In recent years, the woodworking industry has witnessed a revolution with the introduction of 3D Computer Numerical Control (CNC) routers. These powerful machines have transformed the way woodworkers approach their craft, opening up a world of possibilities for creativity and precision. In this guest post, we will delve into the fascinating realm of 3D CNC routers for woodworking and explore their myriad benefits and applications.

CNC Router is more and more popular for furniture, door, cabinet woodworking areas and advertising fields in the world due to its wisdom, intelligent, fast speed and high working efficiency.

3D CNC Router for Wood

A 3D CNC router is a computer-controlled cutting machine that utilizes advanced software and motorized tools to carve intricate designs, shapes, and patterns into wood. Unlike traditional woodworking techniques, which require manual labor and are prone to human error, 3D CNC routers offer unparalleled precision and efficiency.

The introduction of 3D CNC router has revolutionized the woodworking industry, empowering artisans, designers, and woodworkers to push the boundaries of creativity and precision. These machines offer unparalleled accuracy, time and cost efficiency, as well as incredible versatility and flexibility. As the woodworking industry continues to evolve, 3D CNC routers will undoubtedly play a vital role in shaping its future.

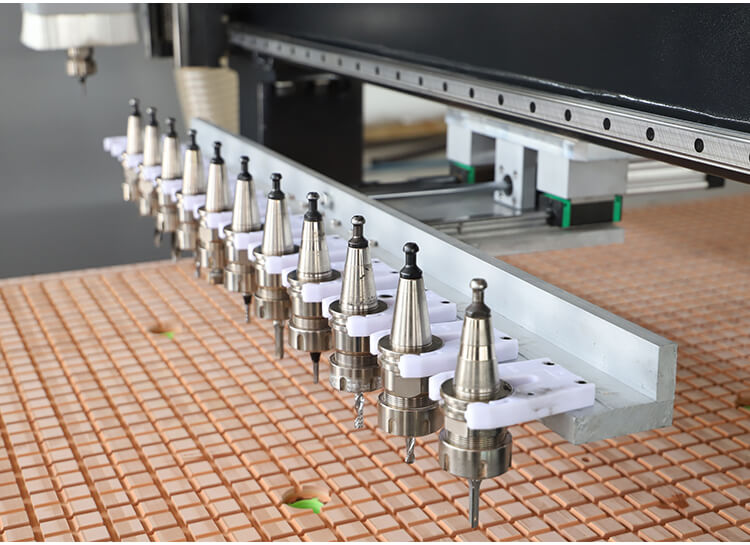

The choice of cutting tools is crucial for achieving desired results with a 3D CNC router. Different types of cutting tools, such as end mills, ball nose cutters, and V-bits, offer varying levels of precision, surface finish, and material compatibility. Woodworkers should consider the specific requirements of their projects and select cutting tools accordingly.

How Do 3D CNC Routers Work?

These routers operate by following pre-programmed instructions known as G-code. The G-code commands guide the machine to move the cutting tool along multiple axes (usually three or more) with exceptional accuracy. The result is a highly precise and repeatable carving process that can produce intricate designs and complex geometries.

3D Wood CNC Machine

- Heavy-duty construction designing with aging treatment. It can be used for a long time without deformation and guarantees high performances.

- With imported spindle and drill from Italy, screw rack from Germany, linear rail from Taiwan, IGOLDENCNC router machine is suitable for gravity cutting at a very high stage of stable performance.

- The control interface is more humanized and is easy to operate. Instead of skilled workers, the operator can work after simple training with high speed and efficiency lead to high yield.

- Optional automatic loading and unloading. IGOLDENCNC router machine can load and unload automatically, cut wooden boards optimally, drill vertical holes in once time. Uninterrupted processing achieves output maximum efficiency. Compared with traditional cutting, it can save a lot of labor costs. It only needs one person to operate, even one person can operate several devices with zero error, simple operation, and high efficiency.

- World-famous brand spare parts. IGOLDENCNC router adopts Taiwan ball screw, Germany Igus cable, Germany heroin racks, Italy HSD spindle, France Schneider electrics, Germany Siemens controller, driver and so on.

- Heavy-duty machine body with reasonable structured double-deck multi holes table with strong adsorption.

Advantages of 3D CNC Router for Wood

Precision and Accuracy

One of the most significant advantages of 3D CNC routers is their ability to achieve unparalleled precision and accuracy. These machines can consistently reproduce intricate designs with intricate details, ensuring uniformity across multiple pieces. Woodworkers can now execute complex projects with ease, confident in the precision of their final products.

Time and Cost Efficiency

By automating the cutting and carving process, 3d cnc router machine significantly reduce production time and labor costs. These machines work tirelessly, operating around the clock if necessary, allowing woodworkers to increase their output without compromising quality. Additionally, the elimination of human error and rework reduces material wastage, resulting in cost savings.

Versatility and Flexibility

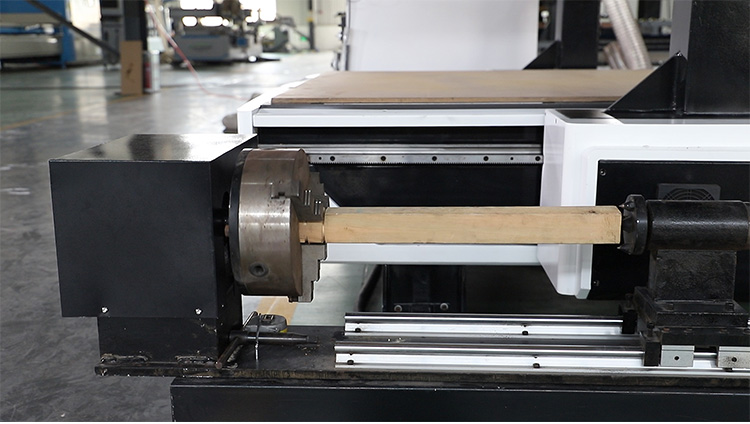

3D CNC router offer exceptional versatility, enabling woodworkers to explore a wide range of design possibilities. From intricate engravings and detailed reliefs to complex joinery and custom furniture components, these machines can handle it all. The ability to create complex three-dimensional shapes and contours opens up a world of creative possibilities for artisans and designers.

Applications of 3D CNC Router for Wood

Furniture Design and Production

3d cnc wood router have revolutionized furniture design and production. Woodworkers can create custom furniture pieces with intricate details and complex shapes, pushing the boundaries of traditional design. CNC technology allows for the efficient production of prototypes, enabling designers to iterate and refine their creations swiftly.

Sign Making and Engraving

Sign makers and woodworkers specializing in engraving have embraced 3D CNC routers for their ability to create stunning and detailed signage. These machines can engrave text, logos, and graphics onto wood surfaces with exceptional precision, resulting in eye-catching signs for businesses, events, and personal use.

Architectural Millwork

Architectural millwork, including intricate moldings, columns, and decorative elements, can be produced with utmost precision using 3d cnc wood router. The ability to replicate complex designs consistently allows for the creation of visually stunning and historically accurate millwork for restoration projects or high-end custom homes.

The world of 3D CNC routers for woodworking is dynamic and ever-evolving. By carefully selecting the right machine, understanding the workflow, prioritizing safety, and staying abreast of emerging trends, woodworkers can harness the full potential of these powerful tools. With their precision, efficiency, and versatility, 3D CNC routers continue to transform the woodworking industry, empowering artisans and designers to bring their imaginative creations to life.

What are the advantages of 3D CNC machine for sale?

1. Improve production efficiency: CNC lathe 4 axis machine can be programmed to reduce human interference in specific manufacturing processes. This helps reduce production time, thereby ensuring increased production efficiency.

2. Simplify work: The process performed manually by operators using traditional machines requires a lot of time and effort. These processes can be programmed using a CNC router 4 axis machine to simplify the operator’s work.

3. High precision: The best 4 axis CNC router can consistently produce precision workpieces. After confirming the programming control, 3D CNC wood router produced thousands of pieces in a short time.

4. Flexible processing: As the process is programmed, the 3D CNC wood carving machine is flexible. You can run a key program for a segment, save it, and then call it again when you need to clone the segment.

5. Easy to set up: CNC router machine 4 axis is easy to set up and easy to operate, which helps you save time and allows you to complete tasks on time effectively.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.