Atc CNC Router With Automatic Tool Changer

ATC CNC Router Video

ATC CNC Router For Wood Parameter

Technical Data

| Working Area | 1300*2500/ 1500*3000/2000*3000/2000*4000mm |

| Z Axis Height | 250mm |

| Positioning Accuracy | 0.03mm |

| Re-positioning Accuracy | 0.02mm |

| Body Structure | Heavy-duty Welding Body |

| X, Y AxisStructure | Linear Guide Rail,Gear Rack |

| Z AxisStructure | Linear Guide Rail,Screw |

| Max. Running Speed | 50000mm/min |

| Max. Working Speed | 30000mm/min |

| Spindle | 9.0kw Air-cooling Spindle |

| Spindle RPM | 24000rpm/min |

| Working Voltage | AC 220V/ 380V,50-60Hz |

| Machine Weight | 1800/2000/2300/2500kg |

If you need more detailed information, please inform us as soon as possible.

Features of Linear ATC CNC Wood Router:

1. Welded structure by thick profiled steel stabilized under high temperature, ensures minimum distortion, excellent rigidity and powerful strength.

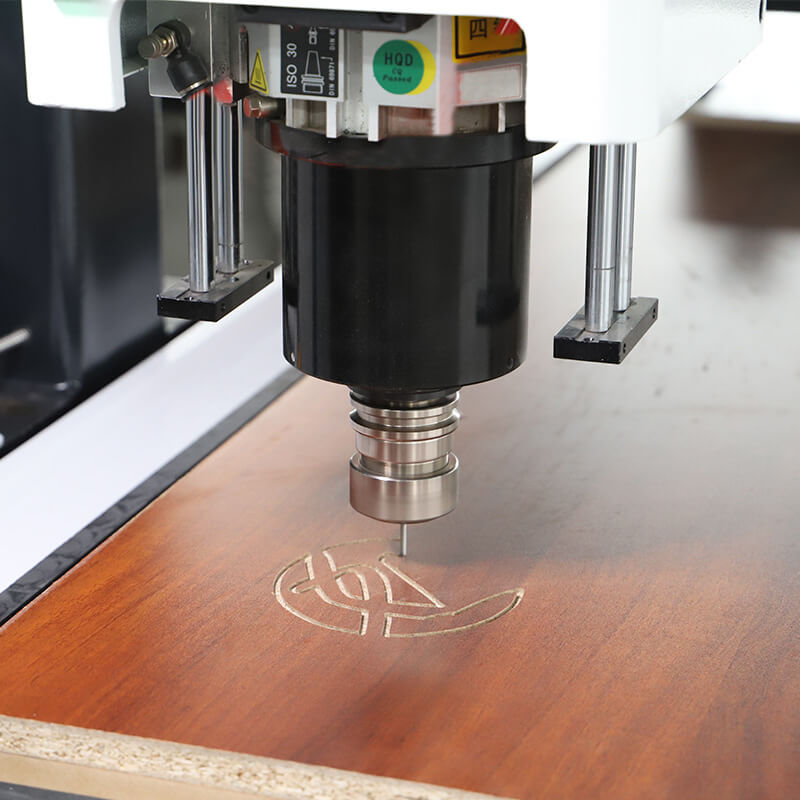

2. Italy HSD spindle makes machine with high precision and long service time and stable movement.

3. Configured with imported tool magazine of 8 tools the machine can change tools speedy and freely. Changing tools in 8 seconds.

4. Tool sensor enables the machine compensate the tolerance of the tool length.

5. Strong power suction of Yongdun free-oil pump.

6. Imported Taiwan SYNTEC control system, separated keyboard control, color LCD display add machine more versatility.

7. Strong dust collector ensures site cleanliness during the machine operation.

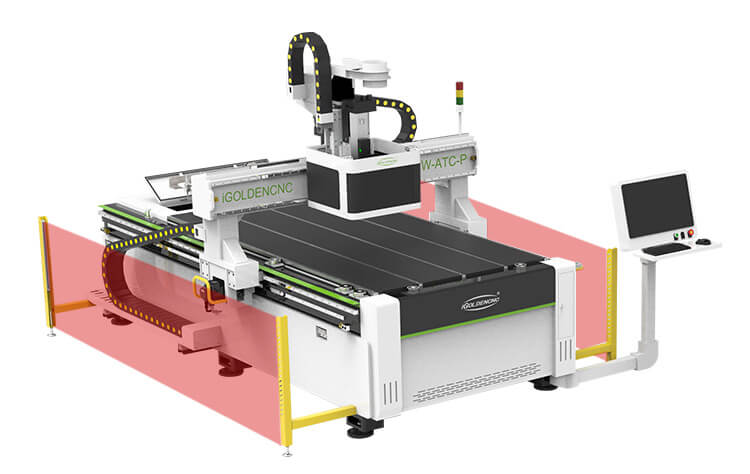

ATC CNC Router with automatci tool changer

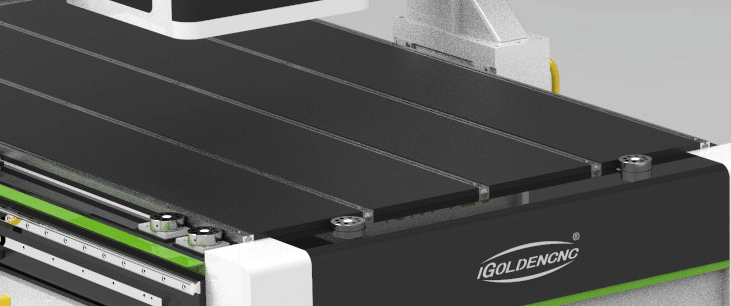

With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.Vacuum table using high-density material with great suction strength, comfortably accommadating all sizes of work piece.

21 inch screen-Integrated cabinet

Taiwan Syntec control system

Integrated cabinet Easy to coordinate, can be rotated to a suitable position for operation

T-slots are added inside and outside the workbench.

Grating safety protection

In order to avoid damage to man and machine, optional grating protection device.

Application

Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

- Cabinets and Furniture. Sign Making and Carving Musical Instruments

- Plastic and Foam Marble and Stone Engraving Prototyping and 3D modeling

- Metal Fabrication and Steel Applications Exhibits and Scene / Prop Shops Architectural Millwork Aluminum and Brass Machining

Wood CNC Router ATC FAQ

- Automatic Tool Changing

- Efficiency: Automatically switches tools during a job, reducing manual intervention and machining time.

- Versatility: Allows for complex machining tasks requiring multiple tool types without stopping the machine.

- Precision and Accuracy

- Tolerance: Achieves very tight tolerances, often within thousandths of an inch.

- Repeatability: Ensures consistent results across multiple pieces.

- Versatility

- Materials: Capable of working with wood, plastics, composites, aluminum, and other soft metals.

- Applications: Ideal for cabinetry, furniture making, sign making, mold making, and 3D carving.

- Automation

- Efficiency: Automates repetitive tasks, reducing manual labor and increasing productivity.

- Complex Designs: Executes intricate designs that would be difficult or impossible to achieve manually.

- Software Integration

- Design Software: Compatible with CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) software.

- User Interface: Often includes a user-friendly interface for designing and controlling operations.

- Safety Features

- Enclosures: Some models include safety enclosures to contain dust and debris and protect the operator.

- Emergency Stops: Equipped with emergency stop buttons to quickly halt operations if needed.

- Frame/Base

- Material: Usually constructed from heavy-duty steel or aluminum for maximum stability and durability.

- Function: Provides a solid foundation, minimizing vibrations to ensure precise cutting.

- Worktable/Bed

- Material: Often made from aluminum or steel, sometimes equipped with a vacuum table for secure material holding.

- Function: The surface where the workpiece is secured during machining.

- Gantry

- Structure: A robust bridge that spans the width of the machine, supporting the spindle.

- Function: Moves along the X-axis, enabling the spindle to traverse the length and width of the workpiece.

- Spindle

- Function: The motorized component that holds and rotates the cutting tools.

- Speed: Variable speed options to suit different materials and cutting conditions.

- ATC System

- Tool Magazine: Holds multiple cutting tools (commonly 6 to 20 tools).

- Tool Holder: Mechanism that securely holds each tool in place.

- Tool Changer: Automated system that swaps out tools from the spindle as needed during the machining process.

- Stepper/Servo Motors

- Function: Drive the precise movement of the X, Y, and Z axes.

- Types: Stepper motors for accuracy and cost-effectiveness; servo motors for higher precision and speed.

- Control System

- Components: Includes a computer, CNC software, a control panel, and electronic controllers.

- Function: Converts design files (usually CAD/CAM) into instructions (G-code) that control the machine’s movements and tool changes.

- Cutting Tools

- Variety: A range of router bits (end mills, ball nose bits, V-bits, etc.) for different cutting, drilling, and carving tasks.

- Material: Typically made from carbide or high-speed steel for durability and precision.

The cost of an ATC CNC router can vary greatly depending on a variety of factors. These factors include the machine’s specifications, features, brand reputation, build quality and size of the work area. In addition, geography and local market conditions can also affect pricing. Here are some general guidelines:

- Entry-level models: Small and lead-screw ATC CNC routers with limited features start at about $8,000 to $10,000.

- Mid-range models: A standard-sized ATC CNC router with moderate tool capacity and additional features may cost between $15,000 and $30,000.

- High-end models: High-end ATC CNC routers are equipped with advanced features, larger work areas, and powerful spindles, and can cost $60,000 or more. Some industrial-grade models can even exceed $100,000.

It’s worth noting that these are rough estimates and prices may vary based on the following factors:

- Brands And Manufacturers: Well-known and reputable manufacturers may offer pricier machines, but they usually have better build quality, support, and features.

- Size And Work Area: Larger CNC routers with larger work areas tend to be more expensive.

- Tool Capacity And Features: Machines with higher tool capacity and advanced features such as automatic tool measurement, tool breakage detection and dust removal systems may be more expensive.

- Spindle Power And Speed: Machines with more powerful spindles or variable speeds may cost more.

- Control Systems And Software: CNC routers with complex control systems and software compatibility may have a higher price tag.

For accurate and up-to-date pricing, it is recommended to contact the CNC router manufacturer or dealer directly, as prices may change and new models with updated features may be introduced. Additionally, when evaluating the cost of an ATC CNC router based on your specific needs, consider long-term benefits and return on investment.

Contact Us Today to Get Price!

Reviews