CNC router wood engraving machine is a computer-controlled cutting and engraving tool specifically designed for woodworking applications. It utilizes a spindle or router bit to carve, cut, and engrave designs on wooden surfaces, such as wooden doors.CNC router wood engraving machines can work with different types of wood, including solid wood, plywood, MDF (Medium-Density Fiberboard), particleboard, and other wood-based materials. The machine’s cutting parameters, such as spindle speed and feed rate, can be adjusted based on the specific wood type and desired engraving depth.

CNC Router Wooden Door Design Making Machine

CNC wood door router design making machine features

1) Designed for customized furniture, panel-type furniture, customized closet cabinet production, it has cutting, drilling, grooving and other processing functions, improves efficiency, save material and labor.

2)-Simple operation: installed with automatic typesetting software, simply enter sheet size to automatically optimize the layout, workers can easily operating this machine after 3-5 hours training.

3) Machine frame is heat treated after welding to remove any welding stress or tension.

4) Safety light sensor system using three light beams protecting the operator standing at the front of the machine and 1800mm high safety fences at both ends and across the rear of the machine.

When selecting a CNC router wood engraving machine for wooden doors, consider factors such as machine size, cutting area, spindle power, controller capabilities, software compatibility, and the specific engraving requirements of your wooden door designs.

Wooden Door ATC CNC router

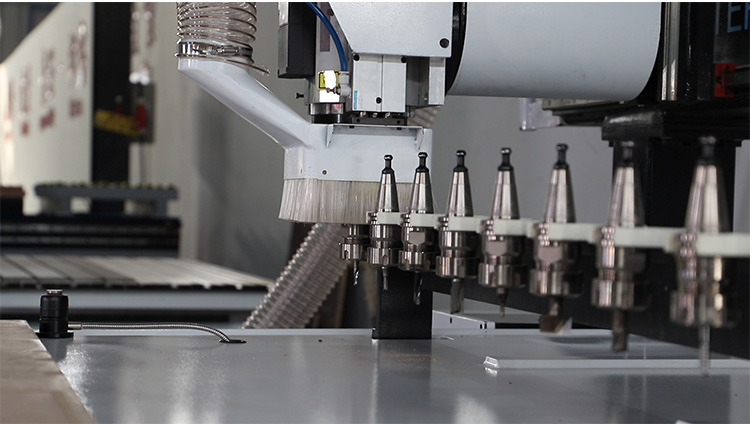

ATC CNC router is a type of CNC machining center with automatic tool changer kit that changes router bits in the tool magazine automatically instead of manual operation based on different designs for cabinet making, door making, furniture making, crafts making, decorations, musical instruments, sign making, windows, tables, and most popular woodworking projects & plans. The spindles usually carry tool magazines with 4, 6, 8,10, or 12 router bits and cutters. The tools can automatically change according to the working requirements when the machine works, no need of manual operation. You will meet three most common types of ATC CNC router kits, which include linear ATC CNC kits, drum ATC CNC kits (rotary ATC CNC kits), and chain ATC CNC kits.

Automatic Tool Changer is a device for transferring, loading and unloading tools between the spindle and the tool magazine. Automatic Tool Changer is the full name of ATC in CNC machining.

Automatic tool changer kits drive the CNC machine with continuous working, that is, after each process is completed, the new tool used in the next process is automatically changed to the spindle, and the spindle picks up the tool, the exchange of tools is generally completed by the coordinated action of the manipulator, magazine and spindle.

Compared with multi spindle CNC routers, ATC only needs one spindle in the headstock, the spindle components have sufficient rigidity to meet the requirements of various precision machining. In addition, the tool magazine can store a large number of tools for multi-step machining of complex parts, which can significantly improve the adaptability and machining efficiency of the machine tools. The ATC system consists of two parts: a tool magazine and an automatic tool change device. It has two major advantages: the first is that only one spindle is reserved, which is beneficial to simplify the structure of the spindle and improve the rigidity of the spindle; the second is that a large number of router bits with different types and functions can be stored in the library, which is convenient complete various complex and multi-step processing procedures.

Automated tool changer kit is composed of tool magazine, tool selection system, tool exchange mechanism and other parts, and the structure is more complicated. It is responsible for transferring the bit between the magazine and the spindle, pushing the bit to be used to the spindle, and then sending the replaced bit back to the magazine inside. Although this changing method is not as straightforward as the previous one, it avoids the magazine and spindle from moving for tool change, and is replaced by an automated tool changer. In this way, the movement range of the mechanical components is reduced, the changing is completed faster, and the design layout is also more flexible.

Wooden CNC Router Machine

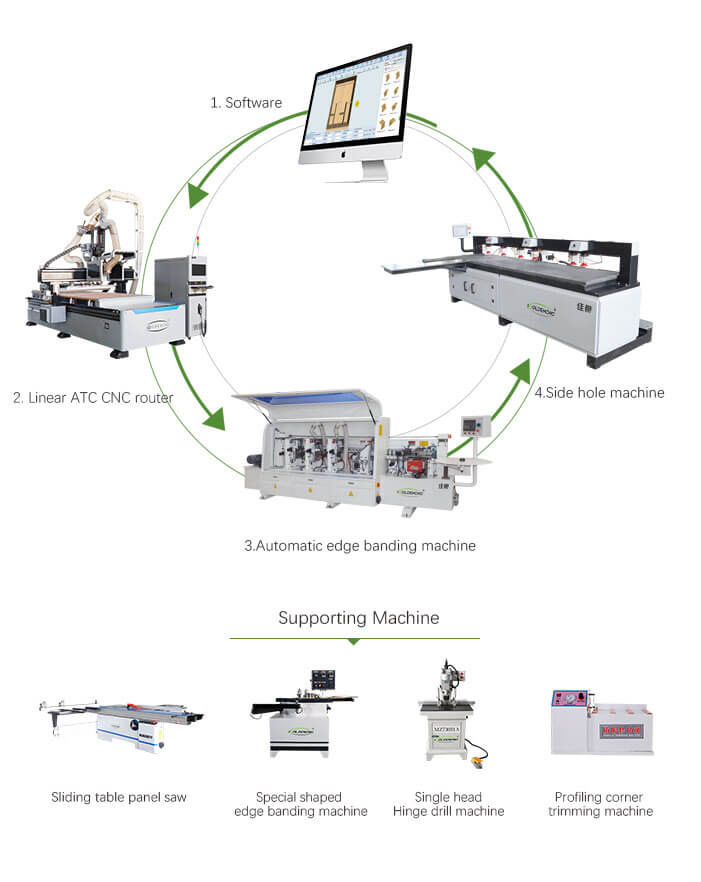

Nesting CNC machine is a smart machine tool in customized panel furniture production including cabinet door making, closet door making, home door making, wardrobe making, home decoration making, cabinets making, home furniture making, shop and office furniture making. In the production process, the operator just as porters, the Intelligent CNC nesting machines can realize automatic paste barcode, automatic feeding, drilling, slotting, cutting, automatic uploading, automatic retrieval processes for cutting side hole, slot on the back, back hole, the whole process don’t need human judgment, automatic processing, get rid of the dependence of woodworking professional and technical workers.

Besides, automatic feeding CNC nesting machine instead of the traditional push table saw or precision saw, to prevent the occurrence of work-related injuries, the health of employees is guaranteed.

Kitchen Cabinet Door Making CNC Router Machine

The CNC router for cabinet making relates to a four process double station double pusher material opening machine. The feeding machine consists of a working bench, which is equipped with a two working table along the length direction of the platform support at the top of the workbench support, and there is a Y moving mechanism above the bench bracket. The two transverse symmetrical Y to the rack in the Y moving mechanism is fixed on both sides of the platform bracket, and the transverse beam in the moving mechanism at the Y. The top is fixed with a X direction rack with a transverse setting of X to the moving mechanism, and a Z direction moving mechanism on the left side of the moving mechanism along the direction of the feeding, and the Z to the driving motor in the Z moving mechanism is fixed vertically on the X slide plate in the X to the moving mechanism, and the Z direction slide plate in the Z moving mechanism is equipped with a processing device. The opening machine can make maximum use of the working time of the opening machine, high processing efficiency, convenient feeding and unloading, and can avoid the droop of the drag chain. The cabinet making CNC router is suitable for kitchen cabinet making, cabinet door making, corner cabinet making, decorative cabinet making, home cabinet making, wall cabinet making, wood cabinet making, base cabinet making and other custom cabinet making in bathroom, garage, living room, and office.

Features of CNC Router for Wood Door Making

1. The four air-cooling spindles of the CNC router for cabinet making can automatic finish the vertical hole drilling, slot cutting, carving in one step.

2. The CNC router for cabinet making has advantages of saving time, labor and materials, replace traditional CAD draftsmen, splitting men, cutting men, only need 8 minutes to input size design and split. Automatic layout optimization, improve material utilization. High quantity automatic design, Automatic type setting, no human intervention.minimizing error rate to minimum, ensure the quality of the order.

3. High efficiency: Double table for cabinet making, when finish one work line, it can auto work on another table, greatly improve the work efficiency.

4. Drive Faster: Two motor driving on Y axis, Fast speed, high efficiency, Max Air move speed to 60m/min.

5. Operation Steadily: The best linear square guide, double row and four row ball slider, large loading capacity. Convenient operation, high precision, long life time.

6. Intelligent control: It adopts the original computer control system, has a break point, power outages, has the function of re-carving after break point and power failure.

7. Sturdy Durable: Heavy T type of lathe bed, strong rigidity, big strength, smooth rotation, speed for a long time not deformation, not shake.

8. Independently electric control box with perfect wiring and free moving pulleys.

Cabinet making CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

If you have an idea to get the full automatic CNC solutions for cabinet door making, you can check from the Customized Cabinet Furniture Solutions or send an inquiry to us with your detailed requirements for cabinet door making plans.

Wooden Door Making CNC Router Machine Application

1. Advertising and gift making industry CNC router nesting machine is used to carve all kinds of two-color plate signs, plexiglass, 3D billboards, two-color figure statues, embossed medals, organic plate embossing, 3D door characters, etc.

2. Model and mold making industry Sand table models, house models, engraving button relief mold, printing bronzing mold, injection mold, stamping mold, shoe mold, plastic light box mold, etc.

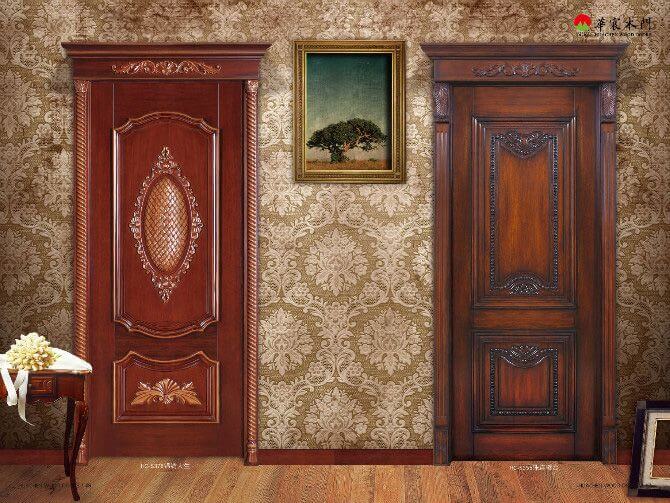

3. Woodworking industry Wood nesting machine (also named as the machine for furniture production) can make classical mahogany furniture products, wave boards, 3D engraving craftsmanship, and embossed pattern designs.

4. Automotive industry Processing of tire mould, lamp mould, and car interior decoration, etc. 5. Aluminum cutting industry Aluminum plate, aluminum-plastic plate, aluminum honeycomb panel, aluminum profile, etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.