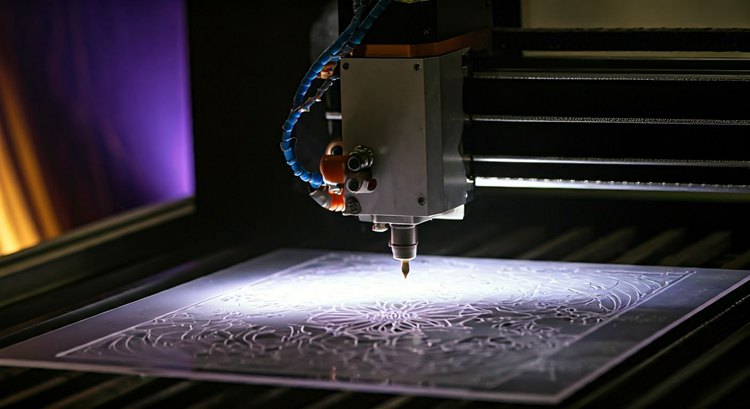

CNC routers are versatile tools that have revolutionized the manufacturing and crafting industries. Known for their ability to cut wood, plastics, and composites, many wonder if these machines can handle tougher materials like aluminium. The answer is a resounding yes, but with some caveats and considerations. This article delves into the intricacies of using a CNC router to cut aluminium, offering insights, tips, and best practices to achieve optimal results.

Can a CNC Router Cut Aluminium?

Yes, a CNC router can cut aluminium. However, it requires specific tools, settings, and techniques to ensure a clean and precise cut. Aluminium is a soft metal, making it easier to cut than steel, but its properties still pose unique challenges.

Challenges of Cutting Aluminium with a CNC Router

- Heat Generation: Aluminium tends to heat up quickly during cutting, which can lead to tool wear and material deformation.

- Chip Removal: The chips produced during cutting can clog the tool, reducing efficiency and precision.

- Tool Wear: Aluminium is abrasive, which can wear down cutting tools faster than other materials.

- Vibration: Improper settings or a lack of rigidity in the machine can cause vibrations, leading to poor cut quality.

Advantages of Using a CNC Router for Aluminium

- Precision: CNC routers offer unparalleled accuracy, making them suitable for intricate designs.

- Versatility: They can handle a variety of aluminium grades and thicknesses.

- Cost-Effectiveness: For small to medium-scale projects, CNC routers are more affordable than industrial milling machines.

- Ease of Use: With the right software and settings, even beginners can achieve professional results.

Tool Selection

-

Use a cutting tool designed for non-ferrous metals, particularly aluminium. Solid carbide end mills with two or three flutes are ideal, as they allow for better chip evacuation and prevent material from clogging the tool.

-

Look for end mills with a high helix angle, as this helps remove chips quickly, keeping the cutting edge clear and ensuring smoother cuts.

Feed Rates and Spindle Speeds

-

Aluminum requires a balanced approach to feed rate and spindle speed to avoid issues like melting or material buildup on the tool. Typically, use slower feed rates and higher spindle speeds compared to cutting wood.

-

Finding the ideal combination may require some adjustments, as too slow a feed can cause the material to stick, while too fast can lead to tool wear or a poor surface finish.

Lubrication and Cooling

-

Cooling is essential when cutting aluminium to prevent it from melting and adhering to the tool, which can damage the tool and ruin the cut.

-

Compressed air or mist coolant systems are commonly used for CNC routing aluminium, as they help to reduce heat buildup, improve surface finish, and extend tool life.

Chip Evacuation

-

Effective chip evacuation is crucial for aluminium machining. Use a vacuum or dust collection system to clear chips from the work area, preventing buildup around the cutting tool, which can cause clogging, poor surface finish, and tool wear.

-

Regularly clearing chips also reduces heat buildup, minimizing the risk of aluminium sticking to the tool.

Rigidity and Stability

-

Ensure that your CNC router has sufficient rigidity to handle the forces involved in cutting aluminium. Industrial-grade CNC routers are better suited for aluminium, as they are built to withstand these forces.

-

Lightweight routers may lack the stability needed for clean cuts in aluminium, resulting in vibration, deflection, and poor cut quality. If using a lighter router, consider reducing the depth of cut and feed rate to enhance stability.

Depth of Cut and Multiple Passes

-

For best results, use shallow depth cuts and make multiple passes rather than attempting a single deep cut. This approach reduces tool load, minimizes heat generation, and produces cleaner edges.

Common Applications of Aluminium Cutting with CNC Routers

- Prototyping: Creating prototypes for automotive, aerospace, and consumer products.

- Signage: Cutting aluminium sheets for custom signs and displays.

- Jewelry Making: Crafting intricate designs in aluminium for unique jewelry pieces.

- DIY Projects: Hobbyists use CNC routers for custom aluminium parts and decorations.

- Industrial Parts: Manufacturing small-scale aluminium components for machinery.

Aluminium CNC Router FAQ

1. Can all CNC routers cut aluminium?

Not all CNC routers are suitable for cutting aluminium. Machines with high-speed spindles, rigid frames, and proper tooling are better equipped for the task.

2. What type of aluminium is best for CNC routing?

Soft grades like 6061 and 5052 are easier to cut and provide good results. Harder grades may require industrial milling machines.

3. Do I need a special tool for cutting aluminium?

Yes, carbide end mills with single or double flutes are recommended for cutting aluminium. These tools are durable and efficient at chip removal.

4. How can I prevent tool wear when cutting aluminium?

Use proper lubrication, apply coolant, and select high-quality carbide tools. Additionally, optimize your feed rate and spindle speed.

5. Is it safe to cut aluminium with a CNC router?

Yes, it is safe if you follow best practices, use the right tools, and ensure proper machine setup. Always wear safety gear and monitor the process closely.

Conclusion

Cutting aluminium with a CNC router is entirely possible and can yield excellent results when done correctly. By selecting the right tools, optimizing machine settings, and following best practices, you can unlock the full potential of your CNC router for aluminium projects. Whether you’re a hobbyist or a professional, understanding the nuances of aluminium cutting will enhance your craftsmanship and expand the capabilities of your CNC machine.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.