5 Axis Gantry Moving CNC Machining Centre

5 axis CNC machine is also known as 5 axis CNC router, 5 axis CNC machining center, 5 axis CNC milling machine, or multi axis CNC machine.Adcanced 5 axis cnc router machine, also known as 5 axis cnc machining center, 5 axis cnc milling machine, is good at space curved surface processing, special-shaped processing, hollow processing, punching, oblique drilling, chamfering, etc. It is widely used in aerospace, military scientific research, precision machinery, high-precision medical equipment, normal manufacturing, etc.

CNC 5 Axis Gantry Machining Center Video

5 Axis CNC Router Machine Parameter

| X, Y Axis Working Area | 1720*3040mm |

| Z Axis Working Height | 600-1200optionedmm |

| Positioning Accuracy | 0.03mm |

| Re-positioning Accuracy | 0.02mm |

| Body Structure | Welding Body |

| X, Y Axis Structure | Linear Guide RailGear Rack |

| Z Axis Structure | Linear Guide RailScrew |

| Max. Running Speed | 60000mm/min |

| Max. Working Speed | 30000mm/min |

| Spindle | 14kw ATC Spindle(Optioned) |

| Spindle RPM | 24000rpm/min |

| Working Voltage | 220V/ 380V±10%50-60Hz |

| Machine Weight | 2300kg |

We offer customized services according to your requests such as the working area and specifications.

Thickening Steel Gantry

The damage to the motion conduction device is small, and the resistance to the drive motor is small, so that the accuracy of the gantry is maintained for a long time, the service life is improved, and the maintenance and use costs are reduced.

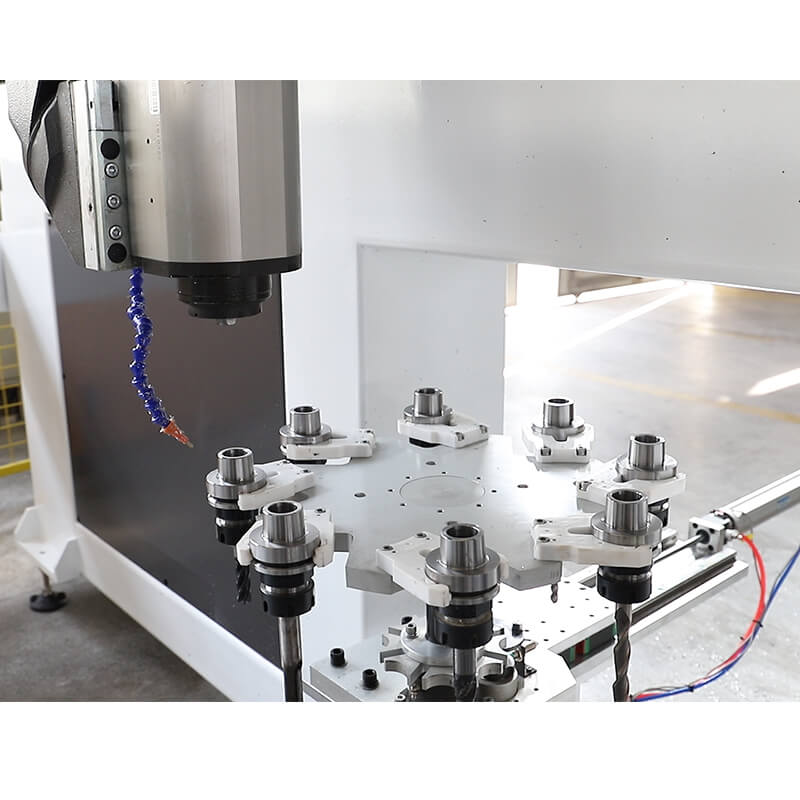

Disc Tool Bank

Tool magazine with 6-10 discs on the side.Load 6-10 tools with different functions at one time and change the tool in 2 seconds.Save time for manual tool change and improve work efficiency.

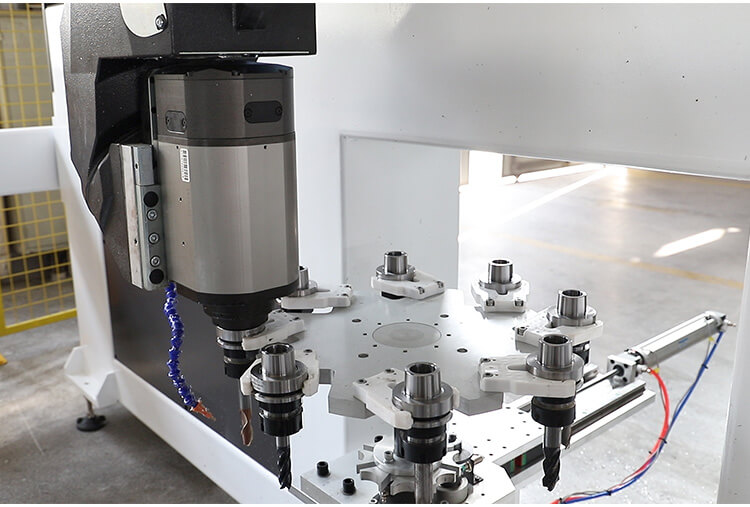

14KW SCM five-axis spindle + swing head

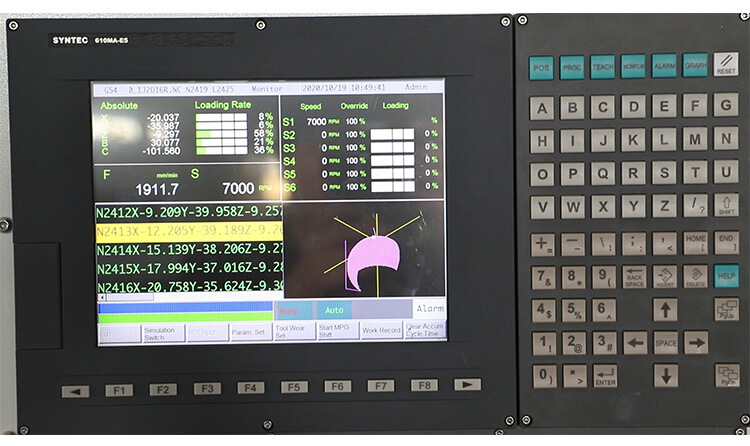

Taiwan SYNTEC System

The System with break point memory, power outages continued carving, processing time forecast, and other functions to ensure that accidental processing.

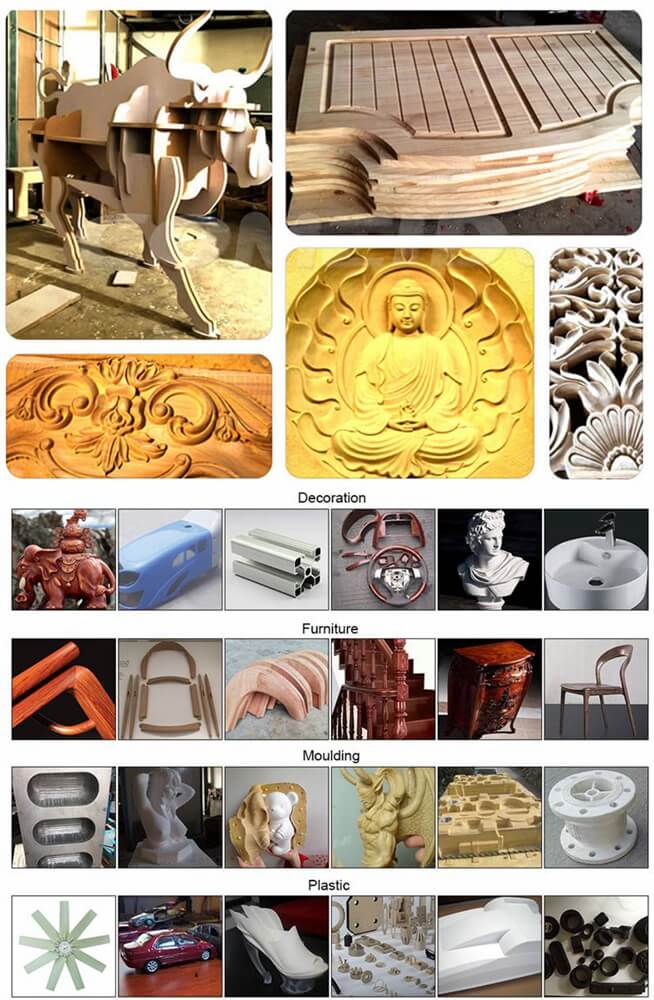

Application of 5 Axis CNC Router Machine

Composite materials industry: Trimming and punching of various composite materials such as plastic parts, glass fiber reinforced plastic parts, rubber and plastic products;

Mold industry: 5 axis processing of FRP wood mold, casting wood mold, resin products, sludge model and various non-metal molds;

Ceramic sanitary industry: 5 axis processing of gypsum molds, 5 axis processing of various gypsum products;

Furniture industry: 5 axis processing of solid wood furniture, 5 axis processing of various furniture tenon and mortise pieces, 5 axis processing of stair elbows, and 5 axis processing of various furniture.

Reviews

The five-axis machining center can process planes, curved and inclined surfaces, oblique holes, 2D and 3D curved surfaces, and 3D lines. Besides, a 5 axis CNC machine can realize continuous milling, engraving, drilling, and sawing in all directions with one fixing and positioning of the workpiece.

The high-precision 5 axis machining centers have extensive applications in the furniture, molding, construction, machine manufacturing, civil and military industries. It can be used to produce:

- Box-type parts, like automobile engine cylinder heads, clutch and gearbox housing, pumps

- Complex curved surfaces, like bevel gear wheels, pinions, impellers Irregular parts, including drilling, milling, boring, expanding, reaming, and rigid tapping processes

- Molds, such as ship molds, automotive molds, construction molds

- Statues and sculptures Large-sized wood furniture

- Styrofoam or gypsum models

There are many types of horizontal 5 axis CNC machine.

1. Double swing head form: two coordinate axes directly control the direction of the tool axis.

2. Drooping rotary head form: two coordinate axes are at the top of the tool, but the rotary axis is not perpendicular to the linear axis.

3. Double turntable form: two coordinate axes directly control the space rotation.

4. The sagging table form: two coordinate axes are on the table, but the rotation axis is not perpendicular to the axis.

5. One swing and one turn form: one coordinate axe acts on the tool and the other acts on the workpiece.

5 axis CNC machine features with high efficiency and high precision, and complex machining can be completed in one clamping of the workpiece. It can be adapted to the processing of modern molds such as auto parts and aircraft structural parts. There is a big difference between a five-axis machining center and a five-sided machining center. Many people don’t know this and mistake the pentahedral machining center as a five-axis machining center. The five-axis machining center has five axes X, Y, Z, A, C. X, Y, Z axis and A, C axis form a five-axis linkage processing, good at space surface processing, special-shaped processing, hollow processing, punching, oblique Holes, bevel cuts, etc. The “pentahedral machining center” is similar to a three-axis machining center, except that it can do five faces at the same time, but it cannot do special-shaped machining, beveled holes, cut bevels, etc.

Speaking of the features of the five-axis CNC machine tool, it is necessary to compare with the traditional three-axis CNC machines. 3 axis CNC machine is relatively common in manufacturing, and there are several forms such as vertical, horizontal and gantry. Common machining methods include end milling and side cutting of end mills. The profiling of ball-end knives and so on. However, no matter which form and method have a common feature, the direction of the tool axis remains unchanged during the machining process, and the machine tool can only realize the rectangular coordinates of the tool through the interpolation of the three linear axes of X, Y, and Z Movement in the department. Therefore, in the face of the following products, the disadvantages of the low efficiency of the three-axis machine tool, the poor quality of the processed surface, and even the inability to process are exposed.

The 5 axis CNC machine price should be the most concerned factor for everyone who wants to buy 5 axis CNC router. Because 5 axis CNC router machine has been more and more widely used in various fields, more and more factories have chosen to use 5 axis CNC mill machines to produce workpieces, so the 5 axis CNC machine price will be a bit high Because its main customers are factories, not individuals. If you have a factory that needs a 5 axis CNC machine to process workpieces, then I think this would be a good choice. The reason for the high price of the 5 axis CNC machine is also related to the configuration of the machine and the quality of the machine. The higher the manufacturing cost of the machine itself and the better the quality of the machine, the more expensive it will be. Of course, in addition to this industrial 5 axis CNC routers, IGOLDENCNC also has a variety of small 5 axis CNC machines and mini 5 axes CNC routers. These machines are also five-axis, but the structure is simple and the functions are relatively small, but these small 5 The price of axis CNC machine is relatively cheap about 3000 US dollars. The price of an industrial-grade 5 axis CNC machine is about US$20,000 to US$50,000, so the price range of the 5 axis CNC machine price is also very large. If you want to buy a 5 axis CNC machine, you can tell BuyCNC For your budget and what you want to process, we will have professional engineers recommend the most suitable 5 axis CNC router machine for sale.