ATC CNC Router

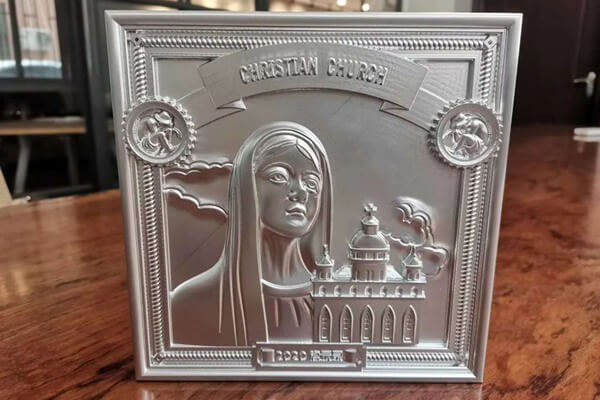

ATC CNC router machine has two types of tool magazines: linear and carousel. Both of them can be installed beside the spindle or on the side of the machine bed. By changing different tools automatically, the ATC CNC machine can complete multiple and complex woodworking processes at one operation. It can realize cutting, carving, engraving, drilling, routing, grooving, and pocketing of wood, MDF, acrylic, PVC, plastic, foam, stone, soft metal and other materials. It is also called ATC CNC wood carving machine, wood engraving machine. Basic type 3 Axis ATC CNC can be upgraded to be 4 Axis, 5 Axis, Routary type, etc.

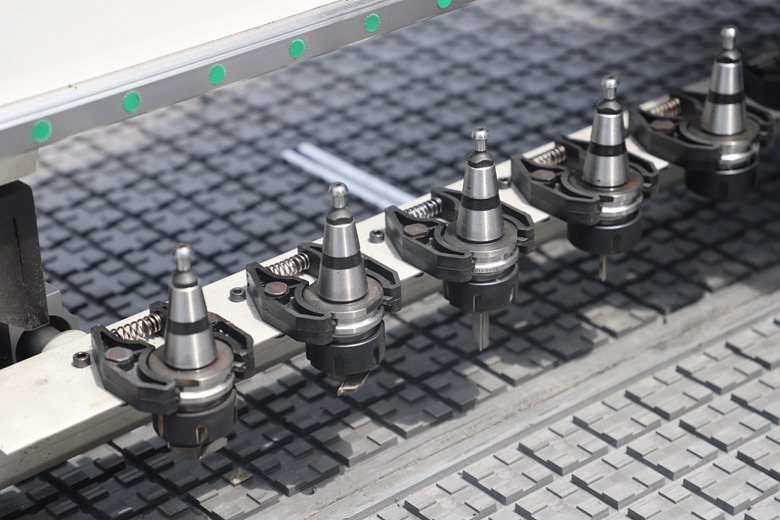

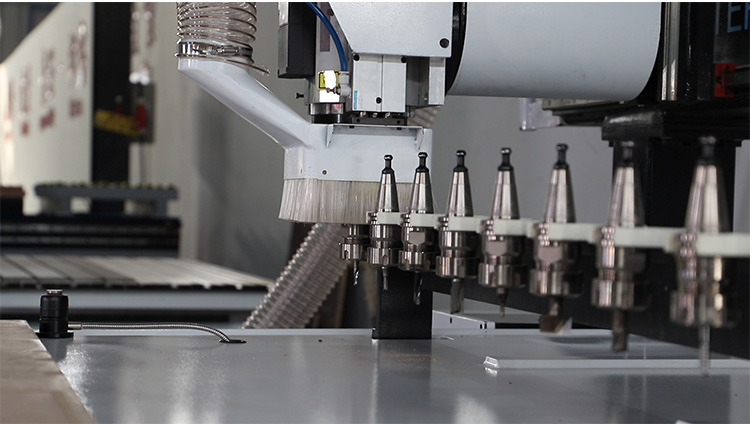

There are two kinds of tool changing type for the ATC CNC router.

1. Straight line tool changer, economical and practical. The tool bank is installed in the bottom of gantry, the tools handle is arranged side by side, and all the tools are put out by the tool bank. The tool is selected by the spindle to save a suit of motor and drive device. The system can use three-axis system.

2. Disc tool changer, the tool bank is installed on the spindle or gantry side, choosing the suit bit by rotating the disc tool bank which is driver by servo motor. The tool bank and its span is small, and more stable. It needs another sets of servo motor and drive. The system needs four axis system.