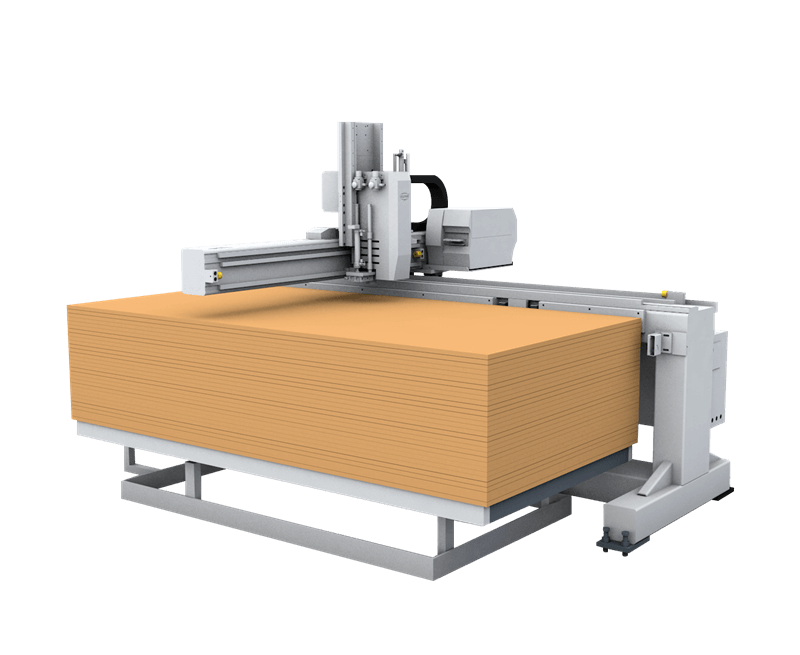

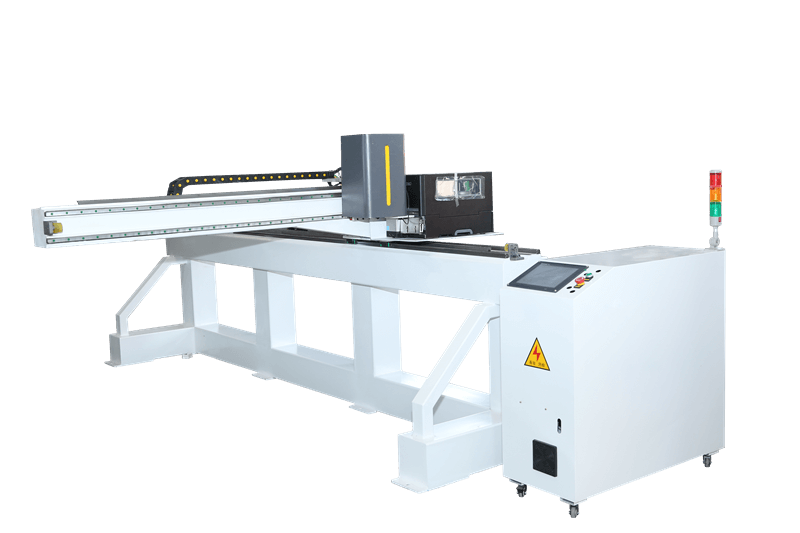

ATC Nesting CNC Machine with Automatic labeling System and Printer

The machining center is equipped with saw blade spindle, linear tool changer, and automatic loading and unloading platform. With automatic labeling system, it can help improve efficiency and reduce labor costs.

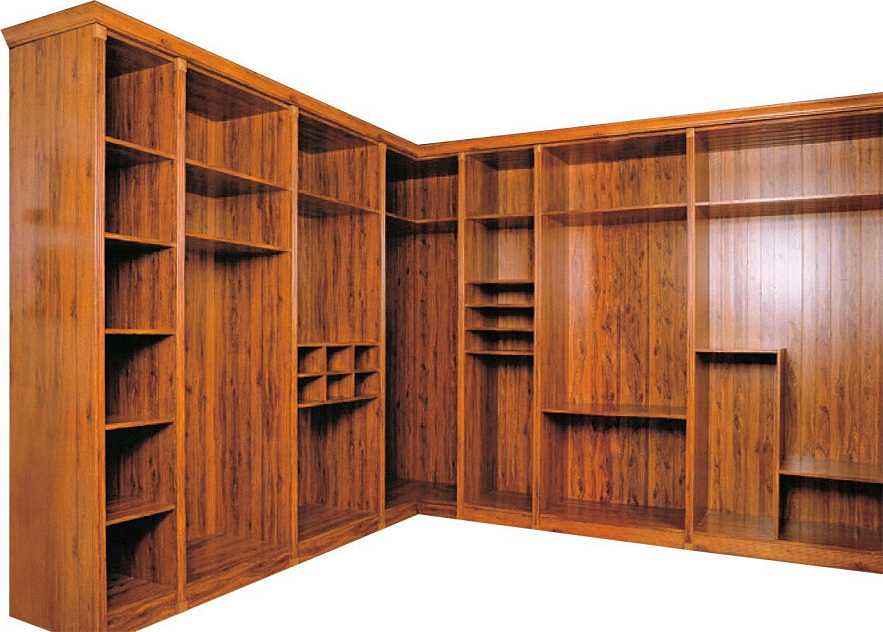

Nesting CNC machine is a type of panel furniture production line, which is a smart CNC solution for customized furniture production like panel furniture making, cabinet door making, closet door making, home door making, wardrobe making, home decoration making, cabinets making, home furniture making, shop and office furniture making.

Nesting CNC Machine iGC-LT Video

ATC Nesting CNC Machine Parameter

| Model | iGC-LT / iGC |

| Working area | 1220*2440*250mm |

| Spindle | 9KW Air cooling spindle |

| Inverter | Fuling |

| Motor | Servo motor |

| Syetem | TAIWAN Syntec |

| Table | Double Vacuum absorbed table |

| Guide rails | 25 Taiwan HIWIN |

| Cabinet | Independent cabinet |

| Vacuum pump | 7.5KW water cooling pump |

| Voltage | AC 380V-50HZ |

We offer customized services according to your requests such as the working area and specifications.

Automatic feeding platform

Auto feeding materials, automatic layout optimization, improve material utilization. Save working time: Automatic feeding, save the time of labor, no human intervention, minimizing error rate to minimum, ensure the quality of the order.

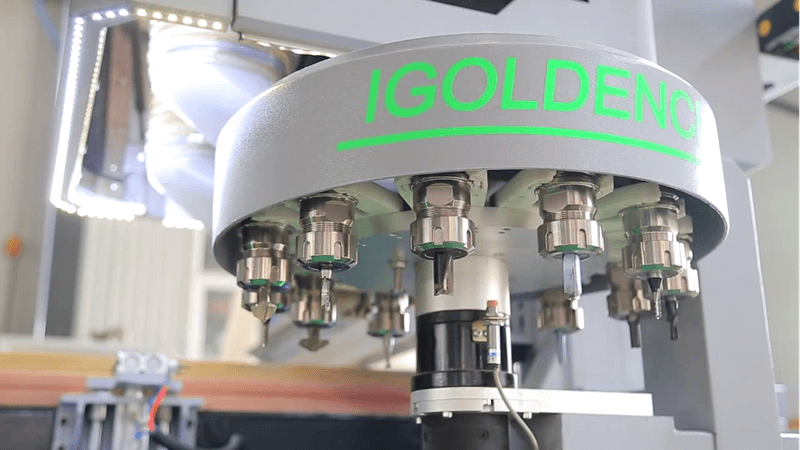

Automatic Tool Change

With 12 high-speed disc tool magazines, tool change can be completed within 8 seconds, which effectively improves production efficiency.

Automatic labeling system

With an automatic labeling function, the machine can quickly recognize the workpieces’ position and conduct precise processing.

Syntec 6MB control system

These is a USB port on the controller, so you can transfer files through the USB port.

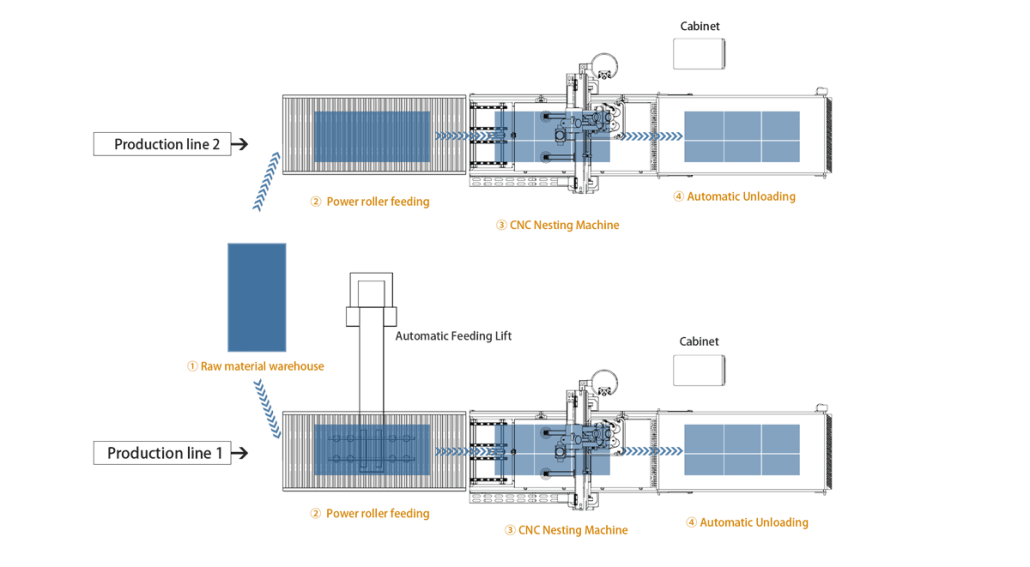

(Option) Automatic loading unloading system

Highly automated discharge solution with automatic loading and unloading system. The entire work cycle of loading, nesting, drilling, and unloading is performed automatically, thereby achieving the highest productivity and zero downtime,it can effectively improve the production efficiency of cabinets and panel furniture.

CNC Machining Center Application

>Production and processing of various types of furniture:Wood Furniture Industry: Wave Plate, fine pattern, antique furniture, wooden door, screen, craft sash, composite gates, cupboard doors, interior doors, sofa legs, headboards and so on.

>Wooden door and furniture decoration industry: solid wood and composite door, cabinet door, large-area plate carving, solid wood, panel furniture carving, solid wood art mural carving, etc .;

>Wood products processing: clocks, electrical countertops, sporting goods and equipment;

>Musical instrument industry: three-dimensional curved surface and shape cutting of sculptable musical instruments;

>Crafts industry: photo frames, jewellery boxes.

Contact Us Today to Get Price!

The nesting CNC machine is a computer numerical control equipment specially designed for the production of panel furniture line. It is also known as CNC nesting machine for sale, furniture making machine, CNC router nesting near me, nesting CNC router for furniture, furniture manufacturing machine, cabinet CNC machine, kitchen cabinet door making machine, CNC machine for cabinet making, cabinet door machine for sale, etc.

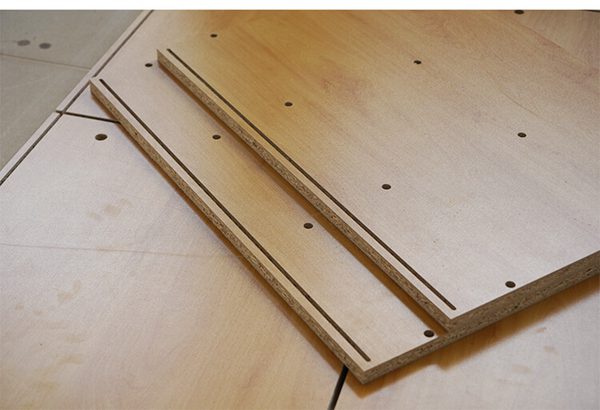

Nesting CNC machine is mainly used to cut various wooden works. Generally, through the design of intelligent software, the nesting CNC routers can automatically optimize the typesetting design and generate the effect map. Besides, the nesting machine can also perform operations such as modification intuitively, and automatically generate various paths. Therefore, it can save sheets and improve sheet utilization. The nesting CNC machine is widely used in the furniture industry such as cabinet doors, wardrobe doors, solid wood doors, paint-free doors, solid wood composite doors, and suite doors. If you are a manufacturer of furniture production lines, this nesting CNC machine is definitely one of your indispensable CNC equipment.

High end automatic CNC nesting machining center is used in home decorations, office furniture, wardrobe, cabinets, and more custom panel furniture making. Now the nesting CNC machining center for sale at affordable price.

- Good effect of processsing: High precision, cutting material very smoothly, Automatic design, automatic classification.

- With intelligent, humanization, and high automatic operation, the nesting CNC wood router machine can make the operator much more easier for handling all, any people can learn in couple hours for operating, it can save cost of labor.

- Improve work efficiency: Auto feeding materials, automatic layout optimization, improve material utilization.

- Save working time: Automatic feeding, save the time of labor, no human intervention, minimizing error rate to minimum, ensure the quality of the order.

- Leading brand components such as Italian HSD spindle (automatic tool change), Japanese Yaskawa servo motors, Taiwan Syntec controller, Apex reducer and transmissions ensure high efficiently.

- Double layer vacuum table can hold small pieces for excellent cutting, realize all kinds of customaries cabinet.

Production Workshop