In the realm of modern manufacturing and woodworking, CNC (Computer Numerical Control) routers have emerged as indispensable tools. Among the various types of CNC routers, the 3-axis CNC router holds a prominent position, a sophisticated piece of machinery that blends precision, versatility, and automation. From the delicate detailing of woodworking to the precise intricacies of industrial production, the applications of a 3-axis CNC router are as diverse as the materials it can manipulate.

3 Axis CNC Router

A 3-Axis CNC Router is a type of computer numerical control (CNC) machine used for precise machining and cutting operations on a variety of materials. The term “3-axis” refers to the machine’s ability to move in three directions: X (left/right), Y (forward/backward), and Z (up/down). This setup allows for accurate cutting, milling, drilling, engraving, and shaping of materials, making it ideal for a wide range of applications in woodworking, plastic, metalworking, and more.

Key Components of a 3-Axis CNC Router

A 3-axis CNC router is made up of several key components that work together to perform precise cutting, milling, and engraving tasks:

a) Controller

- The controlleris the brain of the CNC router. It receives the G-code instructions (which describe the desired cut or engraving) from the software and interprets them, directing the machine’s movements.

- It ensures that the X, Y, and Z axesmove to the correct positions and the spindle operates at the right speed and force.

b) Spindle/Motor

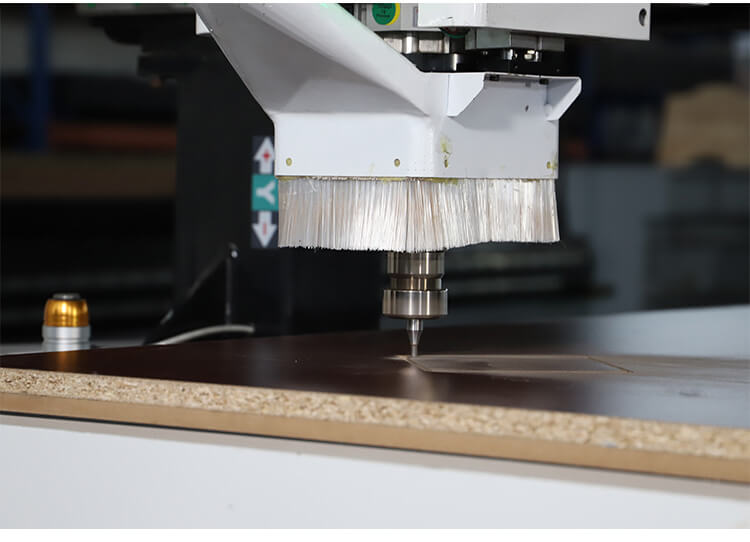

- The spindleis the part of the router that holds and rotates the cutting tool (such as a router bit, drill, or engraving tool).

- Spindle motor powercan vary from machine to machine, with more powerful motors used for harder materials like metal or thick wood. The spindle’s RPM (rotations per minute) also determines the cutting speed.

c) Linear Guides & Ball Screws

- The machine’s linear guides(rails) and ball screws allow the router’s components to move smoothly along the X, Y, and Z axes. Ball screws are important for reducing friction and ensuring high-precision movements.

- Some high-end machines use linear motorsor rack-and-pinion systems for even faster movement, although ball screws are still the most common.

d) Worktable

- The worktableis the surface where the material (wood, plastic, metal, etc.) is placed. It’s often equipped with vacuum hold-down systems or clamps to secure the material while cutting.

- Depending on the model, the table may be fixedor movable, and some larger machines have a multi-zone table to handle different sizes and types of material.

e) Tool Changer

- Many CNC routers include a tool changer, which allows the machine to automatically switch between different cutting tools (e.g., bits, drills, mills) without human intervention. This is essential for performing multiple different operations in one cycle.

- Some machines have a manual tool changewhere the operator manually switches out tools.

Types of 3-Axis CNC Router Applications

While 3-axis CNC routers are versatile, they are particularly suited for certain types of jobs:

a) Woodworking

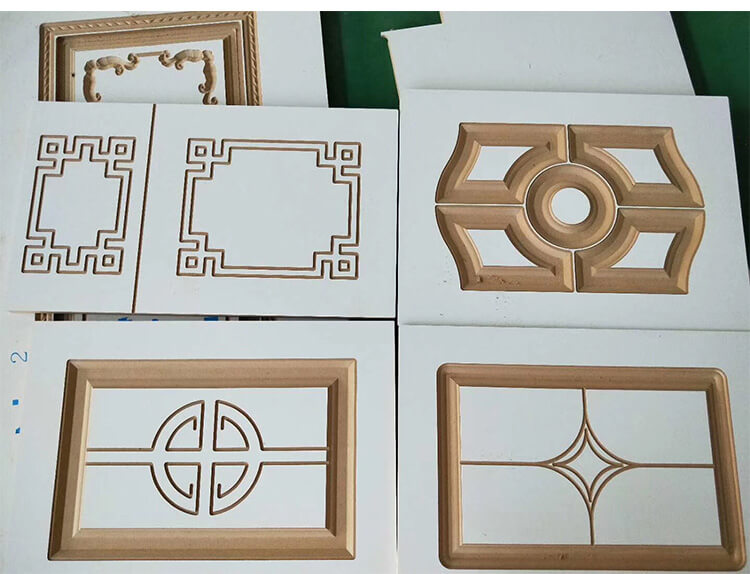

- Furniture Production: From carving intricate designs on furniture to cutting and shaping panels, CNC routers are used extensively in cabinetry and furniture production.

- Molding and Trim Work: CNC routers can cut custom molding profiles and shapes in wood and MDF.

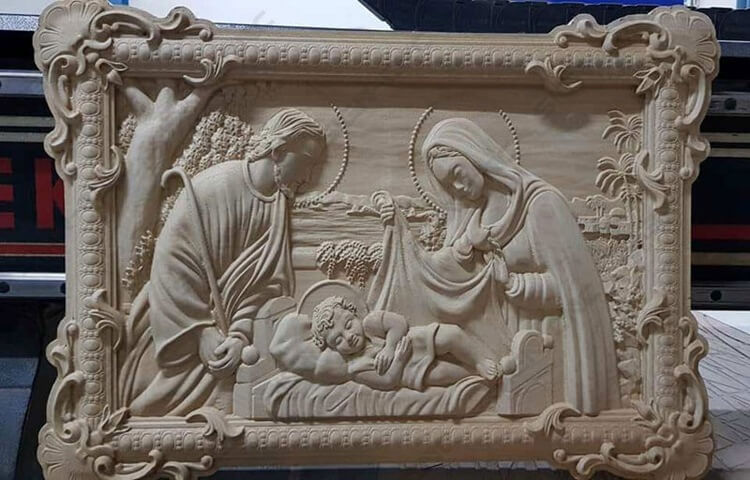

- Engraving and Relief Carving: They are used for engraving logos, text, and decorative relief carvings into wooden panels and signs.

b) Sign Making

- CNC routers are widely used in the signage industry to cut and engrave acrylic, PVC, foam, and other materials for custom signs.

- Dimensional Signs: 3D signs with layered or raised lettering are easily achievable with a 3-axis router.

c) Prototyping

- CNC routers are a popular choice for rapid prototyping, particularly in industries like automotive, aerospace, and consumer goods. They allow for fast creation of physical models from CAD designs.

- They can cut models from foam, plastics, and other materials used for prototyping.

d) Plastic and Composite Machining

- In addition to wood, 3-axis routers can handle various plastics (e.g., acrylic, PVC, HDPE) and composite materials.

- Precision Cutting: CNC routers can achieve highly detailed cuts on thin plastic sheets or thicker plastic parts.

e) Metalworking (Light Metals)

- Although not typically used for heavy-duty metalworking, a well-equipped 3-axis CNC router can machine light metalslike aluminum, brass, and copper.

- CNC routers are often used for creating light-duty parts, prototypes, and decorative engravings on metals.

Material Compatibility:

- Wood: Used extensively in furniture manufacturing, cabinetry, and signs.

- Plastics: Ideal for cutting and engraving acrylics, PVC, and other polymers.

- Foam: Often used in prototyping and model making.

- Aluminum and other soft metals: With appropriate tooling, a 3-axis CNC router can handle soft metals like aluminum.

- Composites: Can be used for cutting composite materials like MDF (medium-density fiberboard).

Advantages Of 3-Axis CNC Routers

Understanding the benefits and limitations of a 3-axis CNC router machine can help users make the right decision about their suitability for a specific project and industry. While these machines offer remarkable capabilities, careful consideration of their constraints ensures optimal utilization and successful implementation in various manufacturing and design scenarios. Here are some common advantages and limitations associated with 3-axis CNC routers:

- Precision and Accuracy: 3-axis CNC routers provide precise and consistent cutting or engraving, ensuring that each product is identical to the programmed design. These machines can achieve tight tolerances, making them suitable for tasks that require high precision.

- Versatility: 3-axis CNC routers can handle a variety of materials, including wood, plastic, metal, and composites. This makes them versatile for different industries such as woodworking, sign-making, prototyping, and more.

- Automation: The CNC control system automates the cutting process, reducing the need for manual labor and minimizing the chances of errors. This can result in increased productivity and cost-effectiveness for large-scale production.

- User-Friendly Programming: Integration with Computer-Aided Design (CAD) and Computer-Aided Manufacturing (CAM) software streamlines the programming process, making it more accessible to users with varying levels of expertise.

- Efficiency: CNC routers can operate continuously, allowing for efficient and uninterrupted production. They can operate continuously, 24/7 if needed, increasing productivity and reducing downtime.

- Complex Design Capability: The machines’ ability to follow complex toolpaths allows for the creation of intricate designs and fine detailing that may be challenging or impossible with traditional methods.

- Repeatability: Once a design is programmed, a 3-axis CNC router can reproduce the same design accurately and consistently, ensuring quality across multiple pieces. This is particularly beneficial for batch production or creating identical components.

- Reduced Material Waste: CNC routers optimize material usage by precisely cutting and shaping, minimizing waste, and contributing to cost-effectiveness.

- Multi-Tool Capabilities (Optional): Some advanced models come equipped with automatic tool changers, allowing the use of multiple tools without manual intervention, enhancing efficiency and reducing downtime.

How 3-Axis CNC Routers Work?

- Programming: Designs are created in CAD (Computer-Aided Design) software, specifying the dimensions, shapes, and tool paths. The CAM (Computer-Aided Manufacturing) software translates the CAD design into a set of instructions (G-code) that the CNC router can understand.

- Workpiece Securing: The material to be machined is securely attached to the CNC router’s table or bed.

- Tool Loading: The appropriate cutting tool is loaded into the spindle. Homing: The CNC router locates its starting position through a homing process.

- Toolpath Execution: The machine follows the programmed toolpath, moving along the X, Y, and Z axes to cut and shape the material.

What Should You Pay Attention To When Choosing A 3-Axis CNC Router?

After you understand the 3-axis CNC router through the above information, you can already make plans on whether to purchase this machine. Below we’ll go over the various factors you need to consider when choosing the right 3-axis CNC router to ensure the machine meets your specific needs and requirements. Here are key aspects to pay attention to when selecting a 3-axis CNC router:

- Machine Size: Consider the physical size of the CNC router, including the working area (X, Y, and Z axes). Ensure that it accommodates the size of the parts you intend to produce.

- Material Compatibility: Verify that the CNC router is suitable for the materials you plan to machine. Different machines are designed for various materials such as wood, plastics, metals, or composites.

- Spindle Power and Speed: The spindle is a critical component. Pay attention to its power (measured in horsepower or kilowatts) and speed (measured in revolutions per minute – RPM). The spindle should match the materials and cutting tools you intend to use.

- Accuracy and Precision: Check the machine’s accuracy and repeatability specifications. High precision helps achieve tight tolerances and produce precise parts.

- Drive System: The drive system, whether it’s a ball screw or rack and pinion, plays a role in the machine’s precision and speed. Choose a system that meets your requirements for accuracy and efficiency.

- Control System and Software: Evaluate the CNC controller and software. Ensure that it is user-friendly, supports the file formats you work with, and has the necessary features for your applications.

- Ease of Use and Programming: Consider the ease of use in terms of machine setup, tool changes, and programming. A user-friendly interface and straightforward programming can save time and reduce errors.

- Dust Collection System: If you’re working with materials that produce a significant amount of dust, choosing a good dust collection system can help keep your work environment clean and safe.

- Tool Changer Capability: If you plan to work on projects that require multiple tools, a tool changer can significantly improve efficiency by automating tool changes during the machining process.

- Rigidity and Construction: The sturdy and well-made machine maintains stability throughout the cutting operation. This contributes to the overall accuracy and quality of the machined parts.

- Availability of Support and Training: Understand the after-sales service items that CNC router manufacturers can provide. Reliable technical support is invaluable, especially when you encounter machine trouble and need help.

- Cost and Budget: Determine your budget and compare it with the features offered by different CNC routers. Consider the long-term value and return on investment (ROI) when making your decision.

- Reviews and Recommendations: Look for customer reviews and seek recommendations from others in your industry. Learning from the experiences of other users can provide valuable insights into the performance and reliability of a particular CNC router.

By carefully considering these factors, you can choose a 3-axis CNC router that aligns with your specific machining needs and business requirements.

The Future Trend Of 3-Axis CNC Routing

3-axis CNC routing will further develop with the advancement of technology. It becomes evident that the next era of CNC routing is not only about precision engineering but also about embracing a holistic approach that encompasses smart technologies, sustainability, and enhanced user experiences. Let us navigate through the emerging trends that are poised to sculpt the landscape of 3-axis CNC routing in the years to come.

- Advanced Automation: Increased automation and the use of robotics in CNC machining processes may continue to grow. This includes automated tool changes, part loading/unloading, and other tasks that enhance overall efficiency.

- Improved Software Capabilities: CAM software is likely to see continuous improvements, providing users with more advanced features for toolpath optimization, simulation, and toolpath verification. This could enhance overall programming efficiency and reduce errors.

- Materials and Cutting Technologies: Advancements in cutting technologies and the ability to handle a broader range of materials could open up new possibilities for CNC routers. This might include improved spindle technologies, tooling innovations, and the ability to work with advanced materials.

- AI and Machine Learning: Integration of artificial intelligence (AI) and machine learning algorithms could contribute to more intelligent machining processes. This may involve adaptive machining strategies, automatic parameter adjustments, and self-optimizing tool paths.

- Environmental Sustainability: There could be an increased focus on sustainability in CNC routing, with manufacturers exploring ways to reduce waste, energy consumption, and environmental impact. This might involve the use of eco-friendly materials and more efficient machining processes.

- User-Friendly Interfaces: The user interfaces of CNC routers may become more intuitive and user-friendly, making it easier for operators to program and control the machines. This could involve touchscreen interfaces, improved software workflows, and enhanced remote monitoring capabilities.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.