CNC stone fabrication equipment has revolutionized the stone industry, offering unparalleled precision, efficiency, and versatility. These machines are essential for creating intricate designs, custom shapes, and high-quality finishes in stone fabrication projects. This comprehensive guide explores the different types of CNC stone fabrication equipment, their benefits, applications, and how to choose the right machine for your needs.

Stone Fabrication Equipment

CNC stone fabrication equipment refers to computer-controlled machines used to cut, shape, and finish stone materials. These machines use advanced software to control their movements, ensuring precise and consistent results. CNC technology has significantly improved the efficiency and accuracy of stone fabrication processes, making it possible to create complex designs and high-quality finishes.

Types of CNC Stone Fabrication Equipment

CNC Bridge Saws

CNC bridge saw are versatile machines used for cutting large stone slabs into smaller pieces. They feature a movable bridge that supports the cutting head, allowing for precise and efficient cuts. Bridge saws are commonly used for cutting countertops, tiles, and other large stone pieces.

CNC Routers

CNC router are used for shaping and detailing stone surfaces. They can create intricate designs, edge profiles, and decorative elements. CNC routers are ideal for custom stonework, such as creating detailed countertops, backsplashes, and architectural elements.

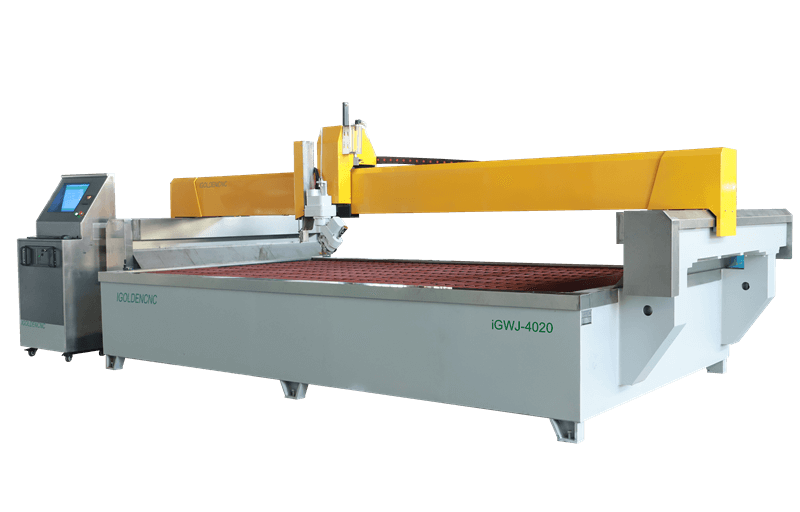

CNC Waterjet Machines

CNC waterjet machine use a high-pressure stream of water mixed with abrasive particles to cut through stone. These machines offer exceptional precision and can cut intricate designs and shapes with smooth edges. Waterjet machines are suitable for cutting various types of stone, including granite, marble, and quartz.

CNC Milling Machines

CNC stone milling machine used for shaping and finishing stone surfaces. They can create complex shapes, grooves, and patterns with high precision. Milling machines are ideal for creating custom stone pieces, such as sculptures, architectural elements, and decorative panels.

CNC Engraving Machines

Stone CNC engraving machine are used for etching designs and text onto stone surfaces. They can create detailed engravings with high precision, making them ideal for creating custom signage, memorials, and decorative elements.

How Does CNC Stone Fabrication Equipment Work?

The process of fabricating stone with CNC equipment involves several key steps:

- Design Creation: Using CAD (Computer-Aided Design) software, create or import the design for the stone piece.

- Toolpath Generation: Convert the design into a toolpath using CAM (Computer-Aided Manufacturing) software.

- Machine Setup: Secure the stone slab on the machine’s bed and select the appropriate cutting parameters.

- Fabrication: Load the toolpath into the CNC machine and start the fabrication process. The machine follows the programmed instructions to cut, shape, and finish the stone.

- Finishing: Inspect the fabricated piece and perform any necessary finishing touches, such as polishing or sealing.

Benefits of Using CNC Stone Fabrication Equipment

Precision and Accuracy

CNC stone fabrication equipment offers exceptional precision and accuracy, ensuring consistent and high-quality results. The computer-controlled movements eliminate human error, resulting in perfectly fabricated pieces every time.

Efficiency and Speed

These machines can operate at high speeds, significantly reducing production time. The automation of the fabrication process allows for continuous operation, increasing overall productivity.

Versatility

CNC stone fabrication equipment can handle a wide range of materials and applications. Whether you’re cutting, shaping, or engraving, these machines offer the versatility needed for various stone fabrication projects.

Customization

CNC technology allows for full customization of stone pieces. You can create intricate designs, custom shapes, and detailed finishes that match your specific requirements.

Material Efficiency

CNC machines minimize material waste by producing precise cuts and shapes. This efficiency is particularly beneficial when working with expensive stone materials.

Applications of CNC Stone Fabrication Equipment

CNC stone fabrication equipment is used in various applications, including:

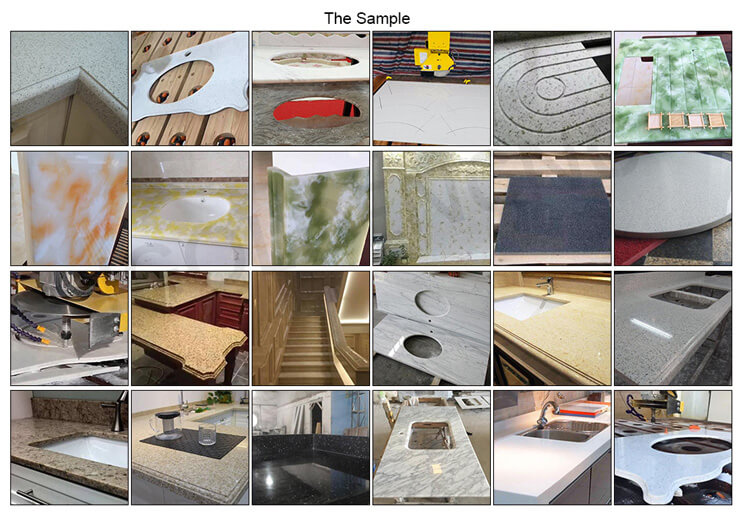

- Countertops: Creating custom countertops with intricate designs, edge profiles, and sink cutouts.

- Tiles: Cutting and shaping tiles for flooring, walls, and backsplashes.

- Architectural Elements: Fabricating custom architectural elements, such as columns, balustrades, and cornices.

- Sculptures: Creating detailed stone sculptures and art pieces.

- Signage: Engraving custom signs and memorials with detailed text and designs.

- Decorative Panels: Producing decorative panels and inlays for interior and exterior applications.

Considerations When Choosing CNC Stone Fabrication Equipment:

- Material Compatibility: Ensure the equipment can handle the specific types of stone you work with.

- Size and Capacity: Match the machine’s size and cutting capacity with the dimensions of the stone slabs you typically use.

- Software Integration: The equipment should be compatible with CAD/CAM software for designing and programming the cuts.

- Maintenance and Support: Consider the availability of maintenance services and support from the manufacturer or supplier.

- Budget: Balance the initial investment cost with the long-term benefits and potential return on investment.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.