In today’s digital age, technology has revolutionized the way businesses operate. One such technological advancement that has greatly impacted the woodworking industry is the CNC machine. These machines have made woodworking more efficient, precise, and cost-effective, making them an ideal investment for small businesses in the woodworking industry.

Wood CNC Machine

A Wood CNC Machine is a powerful tool used for automating the process of cutting, carving, drilling, and engraving wood materials. These machines are highly versatile and can perform a variety of tasks with precision and efficiency, making them popular in woodworking, furniture making, and custom wood design industries.

IGIOLDEN IGW-ATC

The Inventables G8 is a popular choice among small business owners due to its versatility and affordability. This CNC machine offers a large cutting area, allowing you to work on various sizes of wood pieces. It comes with an easy-to-use software interface, making it suitable for beginners and experienced woodworkers alike. The G8 also has a strong and sturdy frame, ensuring stability and precision during the cutting process.

Automatic Tool changer (ATC) CNC machining center is suitable for all kinds of complex products or various machining. It can realize the cutting, engraving, drilling, wiring and grooving of wood, medium density board, acrylic, PVC, plastic, foam, stone, soft metal and other materials.

It can be equipped with different tool library and quantity according to different production process, and other options can also be added, such as spindle swing, side rotating shaft, etc.

IGIOLDEN iGC

The iGC is a professional-grade CNC machine suitable for small businesses that require high precision and performance. It offers a large cutting area and a powerful spindle, allowing you to work on complex wood projects with ease. The iGC is known for its exceptional build quality and durability, ensuring long-term reliability. It also comes with advanced software features, providing extensive control and customization options.

The CNC cutting machine uses professional cutting software to play its powerful functional advantages, which can be designed online, single click, optimize the plate, positioning, etc., improve the utilization rate of the plate, can realize automatic loading and unloading, save labor, and greatly improve the processing speed and efficiency.

It can be used with edge banding machine, laminating machine, side hole machine and other machines to customize the whole house.

Suitable for all kinds of furniture production and processing: cabinets, wardrobes, office furniture, computer desk, children’s furniture, panel furniture, cutting, grooving and perforating, decorative hollow frame, soft bag background wall production, etc.

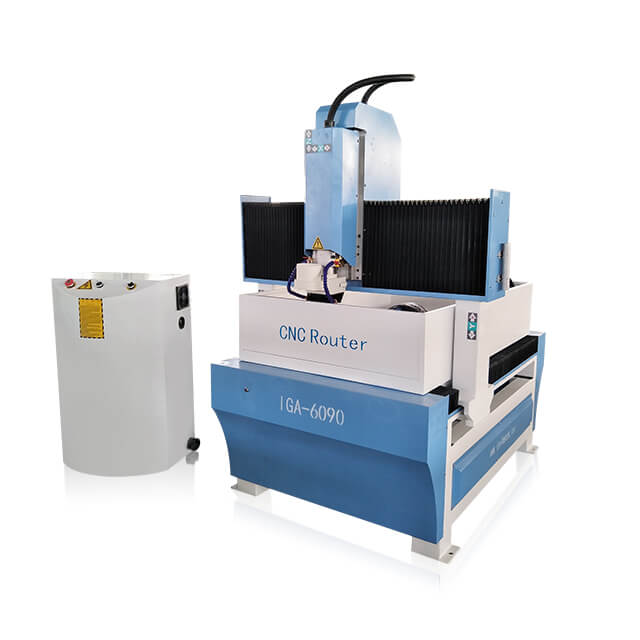

IGW-6090

The ShopBot Desktop is a compact and versatile CNC machine that is perfect for small woodworking businesses with limited space. Despite its small size, it offers a generous cutting area and a robust construction. The Desktop is known for its user-friendly interface and intuitive software, making it suitable for beginners. It also comes with a range of optional accessories, allowing you to expand its capabilities as your business grows.

Semi-enclosed engraving machine on the basis of the standard mold machine increases the semi-enclosed protective cover, more safe and efficient, can be customized size 4040/6060/6090/8080, equipment covers a small area, high precision, fast speed, low cost, no pollution;

Mainly used for a variety of small mold engraving, widely used in glasses, watches, panels and other large mold three and outer surface processing, such as badges, brands, graphics, text and so on. It is often used in woodworking, advertising, decoration, automobile, injection mold, hardware mold, engraving mold and other industries.

Products can be customized, IGOLDENCNC will provide you with the right solution according to your production needs.

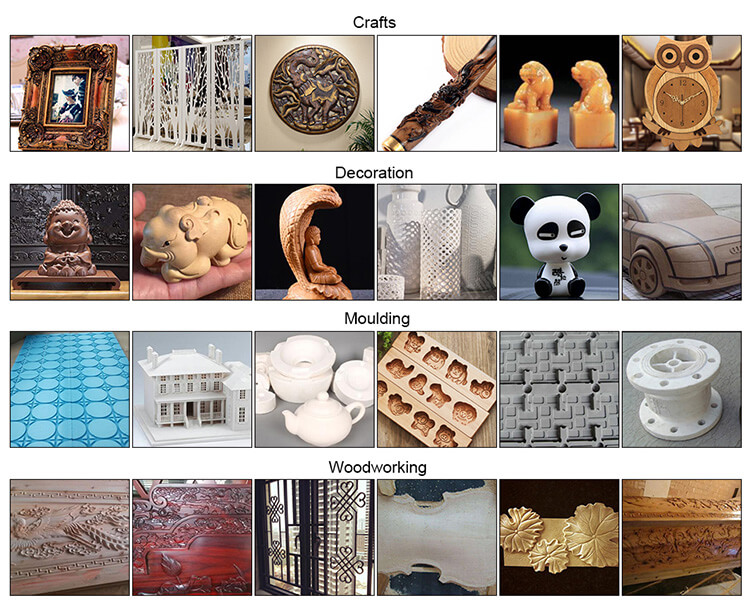

Wood CNC Machine Functions:

- Cutting: Slicing through wood to create specific shapes and sizes.

- Carving/Engraving: Etching designs, patterns, or text onto the wood surface.

- Drilling: Creating holes with precise diameters and depths.

- Profiling: Shaping the edges of wood pieces with intricate designs.

Best Wood CNC Machine Types:

- 3-Axis CNC Machines: The most common type, which moves in three directions: X (left-right), Y (forward-backward), and Z (up-down).

- 4-Axis CNC Machines: Includes an additional rotary movement (A-axis) to rotate the workpiece.

- 5-Axis CNC Machines: Provides two additional rotary movements, offering greater flexibility and capability to create complex designs.

Wood CNC Machine for Small Business Advantages:

- Precision: Highly accurate cuts and carvings that are difficult to achieve manually.

- Efficiency: Faster production times and the ability to handle complex tasks with ease.

- Consistency: Repeatedly produces identical pieces with minimal variation.

- Versatility: Can be used for a wide range of applications, from simple cuts to intricate engravings.

Best Wood CNC Machine for Small Business Applications:

- Furniture Making: Creating components like legs, arms, and detailed carvings on furniture pieces.

- Cabinetry: Cutting and assembling cabinet parts with precise dimensions.

- Sign Making: Engraving text and designs onto wooden signs.

- Art and Craft: Producing intricate designs and patterns for artistic projects.

FAQ

Q1: What are the key benefits of using a wood CNC machine for small businesses?

A wood CNC machine offers several benefits for small businesses in the woodworking industry. It allows for precise and accurate cuts, reducing material waste and improving overall efficiency. CNC machines also enable businesses to take on complex projects with ease, expanding their capabilities and attracting more customers. Additionally, these machines automate the cutting process, saving time and labor costs.

Q2: Are wood CNC machines suitable for beginners?

Yes, many wood CNC machines are designed with user-friendliness in mind, making them suitable for beginners. These machines often come with intuitive software interfaces and step-by-step guides, allowing users to learn and operate them with ease. However, it is still recommended to undergo some training or seek assistance from experienced users to maximize the machine’s potential.

Q3: Can wood CNC machines work with different types of wood?

Yes, wood CNC machines can work with various types of wood, including hardwoods, softwoods, and even engineered wood products. The cutting speed and feed rate may vary depending on the type of wood being used, but CNC machines are generally capable of handling different wood materials effectively.

Q4: What maintenance is required for wood CNC machines?

Wood CNC machines require regular maintenance to ensure optimal performance and longevity. This includes cleaning the machine’s components, such as the spindle, rails, and bearings, to remove dust and debris. It is also essential to lubricate the moving parts and check for any signs of wear or damage. Following the manufacturer’s guidelines and scheduling routine maintenance will help keep the machine in excellent condition.

Q5: Can wood CNC machines be upgraded or expanded in the future?

Yes, many wood CNC machines offer upgrade options and compatibility with additional accessories. This allows businesses to expand the capabilities of their machines as their needs evolve. It is essential to consider the upgrade options and compatibility of a CNC machine before making a purchase, especially ifyou plan on scaling your business in the future.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.