Today’s market requires cabinet manufacturers to use automation equipment and technology to not only gain a competitive advantage, but also to meet customer needs for time, cost, and creative decoration. So what is the best solution for cabinet making

Cabinet makers traditionally combine panel saws with the manual router, hand drills, point-to-point, or any combination of these items to produce cabinets. But sometimes you may find that it is easy to make mistakes, and then cause a waste of materials and time, increase losses.

How to Start a Cabinet Making Business

You need a CNC router made of a cabinet to complete the right work correctly and quickly!

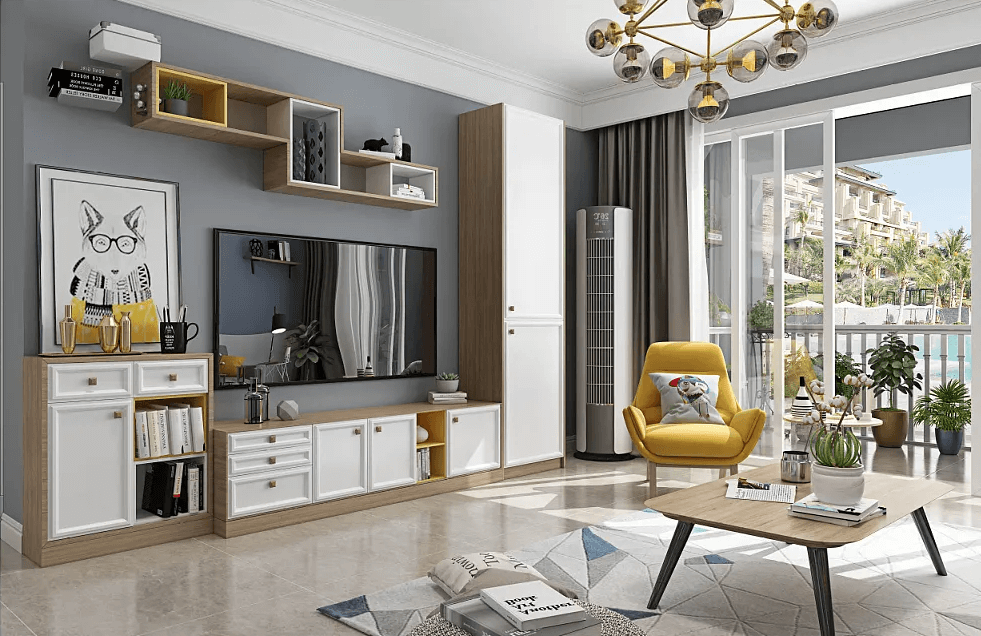

A well-designed cabinet door will give a new look to the decoration of a family kitchen. Therefore, it is particularly important for the processing of cabinet doors and furniture. Many carpenters or some furniture manufacturing factories will favor CNC machines to design exquisite cabinet doors and practicability, because computer-controlled Cabinet CNC machine has higher precision and maneuverability.

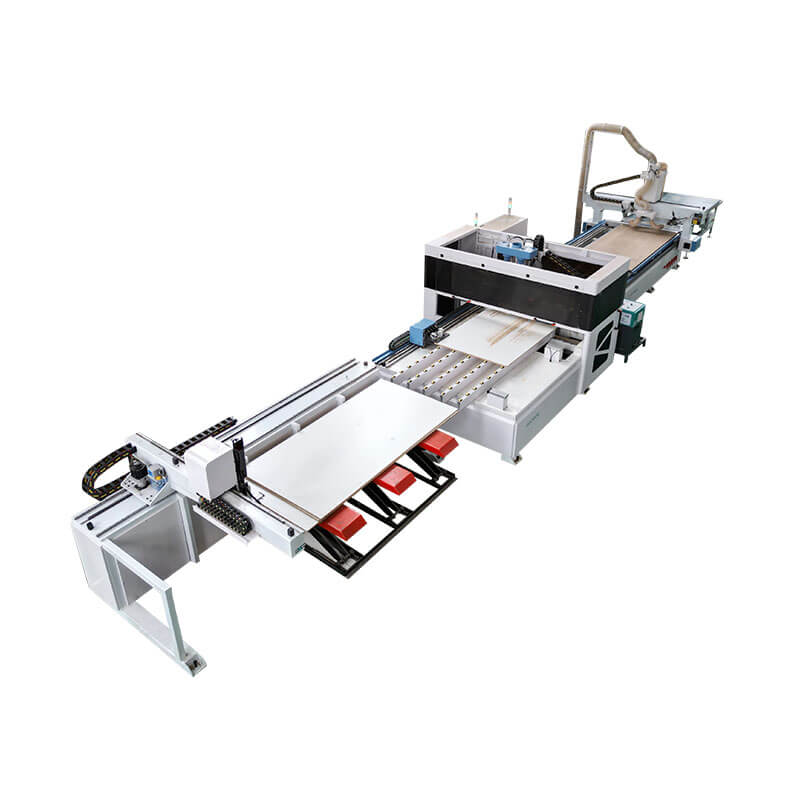

This Cabinet CNC machine launched by the IGOLDENCNC team in 2021 will be your best partner for making cabinet doors and furniture. The advantages of high precision, fast speed, automatic loading and unloading, automatic tool change, etc. are combined on the same Cabinet CNC machine. CNC kitchen cabinets saves time, has high production efficiency and good processing effect. The Cabinet door machine is the best choice for cabinet and furniture making manufacturers. Of course, Cabinet CNC machine has function of cutting and nesting. If you need, HSD aggregate heads of Cabinet CNC machine is options parts for your side hole boring working.

The industrial CNC wood router machine is the tool of choice for making cabinets. Whether you want to manufacture a set of one-off fully custom-designed cabinets, or needs need to design and build a system for a large number of unified cabinet production, we can meet your requirements.

We have helped thousands of cabinet manufacturers and woodworkers transform their shops. From traditional panel saws, manual milling machines, drills, and hand tools to successfully take full advantage of the huge advantages of CNC cabinet manufacturing.

Industrial CNC router machines are equipped with all the right tools and accessories to ensure efficient and clean processing of various materials. Cabinet manufacturers use all types of wood and fiberboard, in addition to certain plastics and aluminum based on applications and preferences. Recent trends refer to solid surfaces, recyclable, and more environmentally friendly materials.

Medium-density fiberboard, Plywood, blackboard, Melamine, hardwood, cork, Live edge wood, plastic products, Acrylic, Solid-surface material, etc.

What designs of cabinetry can I make using the Cabinetry CNC Router?

The CNC Cabinetry CNC Routers are fully-automatic Intelligent CNC Router machines. It finds many applications in the cabinet closet and door industries, as it has multi-functions for slotting, carving, milling, engraving, grooving, and cutting. It can be used to make entertainment units, frame/frameless cabinets, walk-in or reach-in closets, pantries, kitchen cabinets, peninsulas, and islands, among other things.

Advantages of the Cabinet Making Machine

- Reduce wasted work

The more waste that accumulates on your work floor, the more losses you will cause from wasted supplies. Since standard milling machines lack the precise control corresponding to CNC milling machines, errors in the workpiece are always a threat. Thanks to the computer operation, the CNC milling machine eliminated wasteful work caused by human error and produced thousands of identical parts without producing a single scrap. - Larger cutting range

For standard router planers, producing large products (such as stair risers) can be a challenge, especially in terms of accuracy. On the other hand, large CNC milling machines can easily produce such workpieces. If your woodworker moves in the direction of mass-produced parts with small errors, CNC wood milling machines are preferred. - Perfect repeatability

A CNC router controlled by a computer can produce hundreds of identical parts. For companies that value quality assurance, this aspect of CNC wiring is invaluable. - Easy to operate

Since standard routing involves physical operations that directly affect product quality and worker safety, standard routing requires extensive experience in addition to training. In contrast, the operation of a computer-controlled router is mainly based on computer training. This allows operators to gain expertise within a few months. - Increase production capacity

By producing a small amount of waste and operating with top-notch efficiency, industrial CNC milling machines can revolutionize production capacity. Compared to adding a standard router and hiring a technician to operate it, adding an industrial CNC router with a large cutting table can be extremely cost-effective.

The Best CNC Router for Cabinet Making

Application Of Kitchen Cabinet CNC Machine

This full-automatic Intelligent CNC Router for Cabinet closet door furniture production has multi-functions of carving, engraving, milling, slotting, grooving, cutting, chamfer edge.

Full automatic Intelligent CNC Router Machine is mainly used in the furniture making industry, especially cabinet closet and door industries.

- The Frame or frameless cabinet construction

- Entertainment units

- Kitchen cabinets, islands and peninsulas

- Closets: Walk-ins, Reach-ins, Entries, Pantries

- Angled and radius cabinets and countertops

- Vanities

- Bookcases

- Home office workstations

- Fine custom cabinetry… and much more

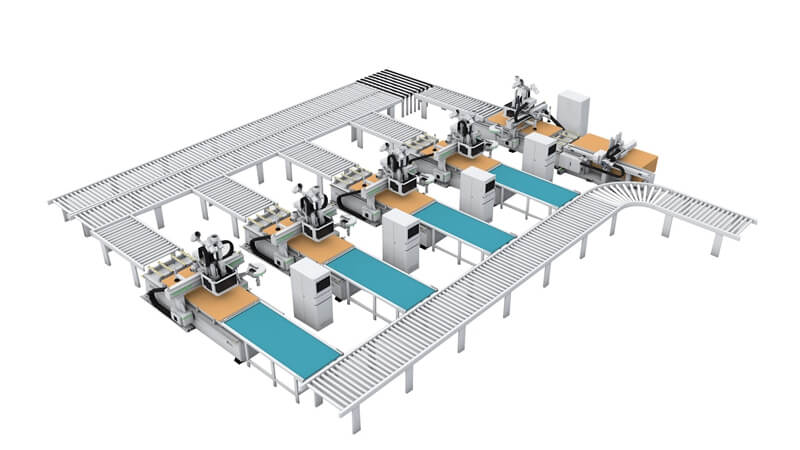

iGOLDEN provides multiple production lines for making cabinets, PVC doors, solid wooden doors, high-gloss cabinet doors, non-porous cabinets, etc. For example, the cabinet production line integrates nesting CNC machine, edge banding machine, and side drilling machine. The PVC door furniture production line combines CNC nesting machine, CNC wood sanding machine, and vacuum press machine. A cabinet door production line may include the computer beam saw, automatic edge banding machine and hinge drill machine. Besides, there are also other CNC machines for furniture making, such as sliding table saw, six-sided drilling machine, corner rounding machine, etc. All the furniture CNC machine can be combined according to your process needs to realize your furniture CNC projects.

Kitchen cabinet door making machine wood door making machine,Full automatic wood kitchen cabinet door making cnc router machinery .We can customize the most suitable machine for you according to the materials you process and the production process, such as changing the working size, changing the spindle, table, motor, etc.

IGOLDEN BLOG

Thank you for visiting the iGOLDENCNC website. iGOLDENCNC is the professional supplier of CNC machinery application solution, within the business of producing and selling CNC machinery and accessories.