ATC CNC Router with Pinch Roller Wood Working Machine

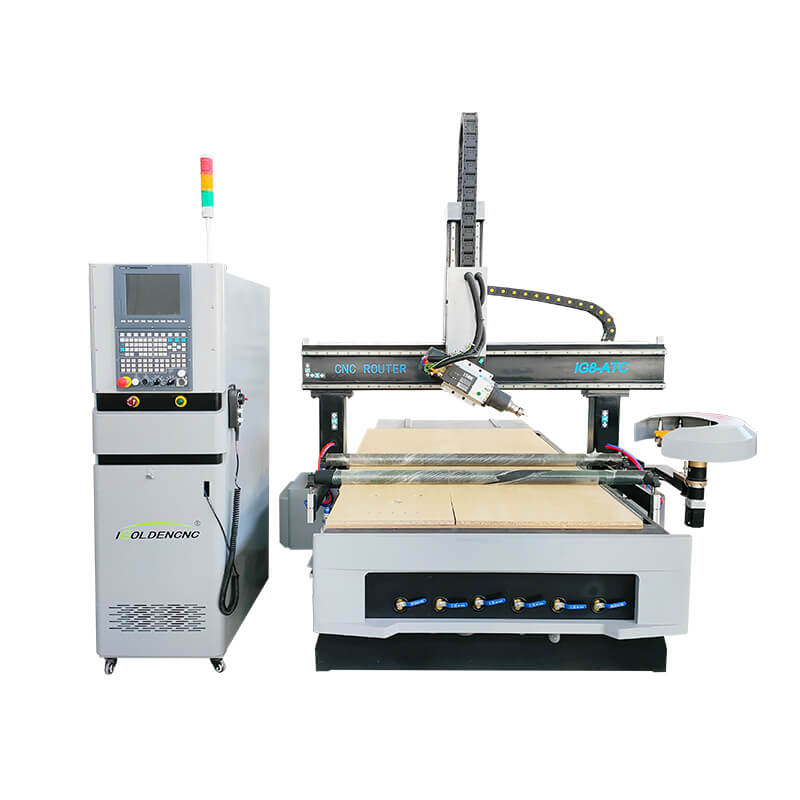

This machine brings superior flexibility in routing single sheet, stacked sheet, small part, large part, and rollers engaged or disengaged. This machine combines the capability of multiple CNC machines into one. Its compact design makes it a space saver thus allowing installation in small areas. Equipped with 2 rollers on either side of the cutting spindle(s) it automatically holds down the warped sheet stock or stacked sheet by extending & retracting rollers as they roll off. It is available in cast-iron fixed bridge moving table design (similar to our S-Series) and twin table moving gantry design (similar to our Pro Series) ensures efficient material handling, and also a continuous triple table moving gantry design. It has a standard choice of flow through or dedicated spoil board to suit your requirement.

1325 ATC CNC Router Video

Atc Cnc Router Wood Carving Machine Parameter

| Model | 1325 ATC CNC Router |

| Working area | 1300*2500*400mm |

| Spindle | Italy HSD ATC 9KW air cooling spindle |

| Inverter | Fuling |

| Motor | Japan Yaskawa servo motors |

| Driver | Japan Yaskawa servo driver |

| control System | Taiwan Syntec 11MB control system |

| Table | Vacuum & T-slot table with air cooling pump |

| Oil lubrication | Automatic lubrication |

| Limit | Omron limit |

| Transmission | XY axis helical rack Z axis Taiwan ball screw |

| Rail | X, Y, Z axis Taiwan HIWIN 25 Square guide rail |

| Screw | Z axis TBI 3210 ball screw |

| Bed | Thick steel welded big square tube |

| Gangry | Strong frame |

| Pillars | Steel pillar(Suitable for high-end customers) |

| Cabinet | Independent cabinet |

| Voltage | 3 phase/380V |

| Color | As requirement |

| Tools | 1 box (10 pieces) |

If you need more detailed information, please inform us as soon as possible.

Atc Cnc Router Wood Carving Machine Features

Automatic tool changer for cnc router uses a professional CNC motion control system, it can directly support G code and PLT code formats generated by various CAD/CAM software such as Type3, MASTERCAM, CASMATE, Art CAM, AUTOCAD, UG, CorelDraw, etc. The control system software is based on the Microsoft Windows operating system, which has the advantages of simple, reliable operation and easy to learn.

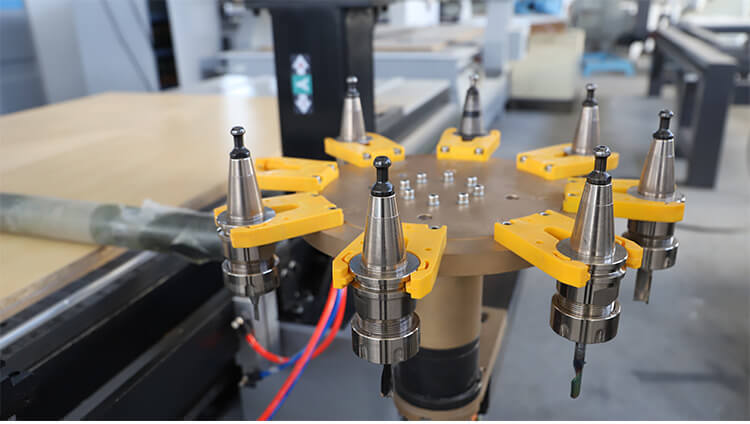

In-line tool change tool magazine

With 8 or 12 sets of tools to change automatically, which can saving time of tools changing and improving working efficiency.There are two tool change modes for inline tool change and disc tool change. Widely used, including engraving, milling, chamfering, side milling, drilling, cutting, grooving, etc.

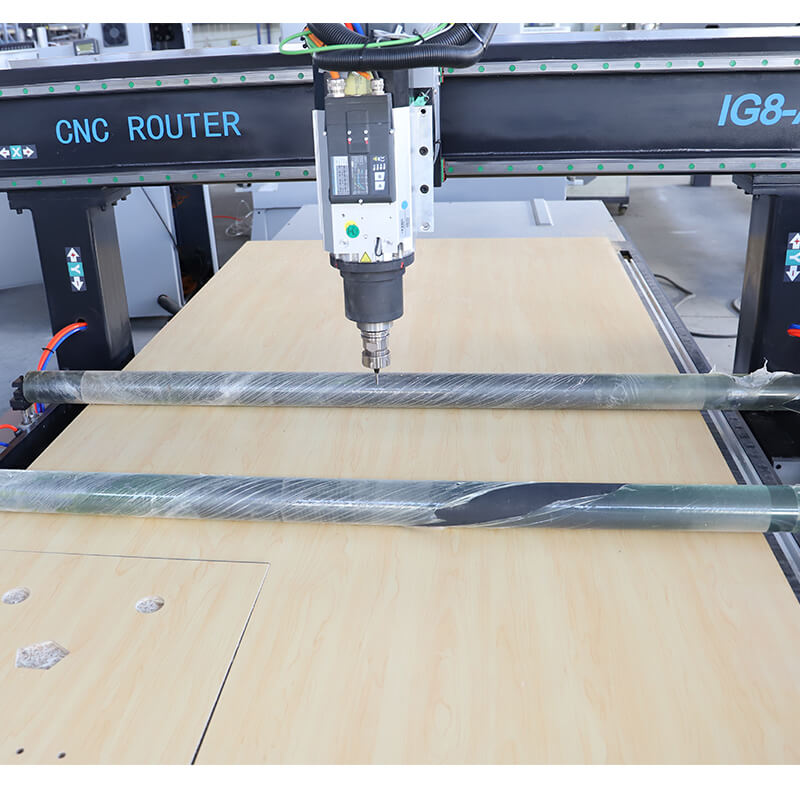

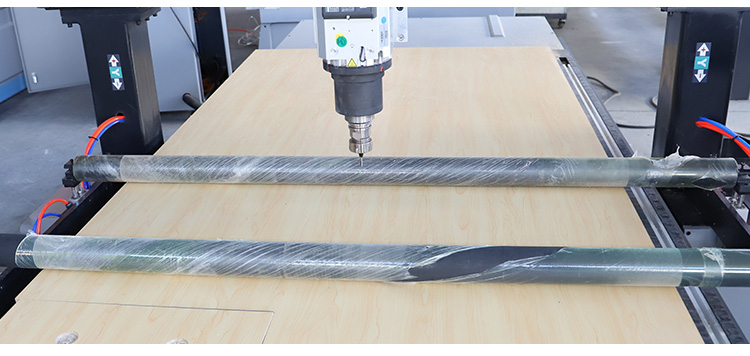

Pinch Roller

Two pressure roller can fix the material on the table to make the engraving process more accurately. it automatically holds down the warped sheet stock or stacked sheet by extending & retracting rollers as they roll off.

Rotary spindle. Swing +-90 degree, very suitable for carving 3d wood sculpture or wooden toy or car plane moulds;

Controller System

Design: The interface adopts the international standard G code command, which is compatible with domestic and foreign engraving, and the operation is simple. High quality, reasonable price and economical.

Application

Wooden furniture industry: solid wood and composite doors, cabinet doors, sliding doors, paint-free doors, lacquered doors, soft-packed doors, flat panel carving, solid wood carving, panel furniture processing, antique mahogany furniture processing, solid wood mural carving and other industries;

Advertising industry: acrylic, PVC, MDF, artificial stone, plexiglass, plastic, copper, aluminum and other soft metal plates.

Contact Us Today to Get Price!

An ATC or Automatic Tool Changer is made use of in CNC router machines so that their tool carrying capacity and productivity may be increased. By quickly changing the tools, it reduces the amount of time that the CNC machine is idle and allows for easy working with various tools.

Once a tool change command is received by the machine, the tool that needs to be changed will come to the fixed ‘tool change position’ of the machine. Then, the arm of the Automatic Tool Changer will pick up the tool from this position. The arm has a gripper on each side that shifts between the magazine and turret. One gripper picks up the old tool from the turret position while the other picks up the new tool from the magazine. A 180° rotation is then done to place the tools into the desired position.

Woodworking industry: Processing of three-dimensional wave board, cabinet doors, solid wood doors, craft wooden doors, paint-free doors, screens, craft window, and auxiliary processing of shoe polishers, game machine cabinets and panels, mahjong tables, computer tables and panel furniture.

Advertising industry: Advertising signage, logo making, acrylic cutting, plastic molding, and processing of various advertising materials and decorative products.

Mold industry: It can engrave copper, aluminum, iron and other metal molds, as well as artificial marble, sand and stone, plastic plates, PVC pipes, wooden boards and other non-metal molds. Craft gift industry: It can carry out a variety of shadow carvings, reliefs, and widely used in crafts industry.

- Enquiry. Feel free to tell us what material you want, what is your max working size and what product you want to do. The budget is also welcome.

- Free Quotation provided. We will send our quotation sheet with machine configuration, photos, videos and prices to you according to your request.

- Launch the order. Your company will arrange the deposit, and we start the machine production from 3D design, machine body welding, machining, painting spare parts preparing, manufacture and inspection.

- Testing sample video and delivery. After our manufacture and inspection, we will make a final video of the machine working for you.

- After the confirmation, the machine will be shipped by sea through my or your agent. After-sale service. We will provide a video teaching program to tell the customer how to use or install our machine. And my service team will 7*24 hours online to answer customer questions.

- Feedback. We are expecting feedback from our customers. Please tell us how you feel about machine quality and service. If you have more ideas to help us improve, that will be very appreciated.