and panel furniture.

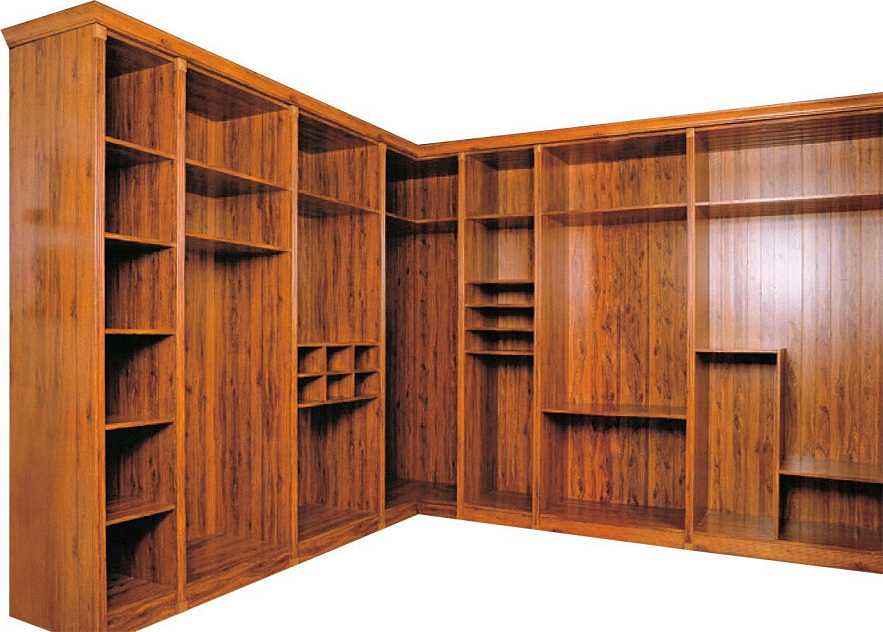

CNC Nesting Machine Application

>Production and processing of various types of furniture: cabinets, wardrobes, office furniture, computer tables, children’s furniture, panel furniture, cutting and cutting, slotting and perforating, decoration hollow frames, soft bag background wall production, etc.;

>Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc .;

>Wood products processing: clocks, electrical countertops, sporting goods and equipment;

>Musical instrument industry: three-dimensional curved surface and shape cutting of sculptable musical instruments;

>Crafts industry: photo frames, jewellery boxes.

Contact Us Today to Get Price!

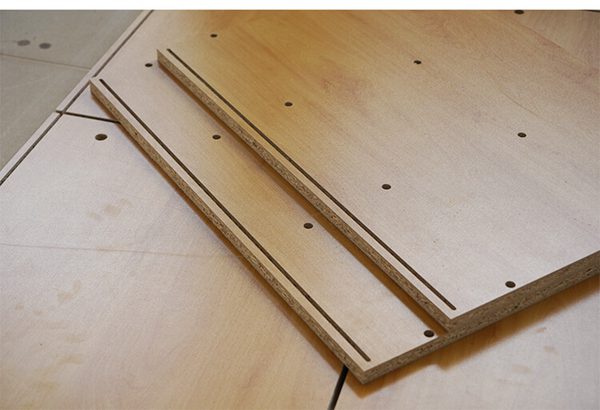

Nesting CNC machine is a smart machine tool in customized panel furniture production including cabinet door making, closet door making, home door making, wardrobe making, home decoration making, cabinets making, home furniture making, shop and office furniture making. In the production process, the operator just as porters, the Intelligent CNC nesting machines can realize automatic paste barcode, automatic feeding, drilling, slotting, cutting, automatic uploading, automatic retrieval processes for cutting side hole, slot on the back, back hole, the whole process don’t need human judgment, automatic processing, get rid of the dependence of woodworking professional and technical workers.

Besides, automatic feeding CNC nesting machine instead of the traditional push table saw or precision saw, to prevent the occurrence of work-related injuries, the health of employees is guaranteed.

A nesting machine is a specialized computer-controlled machine used to optimize the placement and cutting of various parts or components from sheet materials, such as wood, metal, plastic, or composite materials. Its primary purpose is to minimize waste and improve material utilization, making it an essential tool in industries where efficient material usage is critical.

Here’s what a nesting machine does:

- Nesting Optimization: The nesting machine’s software takes a list of parts or components to be cut and the size and shape of the sheet material to be used. It then automatically arranges and optimizes the placement of these parts on the sheet, aiming to minimize material waste while ensuring efficient cutting and machining.

- Material Utilization: By tightly packing parts on a sheet, a nesting machine maximizes the use of the available material. This results in reduced material waste and cost savings, as fewer sheets are required to produce the same number of parts.

- Precision Cutting: Once the nesting layout is optimized, the machine uses various cutting tools (e.g., routers, saws, lasers) to cut or machine the parts from the sheet material. It ensures precise and accurate cutting, maintaining tight tolerances.

- Continuous Operation: Nesting machines are designed for continuous operation, as they can efficiently cut multiple parts from a single sheet without the need for manual intervention between cuts.

- Speed and Efficiency: The automated nature of nesting machines increases production efficiency, reduces labor costs, and speeds up the manufacturing process.

- Material Variety: Nesting machines can work with a wide range of materials, including wood, metal, plastic, foam, and composites. This versatility makes them suitable for various industries.

Applications of nesting machines include:

Woodworking: In the production of furniture, cabinetry, and other wooden products.

Metal Fabrication: Cutting and shaping metal parts for various applications.

Signage and Graphics: For precise cutting of materials for signs, displays, and graphics.

Aerospace and Automotive: Manufacturing components with precision and efficiency.

Textiles: Optimizing the cutting of fabric and textile materials in the garment industry.

As a concept, nesting can be thought of similarly to packing a box for a move or packing a suitcase for a trip. The goal when packing is to arrange all the items you need within their container such that everything fits compactly and minimal space is wasted.

Nesting in CNC work is much the same, aiming to arrange as many of the parts to be cut as possible within as few sheets of material as possible thus increasing your profitability.

Whether you are a small business or a hobbyist, you would want to save material waste and money.

When manufacturing multiple parts, you would need to find the most optimum cutting pattern on your workpiece.

You can manually do the nesting, i.e., arrange the designs yourself and find the best fit.

But this often requires you to put in a lot of effort yourself, especially if you are on a budget and the volume of production is high.

Using CNC nesting software will help you arrange the design in the most efficient manner and save a lot of time, thereby increasing productivity.

When working with non-recyclable materials, reducing the material waste becomes even more critical as the leftover pieces are rendered useless, which can account for a huge loss and also be harmful to the environment.

Hence, CNC nesting helps to reduce the need for logging, mining, and manufacturing of such materials.

CNC nesting software also implements advanced algorithms that are able to find the most space-efficient layout by considering some factors that you might miss out on if you do it manually.

Using nesting software increases productivity and efficiency as the cutting toolpath can be set up in such a way that adjacent parts can share a cut.

This reduces the travel distance of the tool and saves time and power.